How Does Plastic Injection Mold Work?

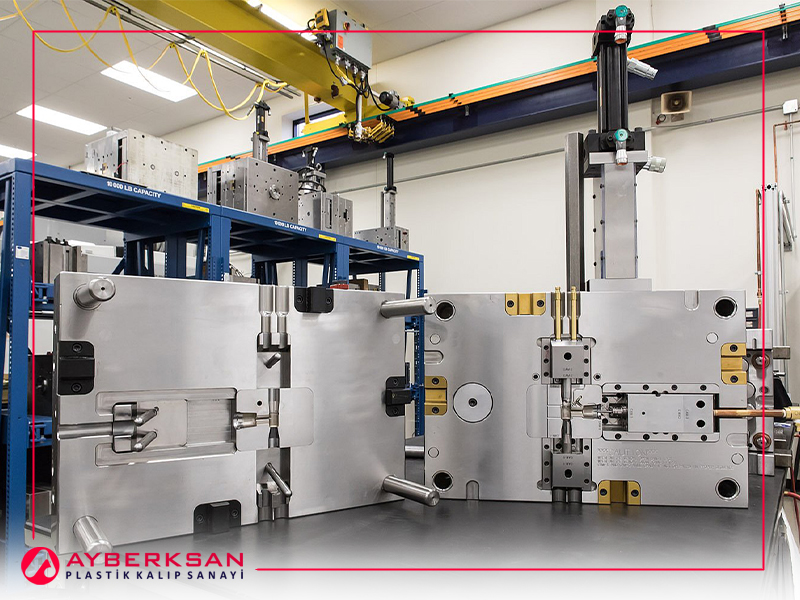

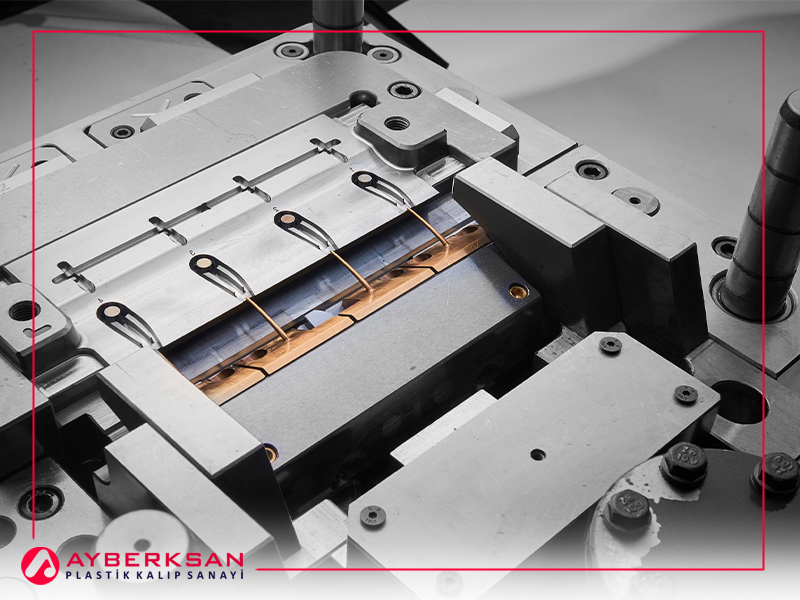

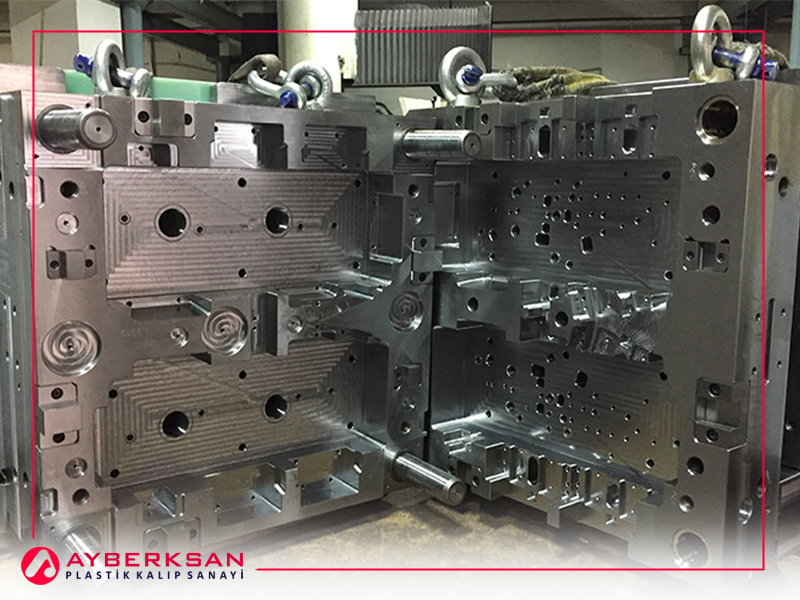

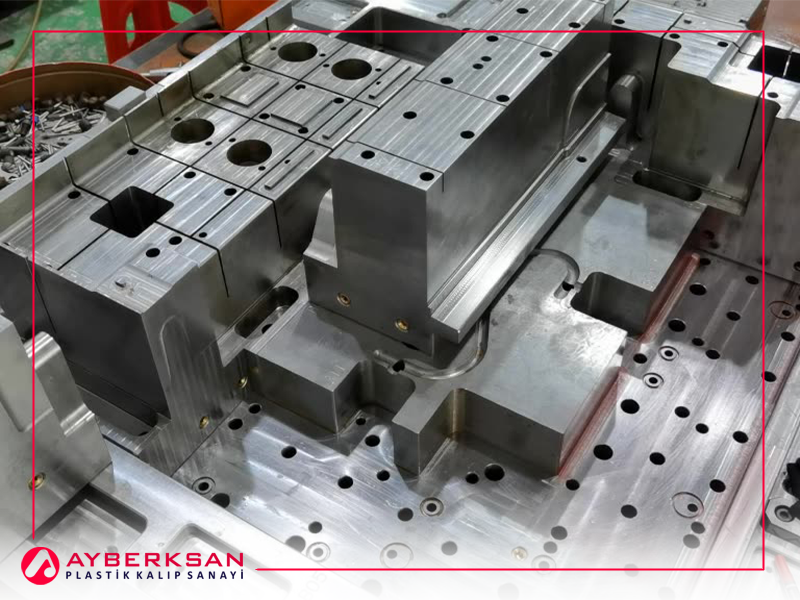

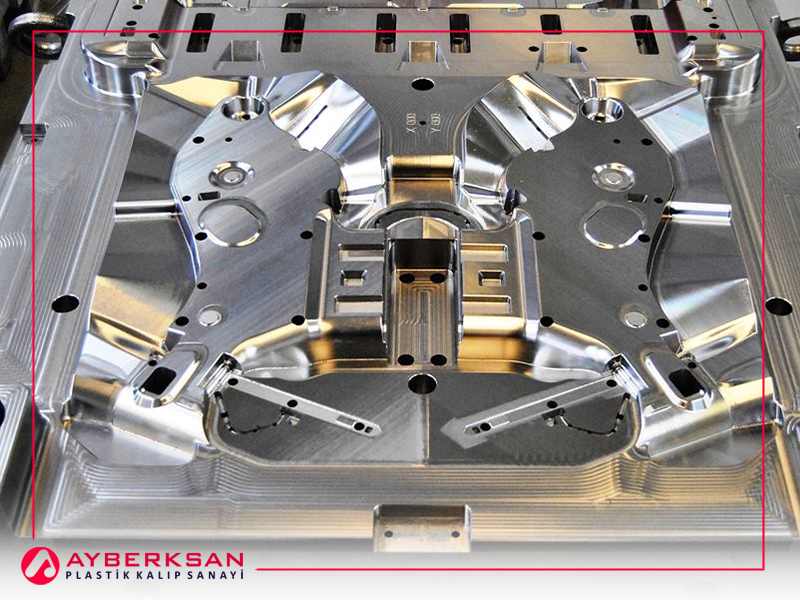

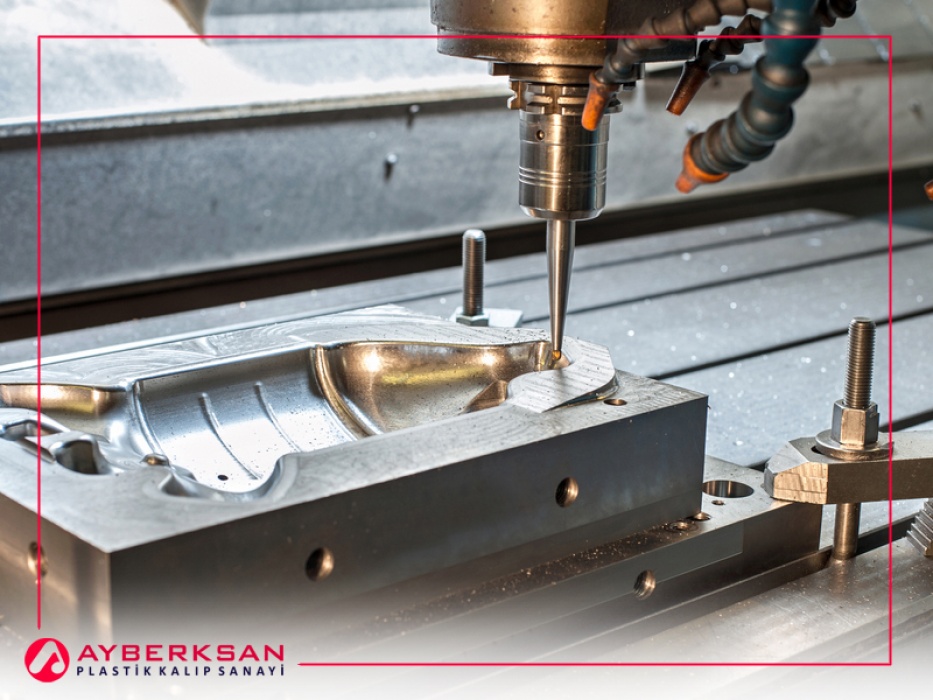

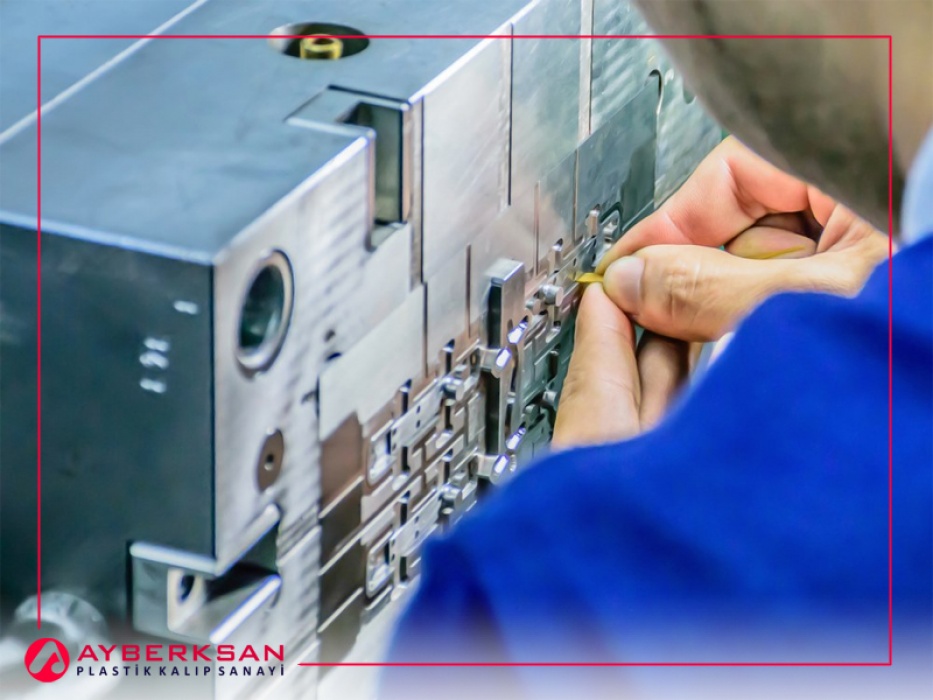

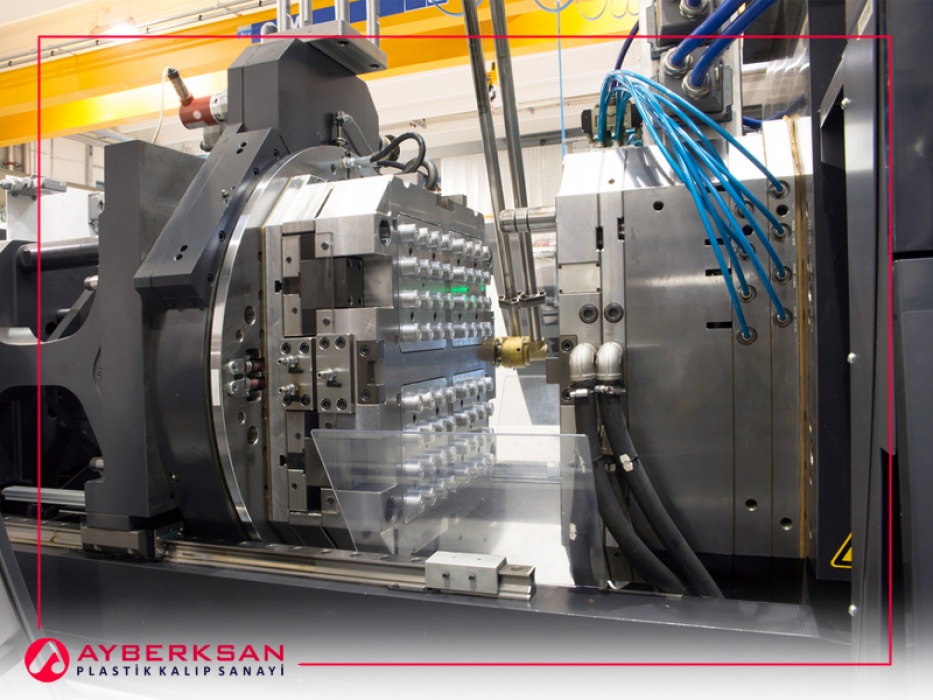

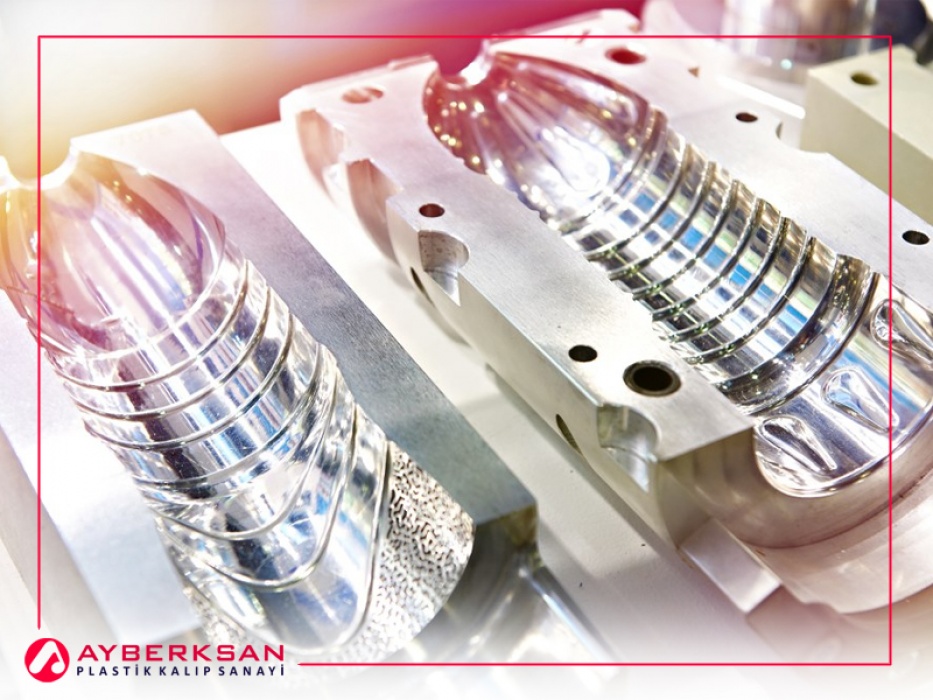

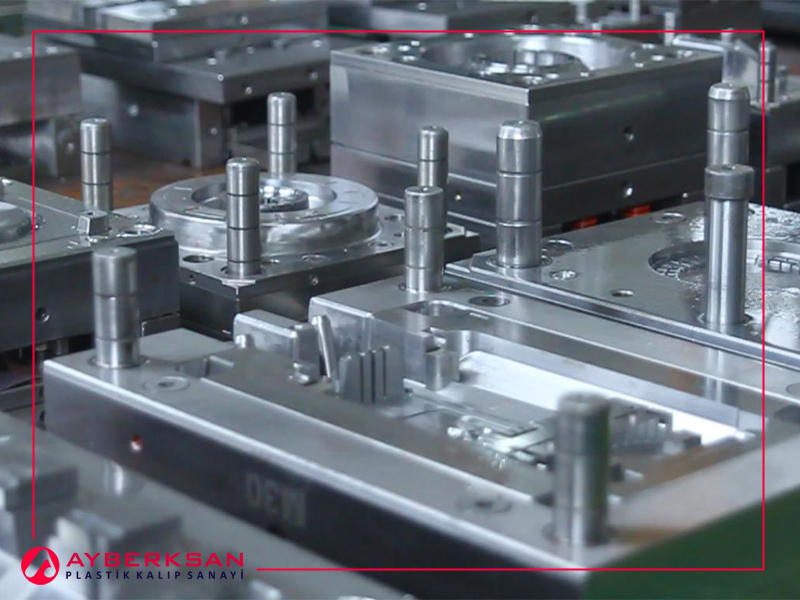

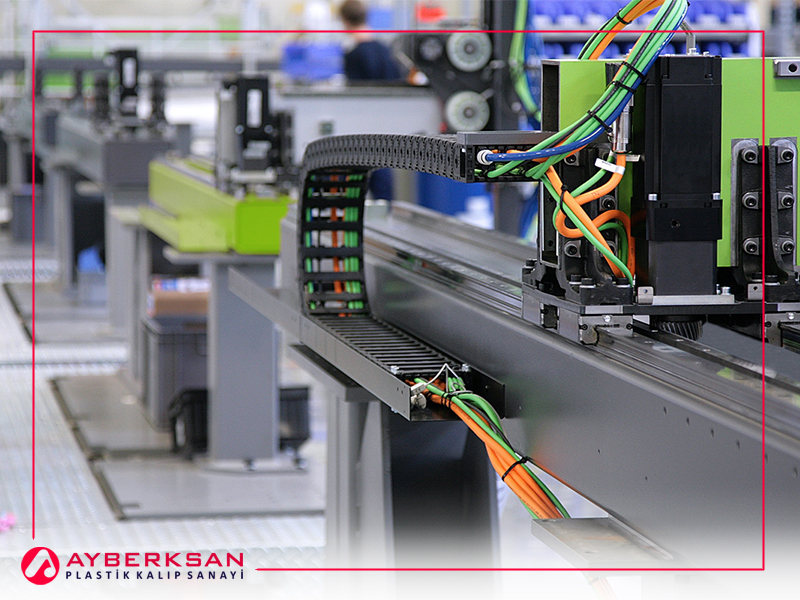

A plastic injection molding machine has been developed to inject large quantities of molten plastic into the mold at the right temperature at the right time to obtain any product. This process is very similar to metal casting, which has been known for a long time. An injection molding machine basically consists of a compression part with a piston inside and a ladle and screw injection parts for melting the granular plastic. It is recommended that these machines be controlled by the right tool and qualified persons. The movable plate is driven by a double-jointed arm and a cylinder. Mold factories prepare the shape you need in the most appropriate way so that you can produce it in the desired dimensions. Teams specialized in plastic injection molding make designs using 3D CAD surface and volume modeling software. The designed mold is created exactly on the CNC machine with the CAM program.

What is the Injection Molding Method?

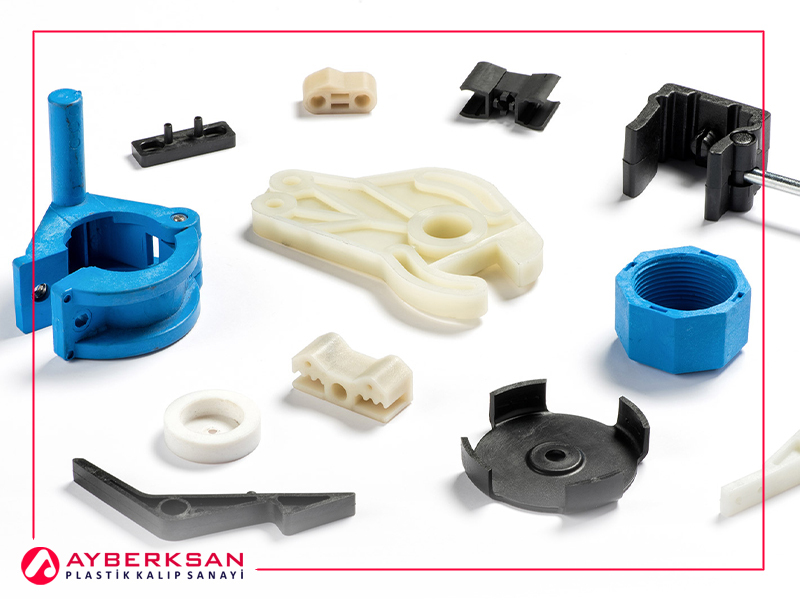

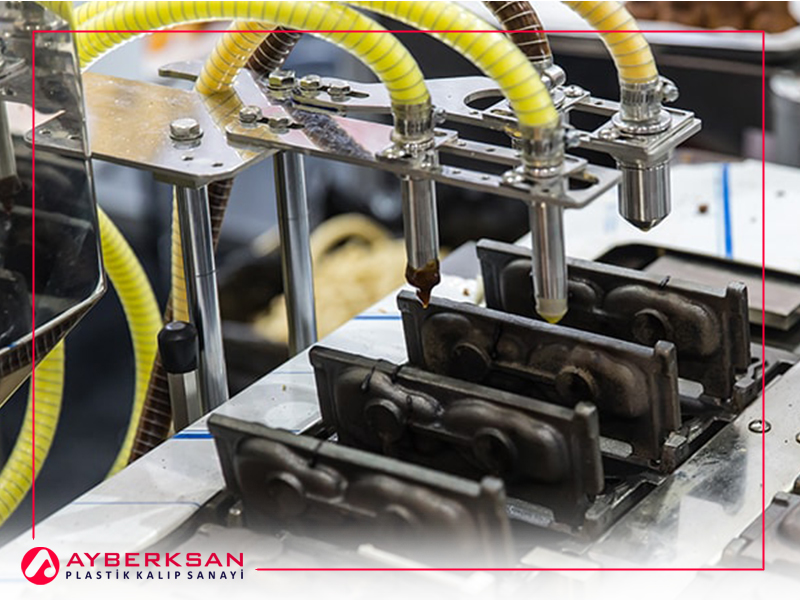

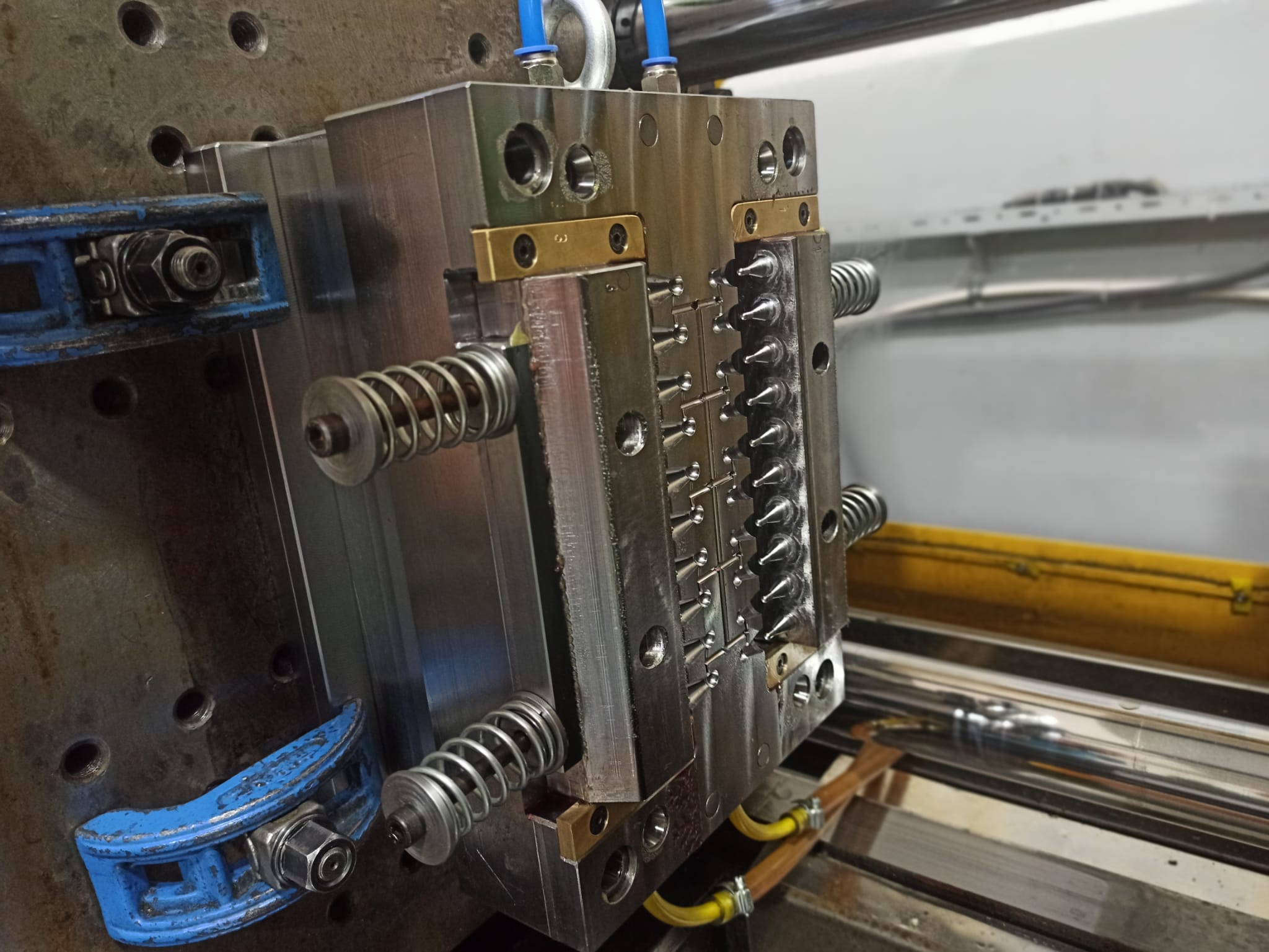

The injection molding method offers multi-part plastic parts and final product manufacturing services of all quality. Injection molding is the most cost-effective way to mass-produce plastic parts. During production, plastic granules are melted and injected into a precision machined mold. As a result, thousands of plastic parts are made in one mold, but every part is produced with the same quality. All this is available in a wide variety of material and surface variations. Injection molding produces wire spools, packages, bottle caps, auto parts, toys, some musical instruments, chairs and small tables, storage boxes, machines, and much more.

What Does a Plastic Injection Molder Do?

The shape and surface properties of the parts produced using the tool are transferred directly to the injection molded part. Generally, the initial cost is highest for injection molding. Because designing molds that can produce thousands of parts requires a high level of expertise. In this respect, the plastic injection molder processes the shapes, usually from aluminum or tool steel, with CNC milling and brings them to the desired standards. It is used in many industries such as injection molding, automotive, medical, apparel, electronics, and multi-part manufacturing. Almost all plastic products, large and small, that are frequently encountered in daily life, are produced using this process. Plastic parts for cars, computer cases, glasses, toothbrushes, and refrigerators are produced by injection molders.