Plastic Injection Mold Manufacturing

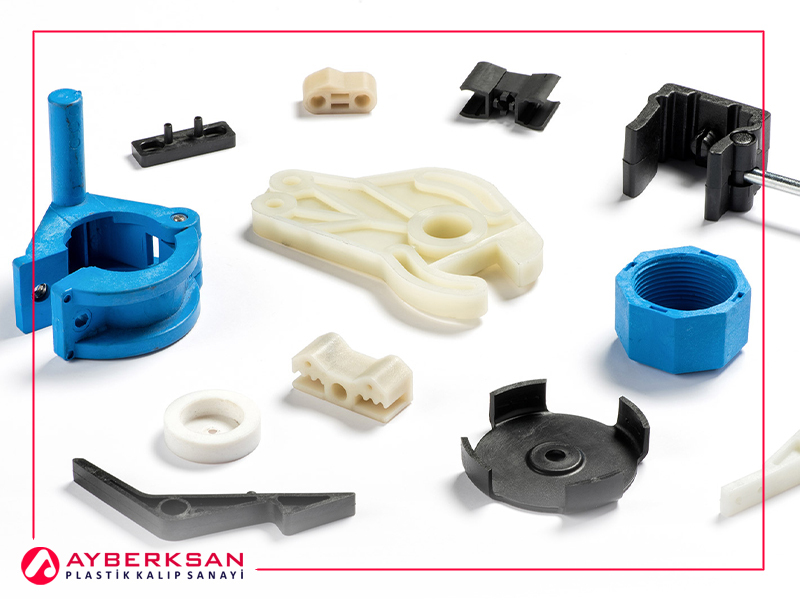

Plastic injection mold manufacturing provides plastics with reasonable mass production. Mold manufacturing is most popular at this point. Plastic Injection molding is one of the activities that getting increasing. The timing is more important for mold manufacturing. Right measuring provides big advantages of the production line. Today, plastic products are seen almost everywhere thanks to the common use of plastic molds. For example, furniture, computers, sports equipment, etc. The most important tool is the molds of the production industry.

Plastic Injection Mold Technology

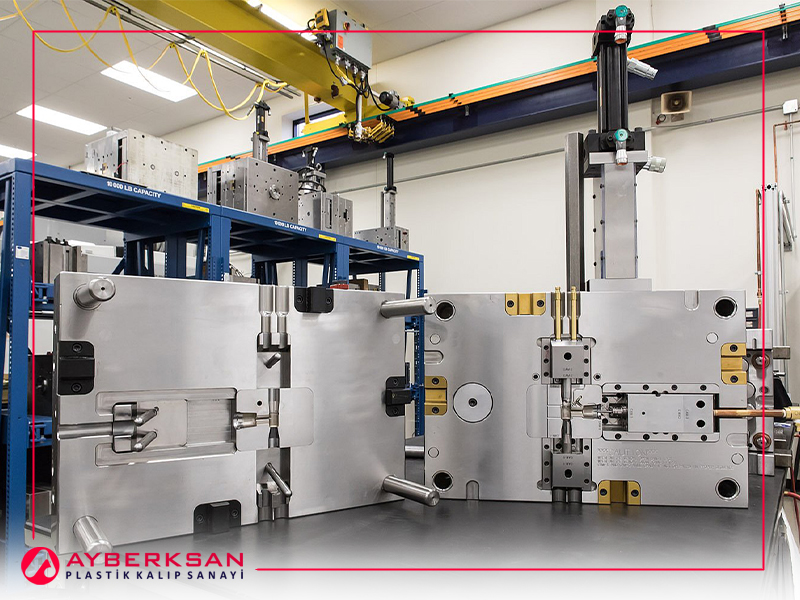

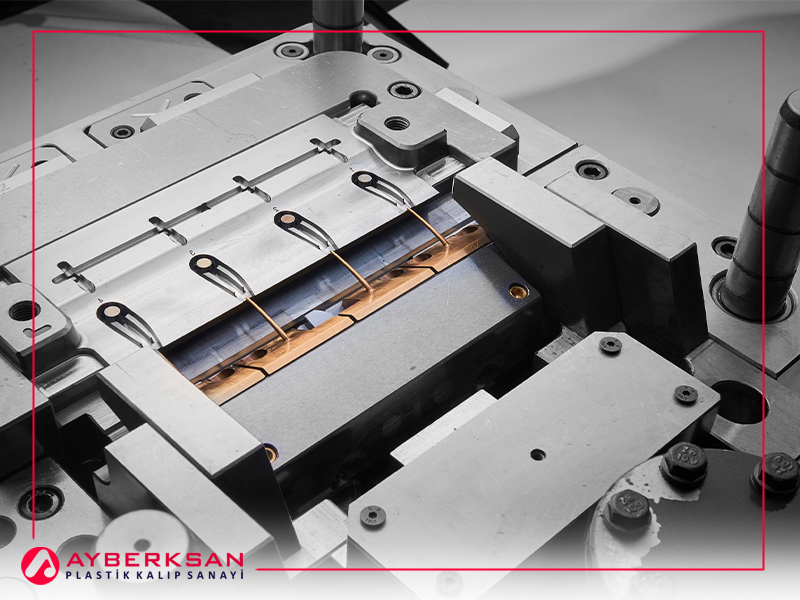

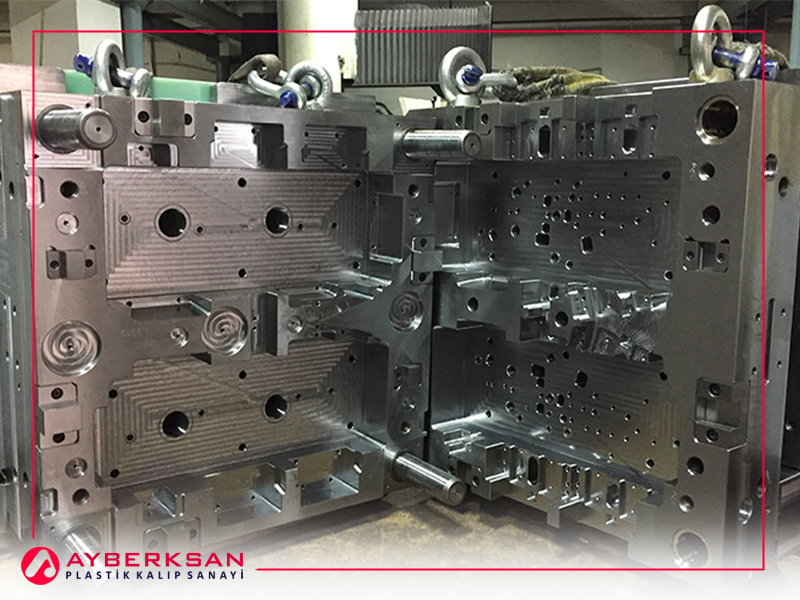

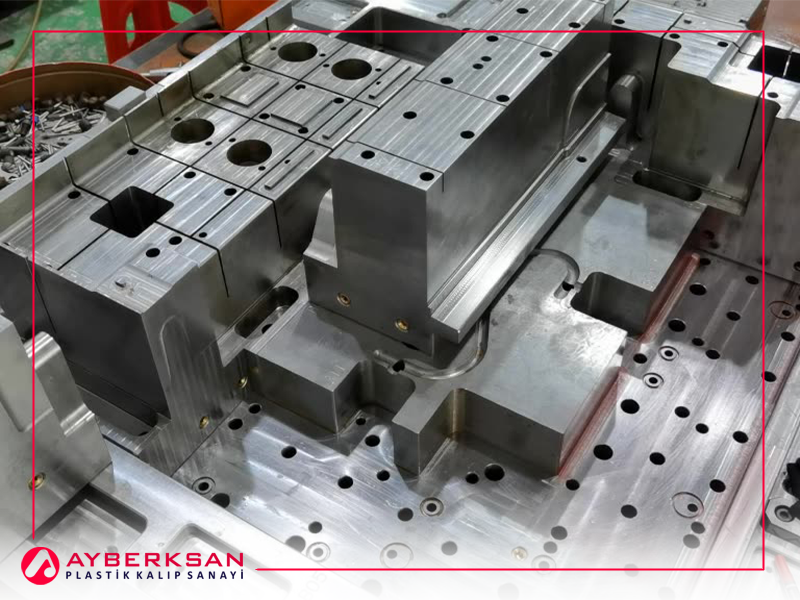

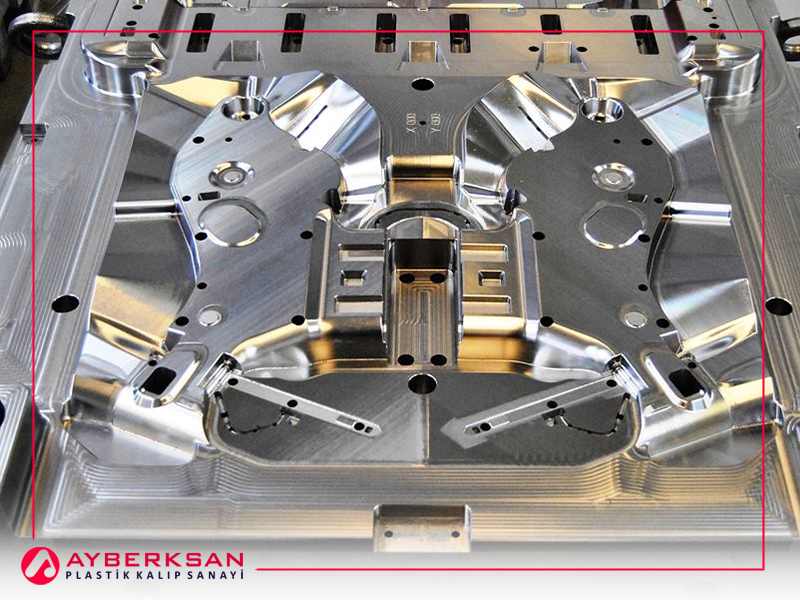

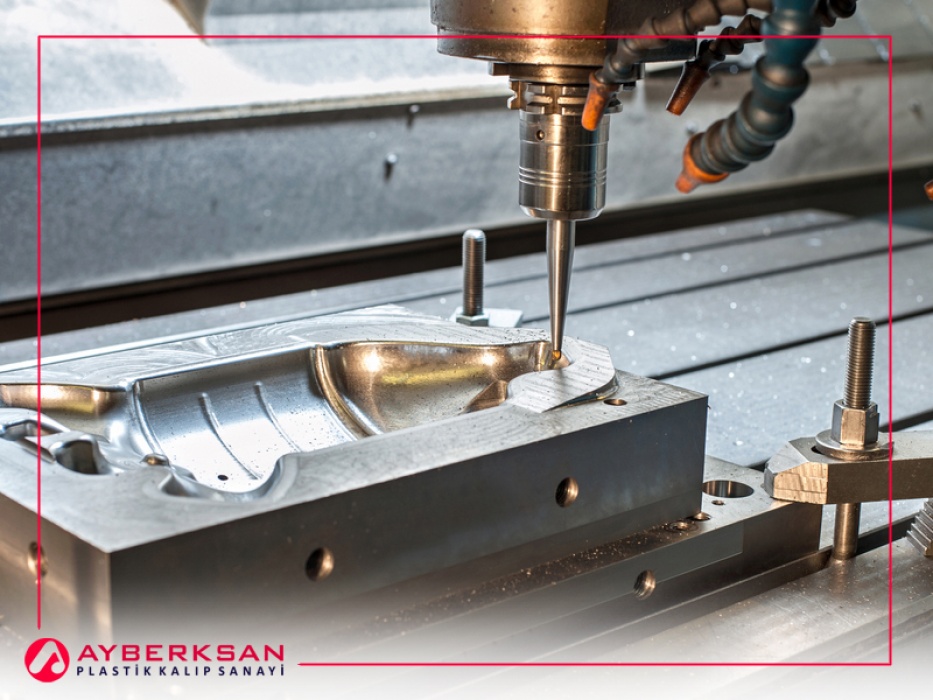

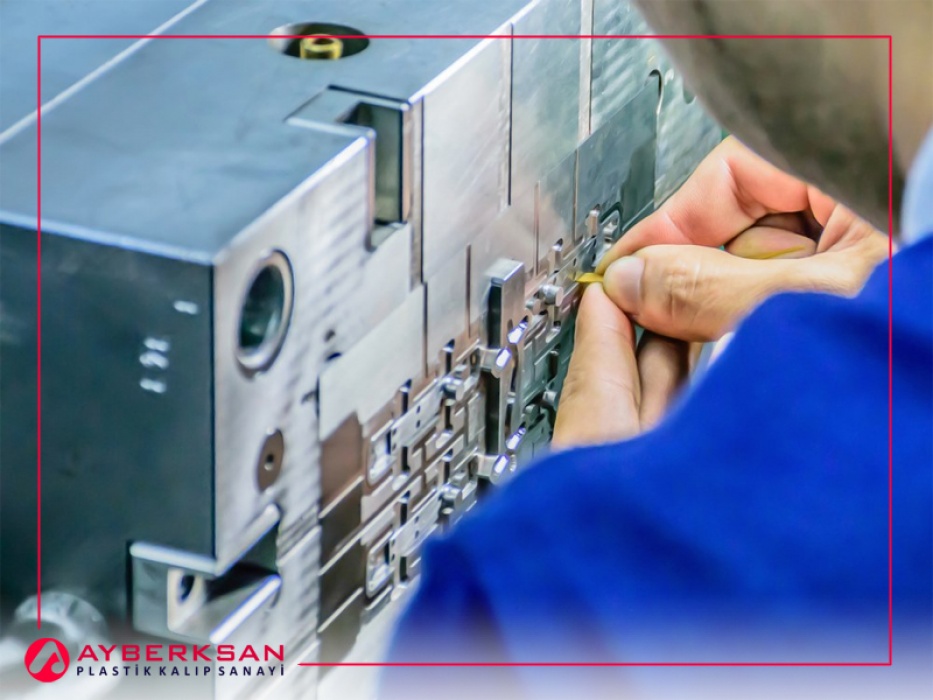

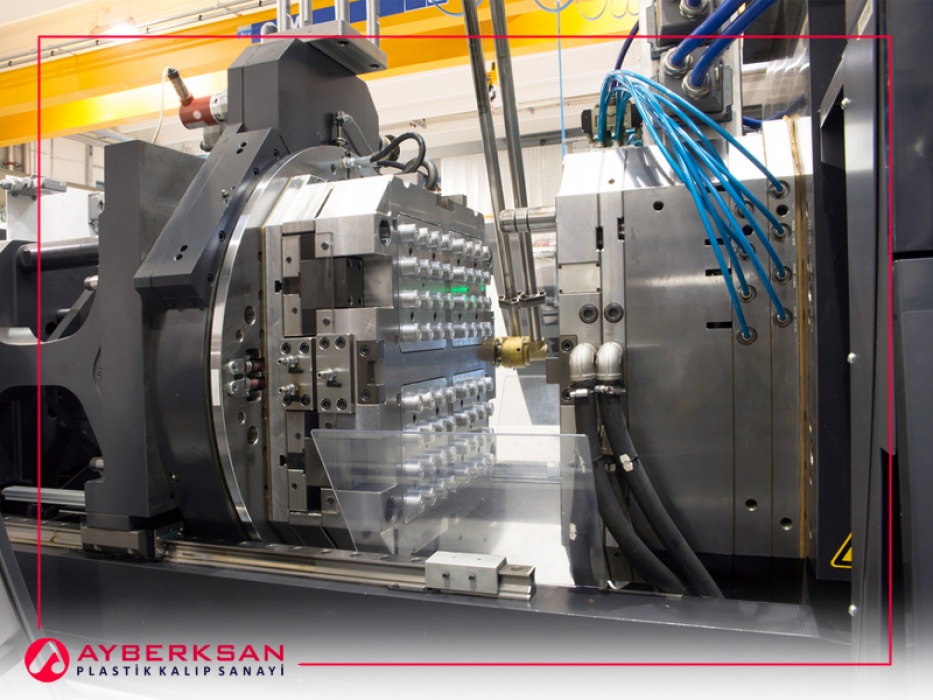

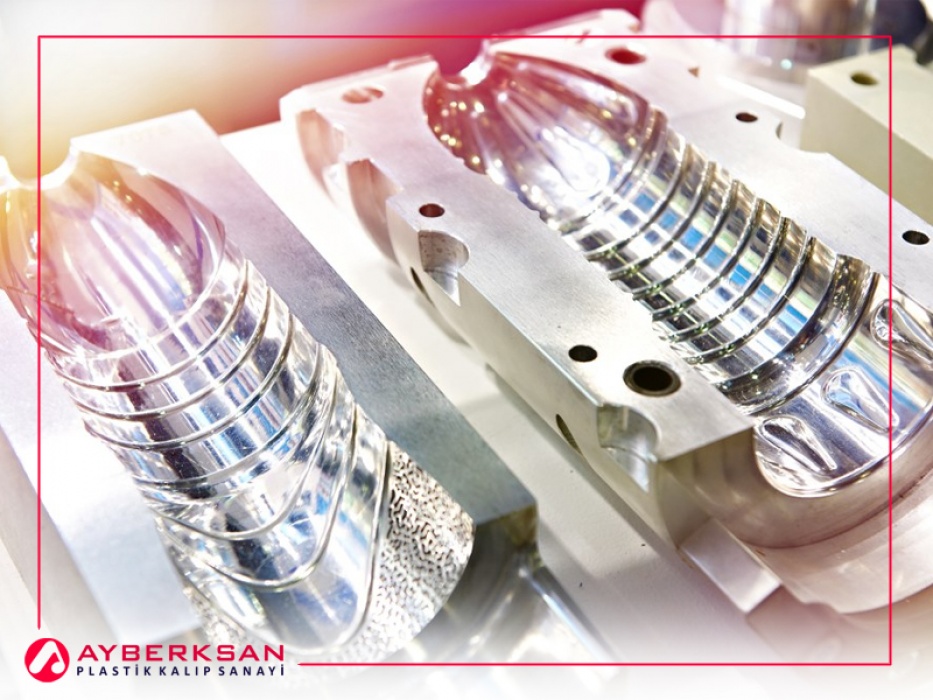

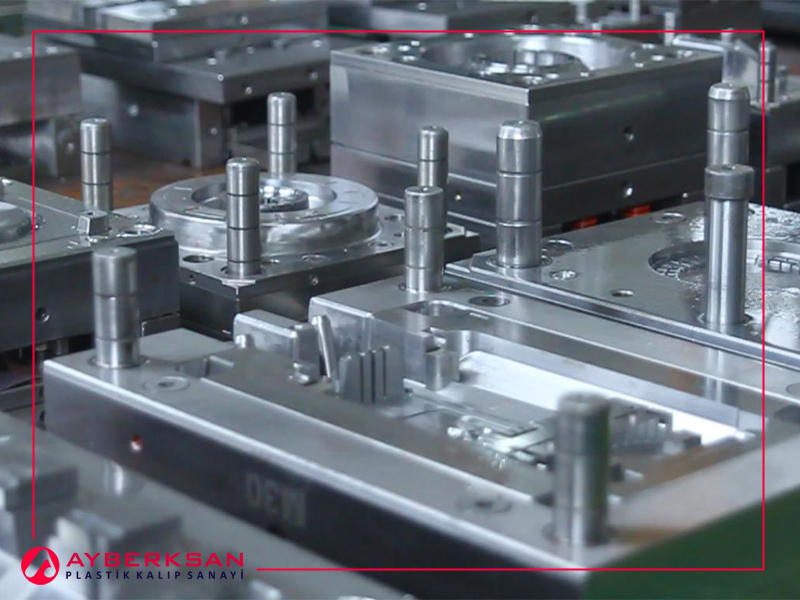

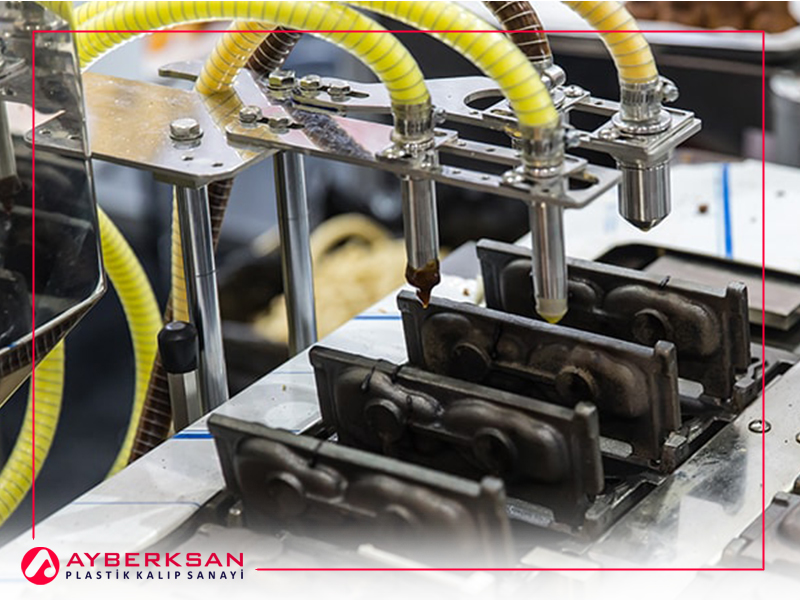

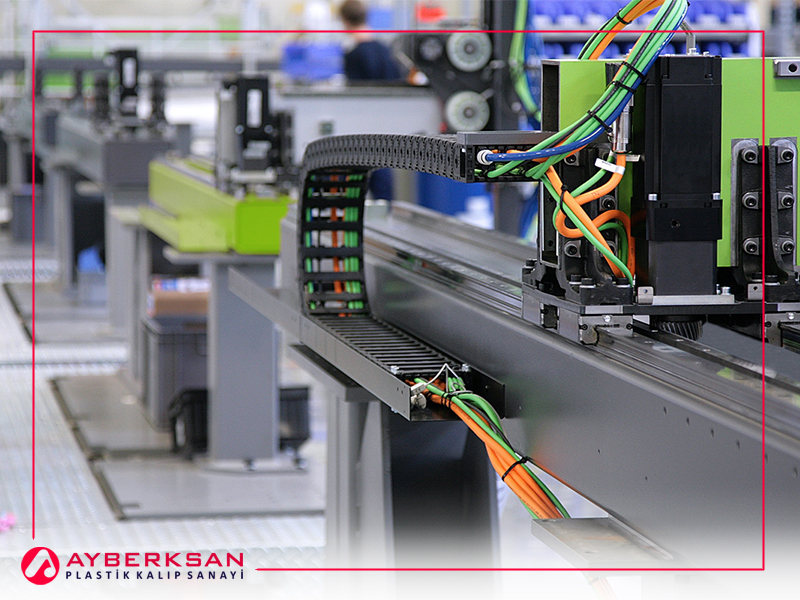

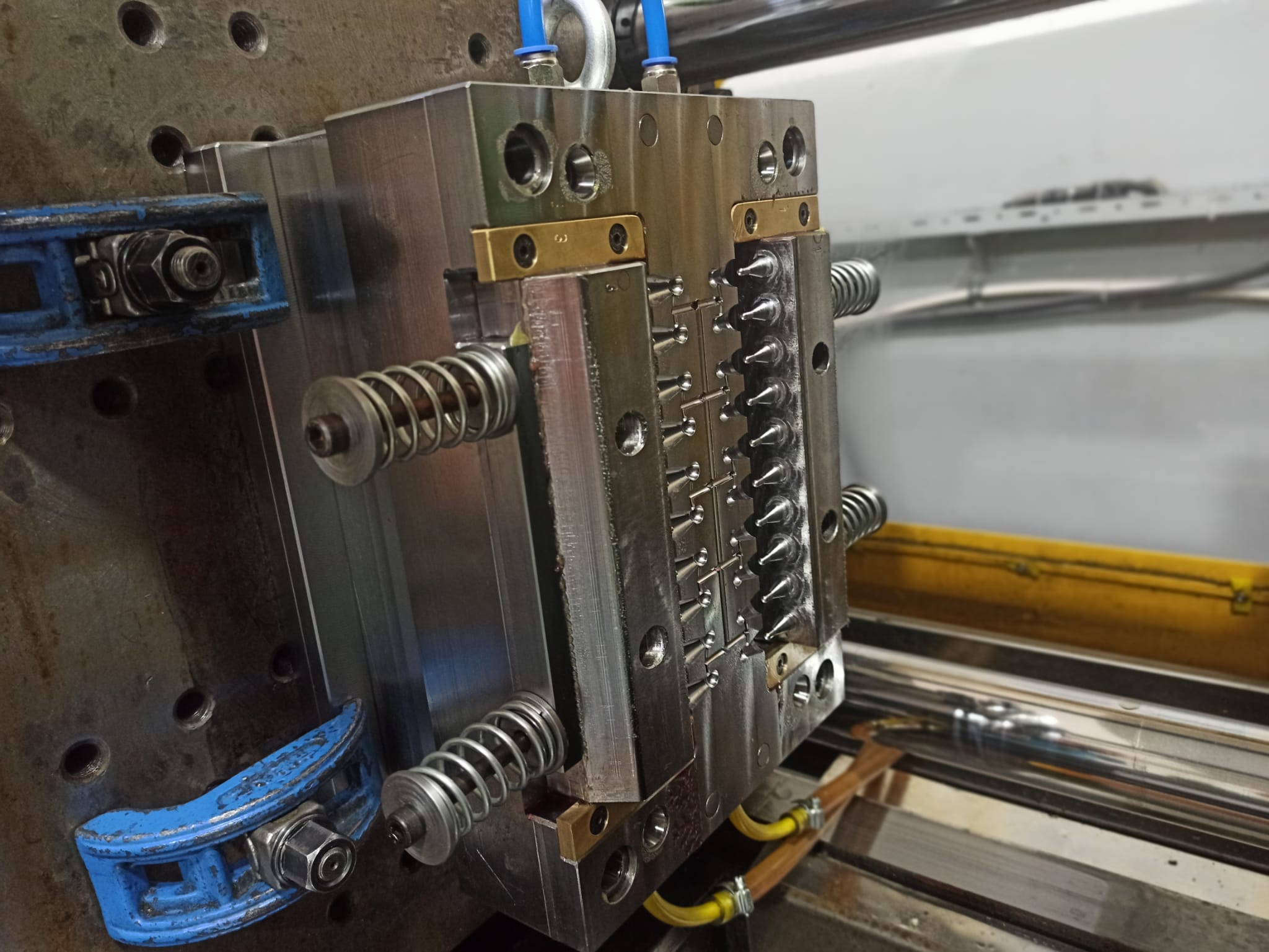

The plastic injection technology has been a process since 1872 that can be describe as plastic parts producing process from melted plastic injected a mold. This technology process is complex. First, the engineer designs the mold that is suitable for the requested product. After that, the mold checking by the moldflow analyses. And the mold set sends the production line. After the CNC progressing, EDM, shining or surface finishing the mold assembly process start. Also, it needs some tests from the designing to the mass production. The plastic mold test is getting time that is in the final levels of molding. After the sample products approved the mass production starts.

The Importance of The Injection Molding

Due to technological developments, mold making, and machine mold business is getting bigger and bigger nowadays. Plastic injection molding is very important as it enables the manufacture of many parts in your daily life. It reduces labor costs to a minimum by saving time, quality and materials in the production process of these products, which are frequently encountered in daily life. Although the main purpose of the plastic injection molding method is not different from reducing the costs, it can vary according to the working system and the product created.