Plastic Mold Industry Sector; It has developed with the widespread use of plastic. Our company, which follows these developments closely, has made many improvements and updates in the field of plastic mold / injection mold.

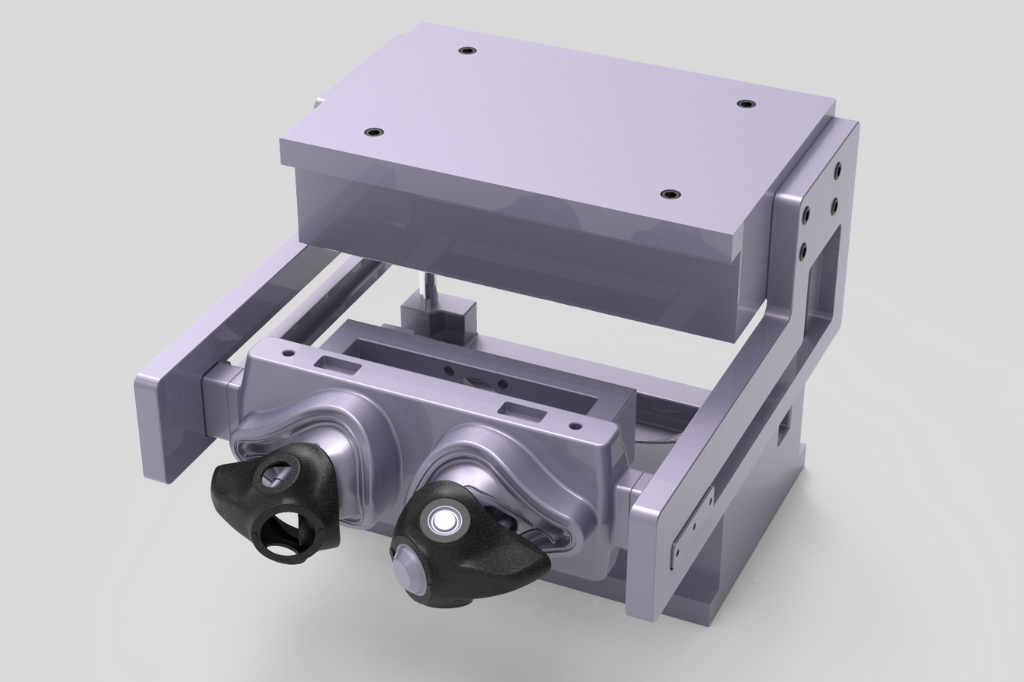

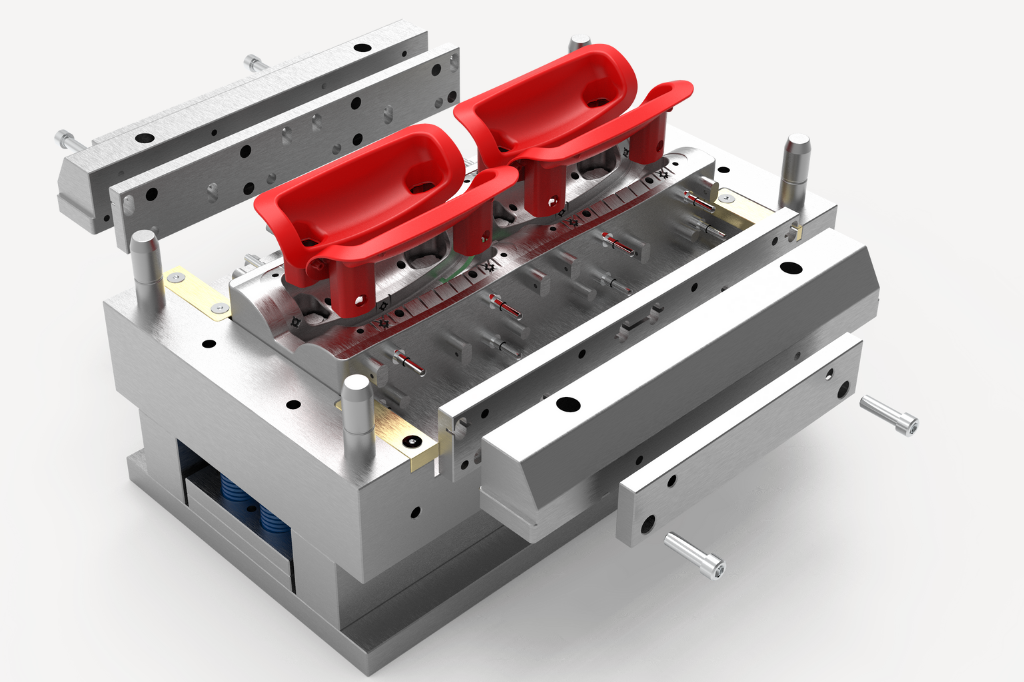

By directing the design process, which is completed with great care, to the machine park, the necessary mold set for mold manufacturing is ordered. The raw material of the incoming mold set is selected according to the product and product type. Quality and efficiency are kept at the optimum level in works that require high precision. In addition to injection molds, AYBERKSAN Kalıp Sanayi also produces zero split lines, hot runner mold, blow molds, rubber press molds, and insert molds.

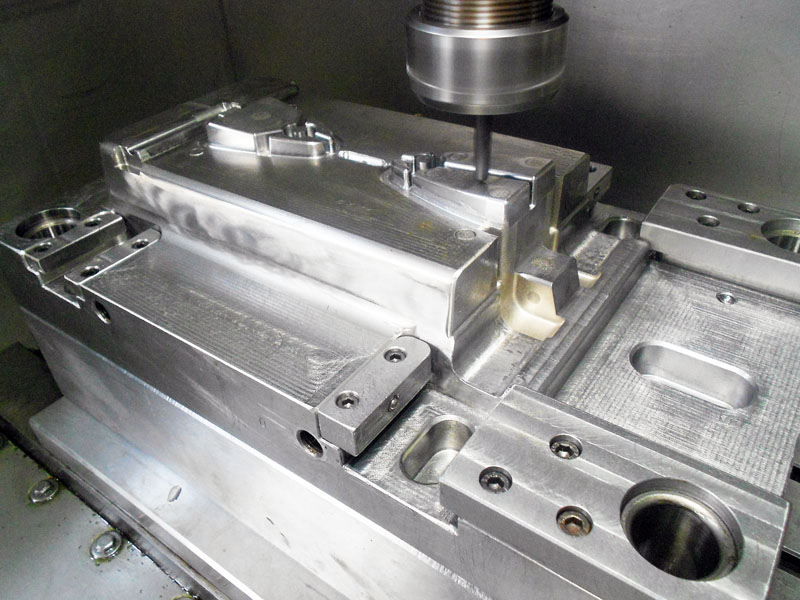

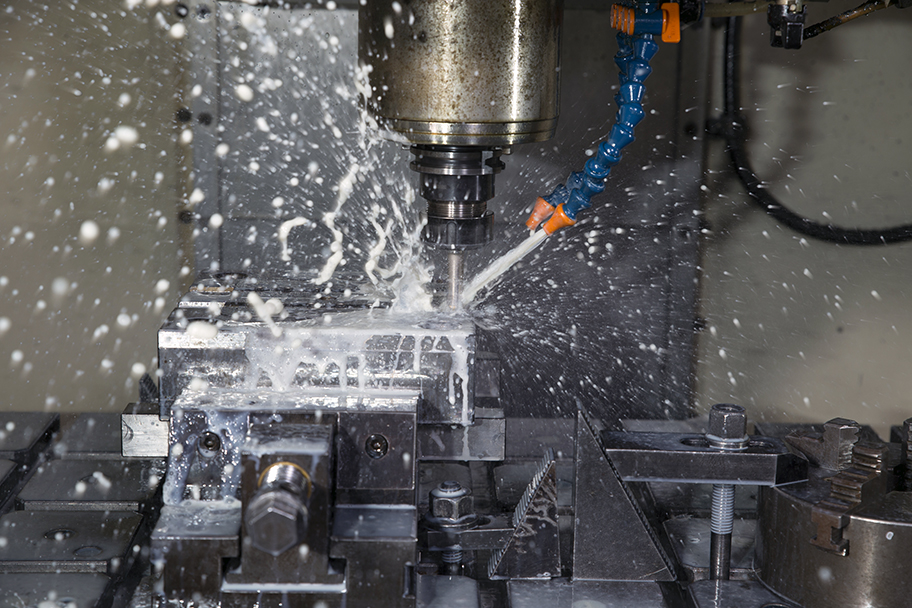

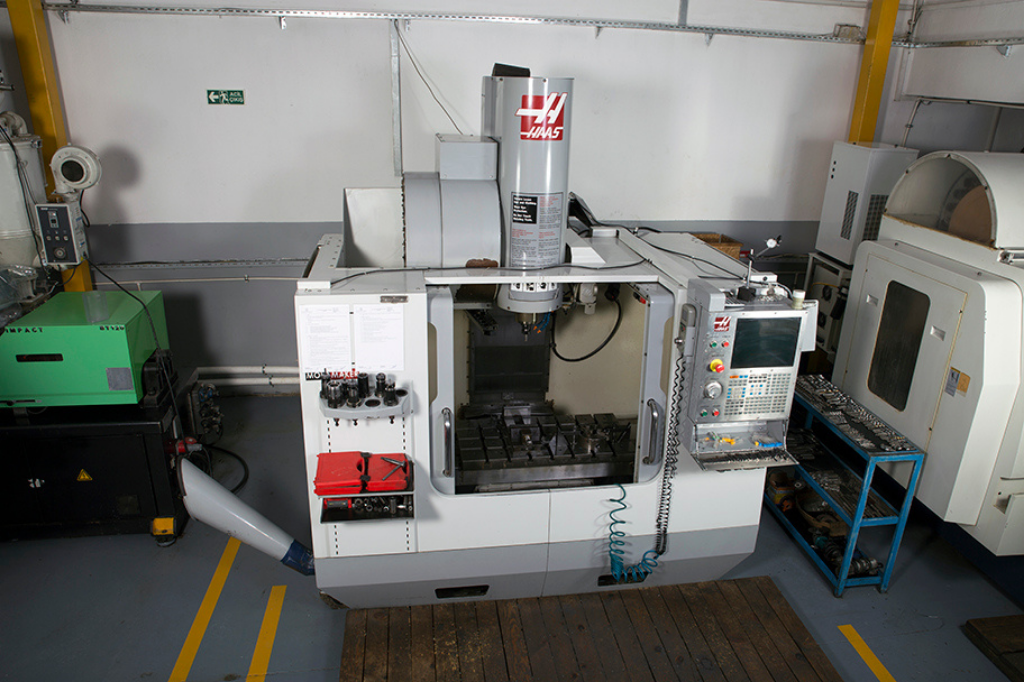

The mold designed in the CAM phase is programmed for processing on CNC machines. At the same time, the processes that require dimensional precision are reviewed again. After programming, the mold is processed on the CNC machine. Milling machines are used for slots and ejector pins, EDM plunge erosion is used for surface treatment. Before the injection mold is set up, the moving parts are checked for the last time. After all inspections, the mold is set up and sent for trial injection.