How is Plastic Injection Production Made?

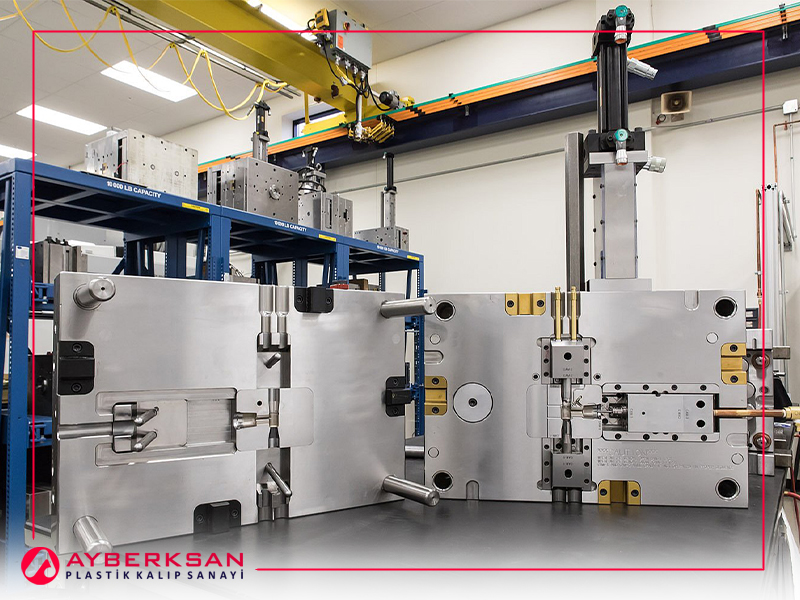

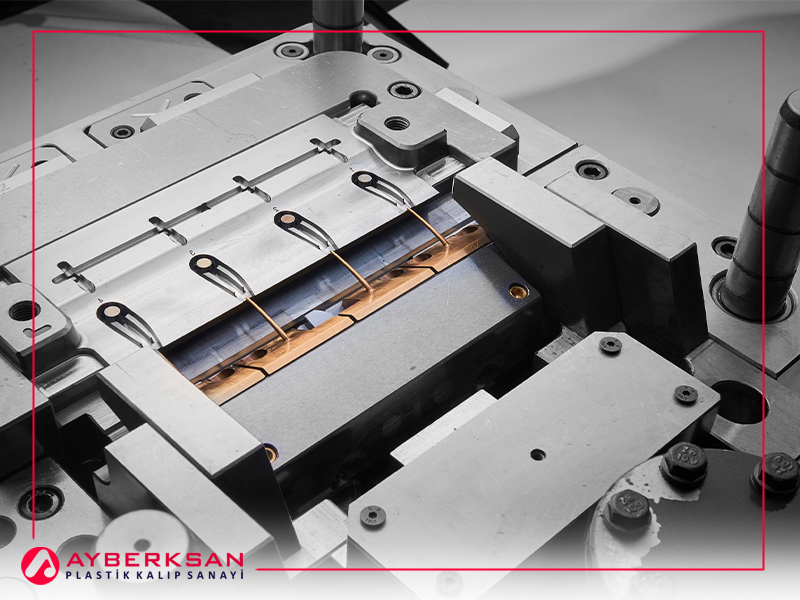

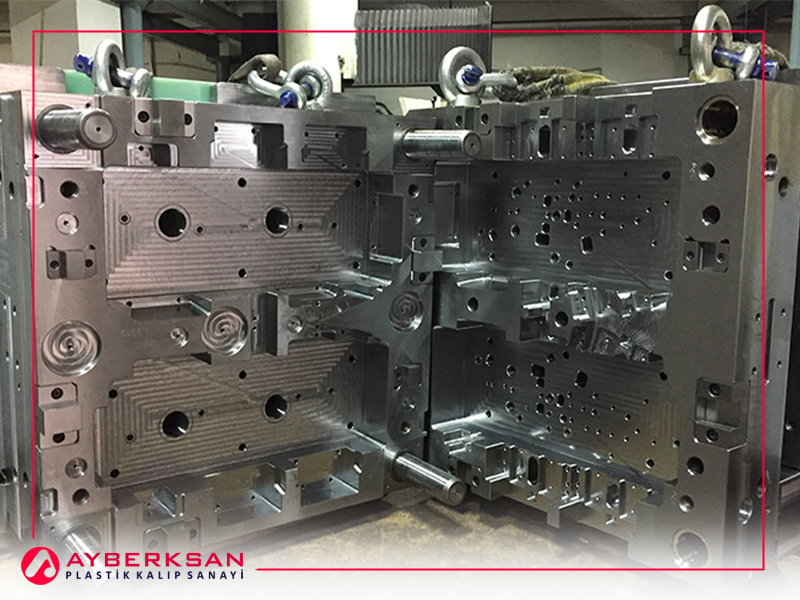

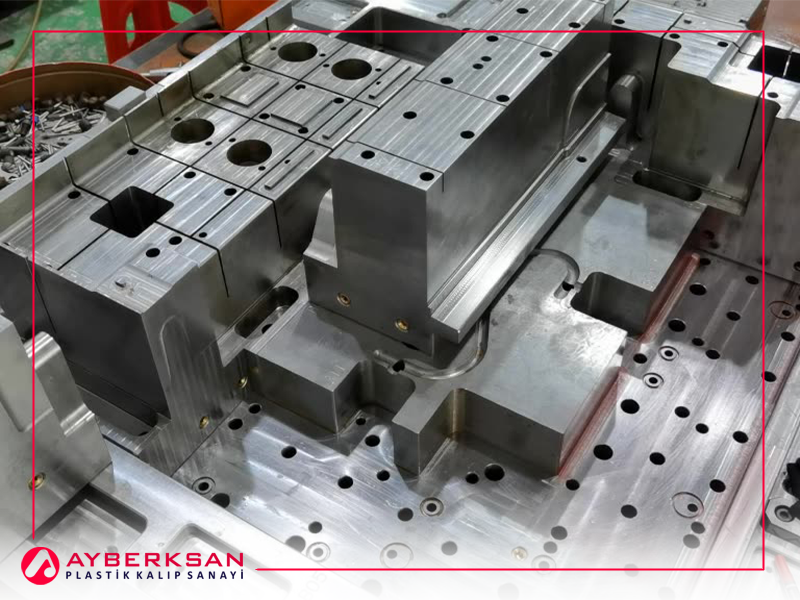

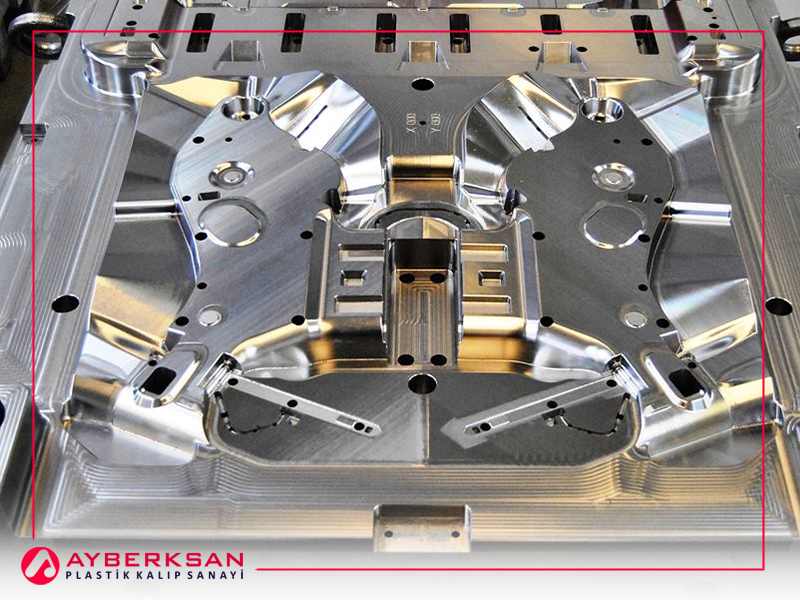

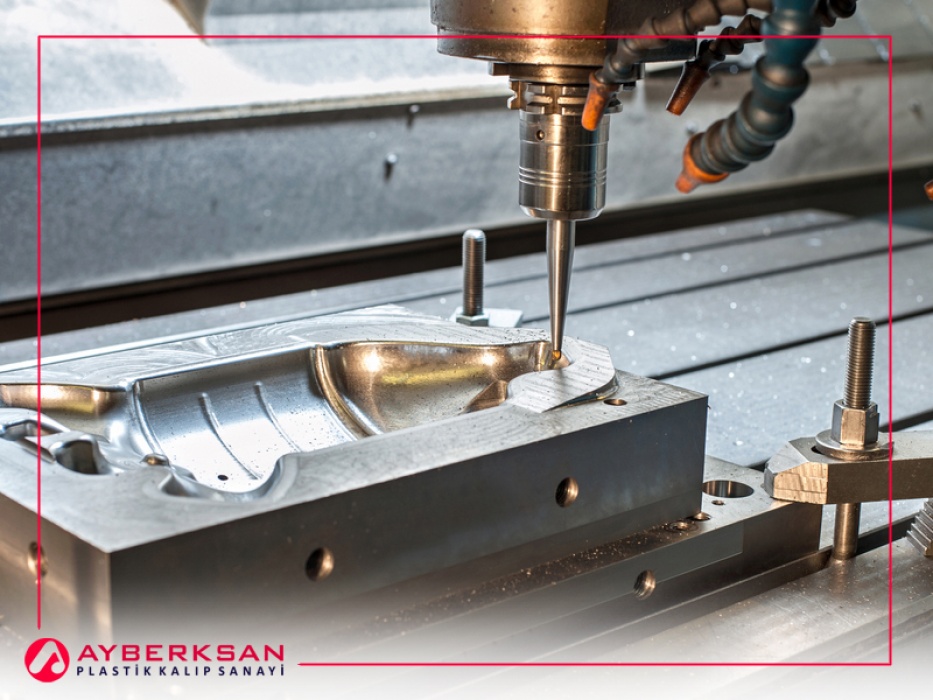

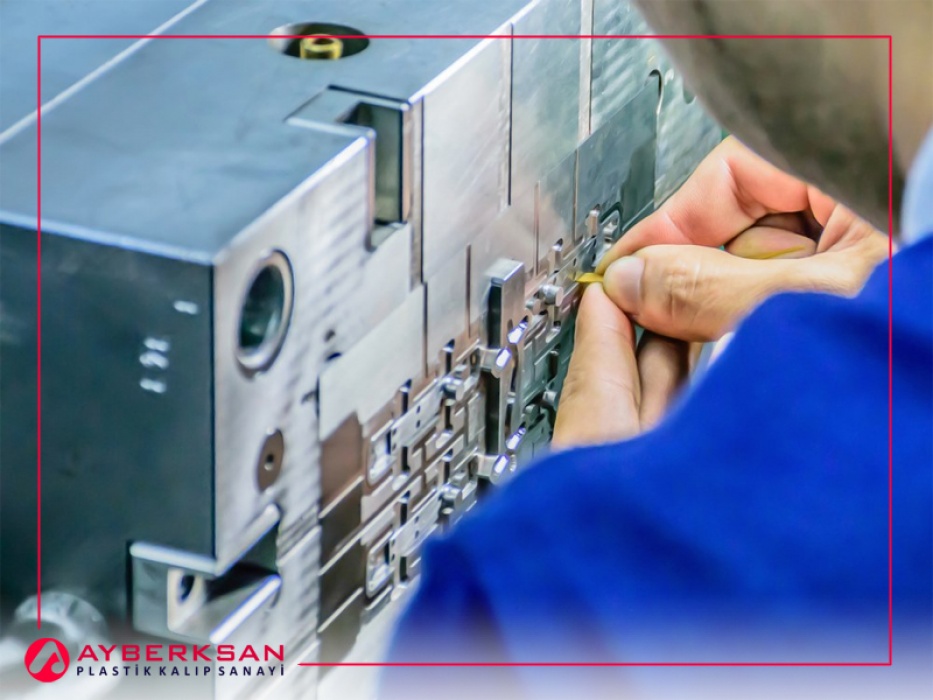

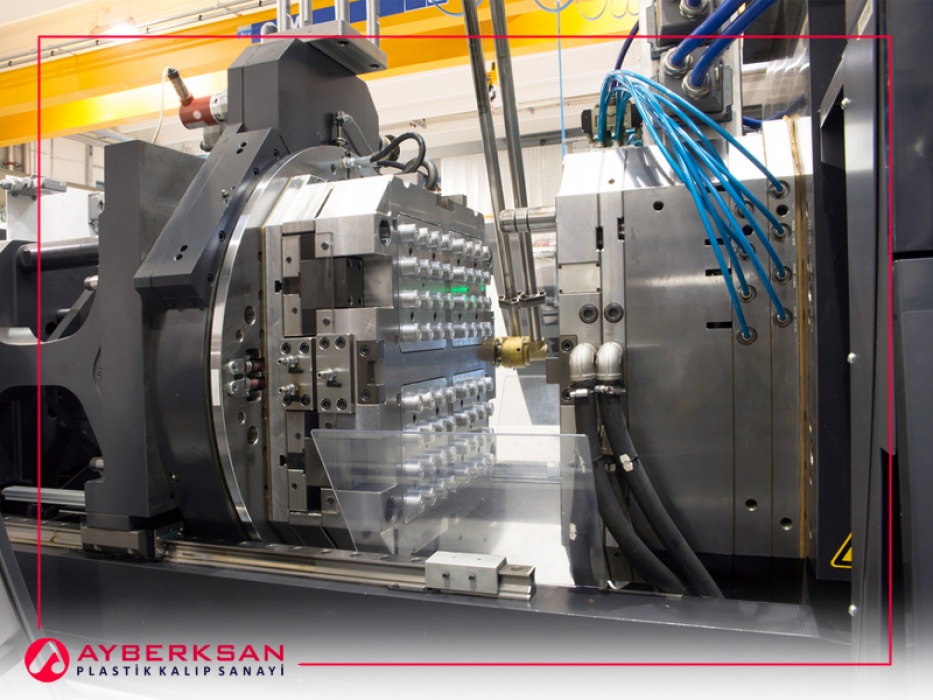

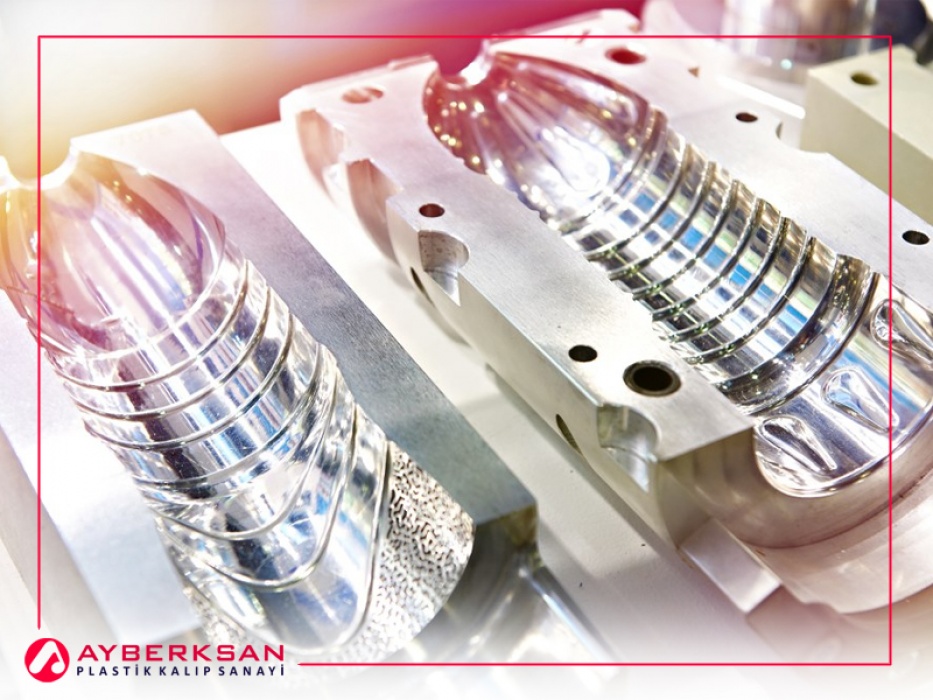

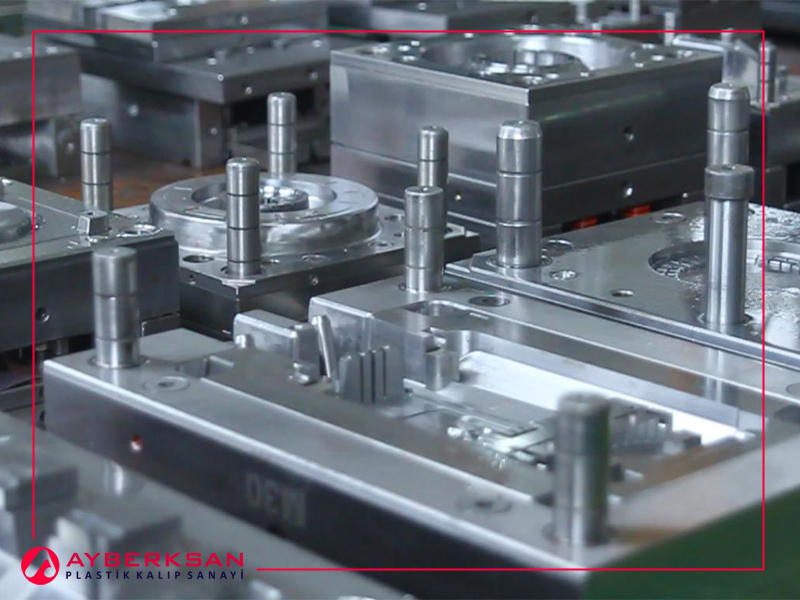

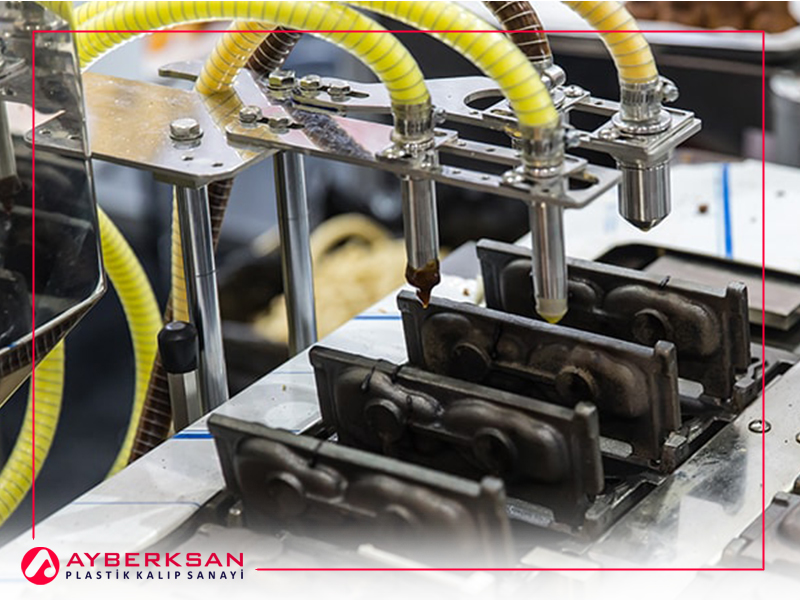

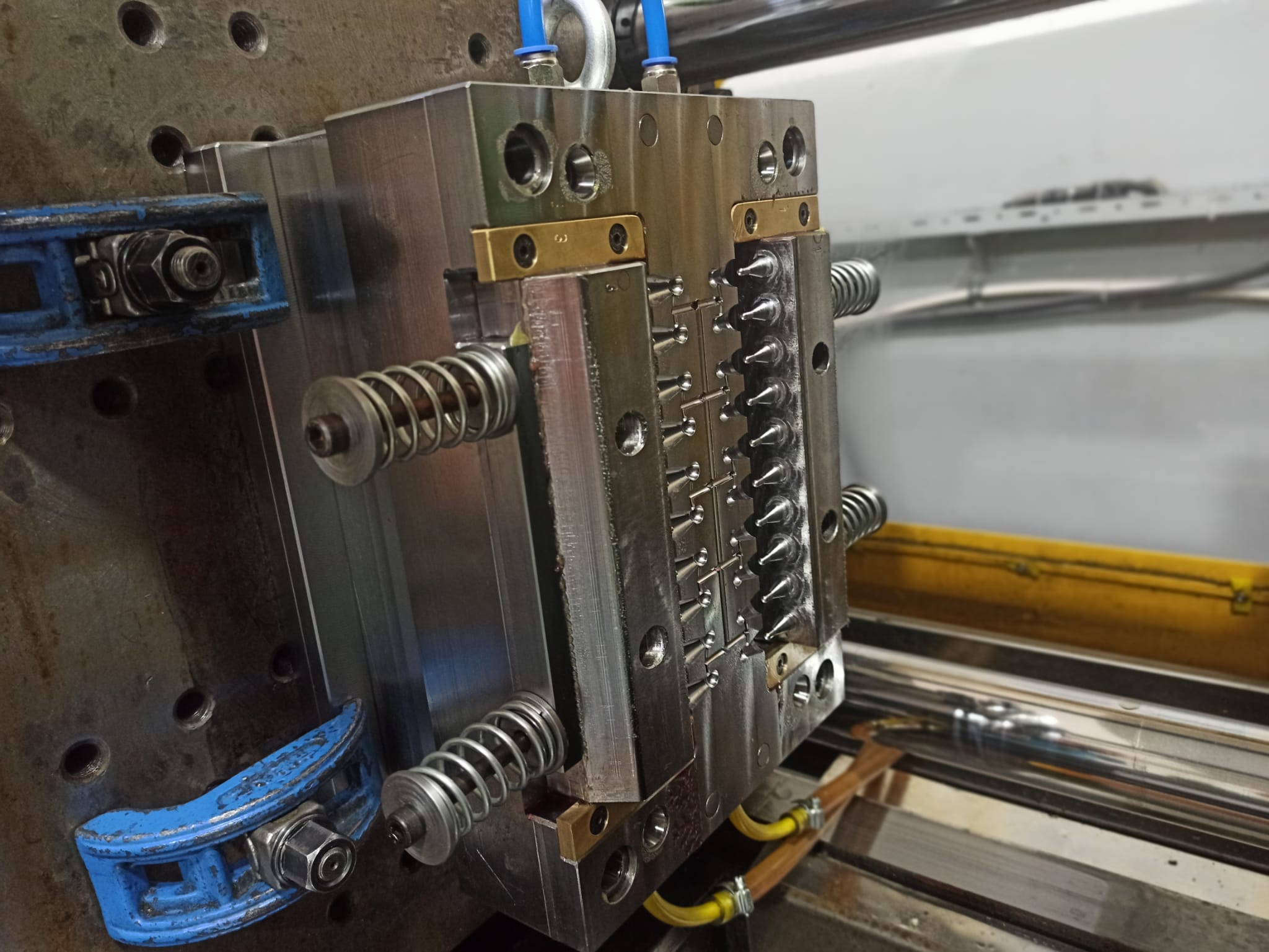

Plastic injection molding is the process of injecting molten plastic raw material into a mold using heat, cooling it, and removing it from the mold. This process makes it possible to produce plastic parts of various sizes and classes for many industries. Injection molding machines typically consist of injection, vise, control unit, and drive system. The vise unit provides the closing, locking, and opening of the mold. The injection unit provides melting of plastic material by heating and injecting the molten material into the mold. The control unit, on the other hand, controls the barrel temperature, molten material temperature, mold temperature, screw rotation speed, etc. where transactions are made. The drive unit is the system includes the joint locking mechanism and the ejector mechanism. After the plastic materials are injected into the mold and completely filled the mold, the molten material is cooled by the water channels in the mold. With the activation of the pusher mechanism, the product is removed from the mold and then becomes usable.

Plastic Injection in Which Sector?

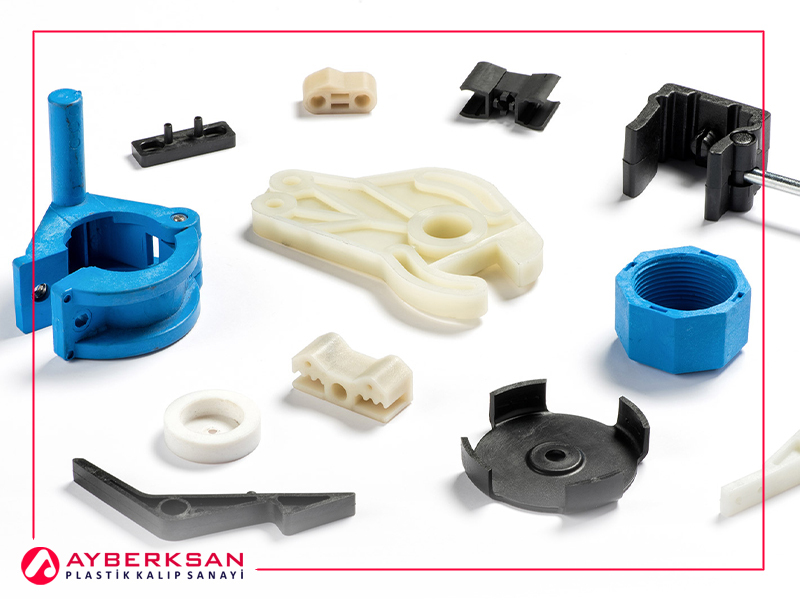

Plastic injection mold usage areas are mainly cooling, lighting, exterior, and building construction, shower cabinet, furniture and decoration, automotive, electricity, electronics sectors. In addition, plastic injection molding is used in areas such as plumbing, heating, packaging, and transportation. In addition, production is made by plastic injection molding in the supermarket, agriculture, water treatment, medical and defense industry sectors.

How is Plastic Material Production Made?

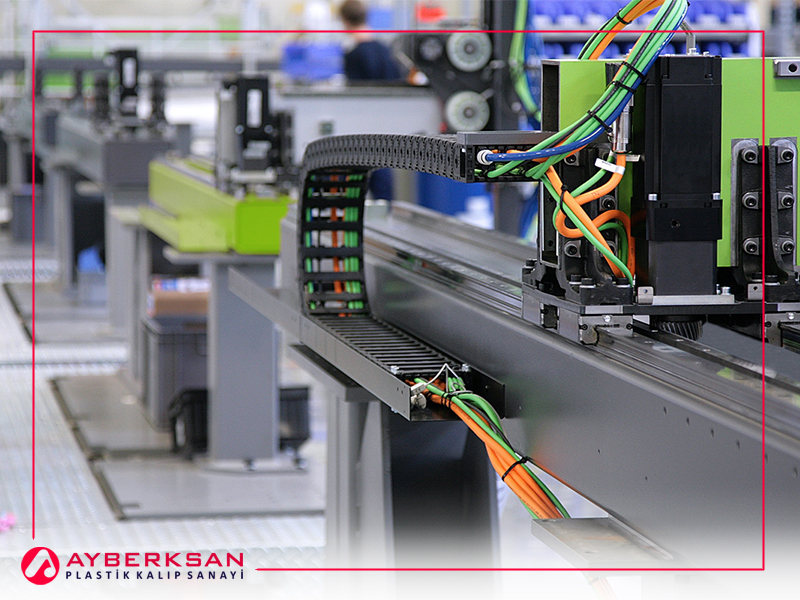

Plastic material production is generally done in three ways. Production is made by plastic injection, extrusion, and blow molding methods. High-tech injection molding machines can be used for the production of non-sterile or sterile products. Today, injection molding machines produce zero-electric and tie-bar-less machines, similar to the zero-electricity goal of automobiles. The most important features of these machines are their extremely high efficiency, long service life, and energy savings.