Plastic Part Manufacturing is a hard process that needs to right person and right machine.

What is Plastic Mold?

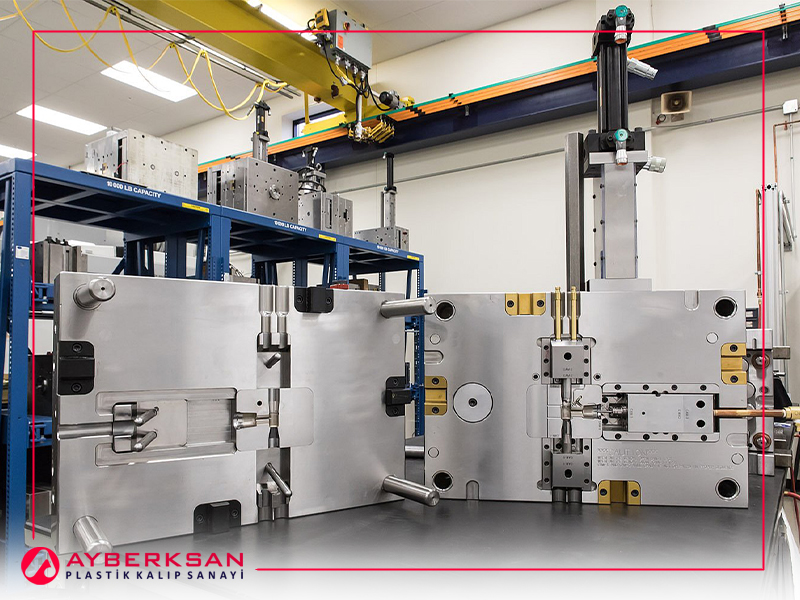

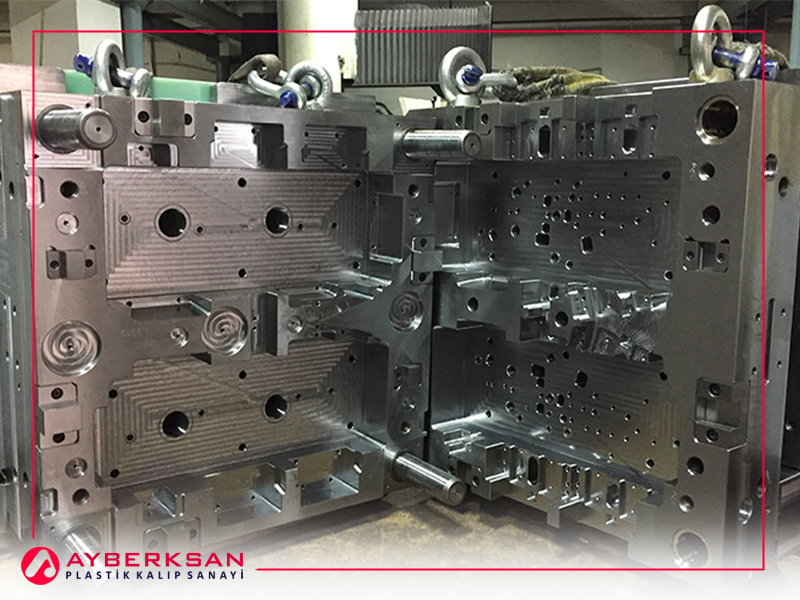

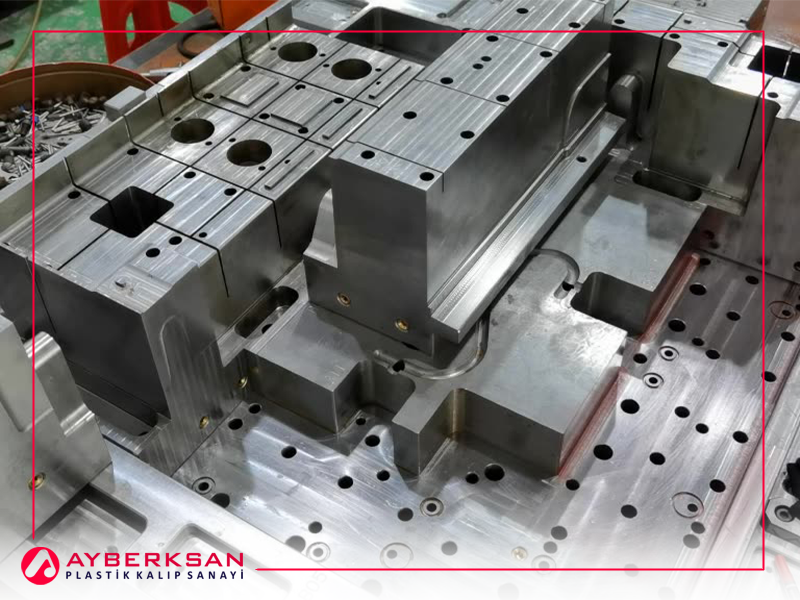

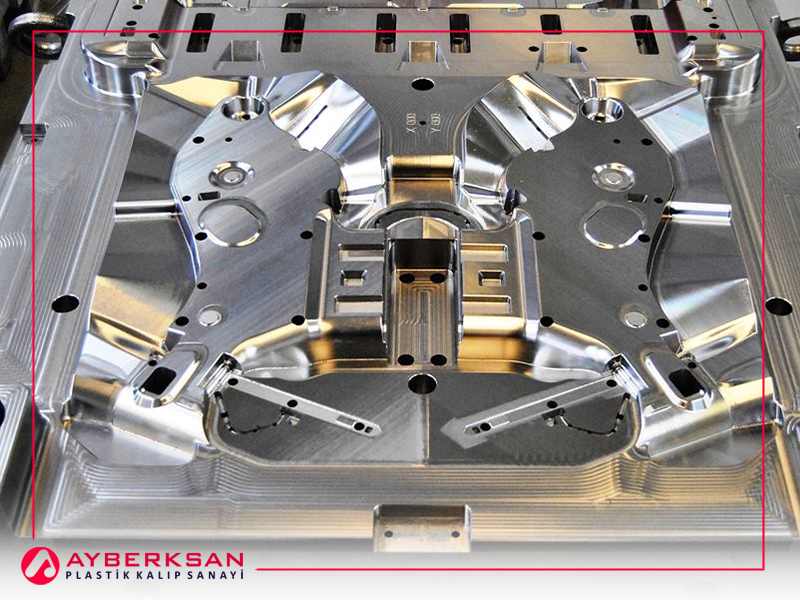

Designed in accordance with the geometry of the plastic to be produced, the number of products and the characteristics of the machine to be produced, the plastic mold allows you to produce plastic parts in precise dimensions. With the appropriate machine, it is ensured that the plastic raw material reaches the final product. Thanks to the production of plastic molds; features such as shape, durability, quality is determined.

How is Plastic Mold Manufacturing Done?

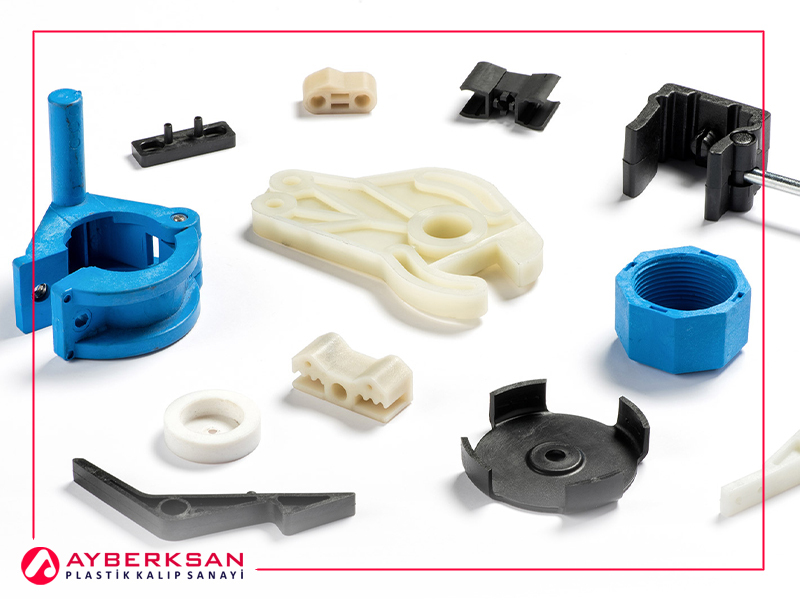

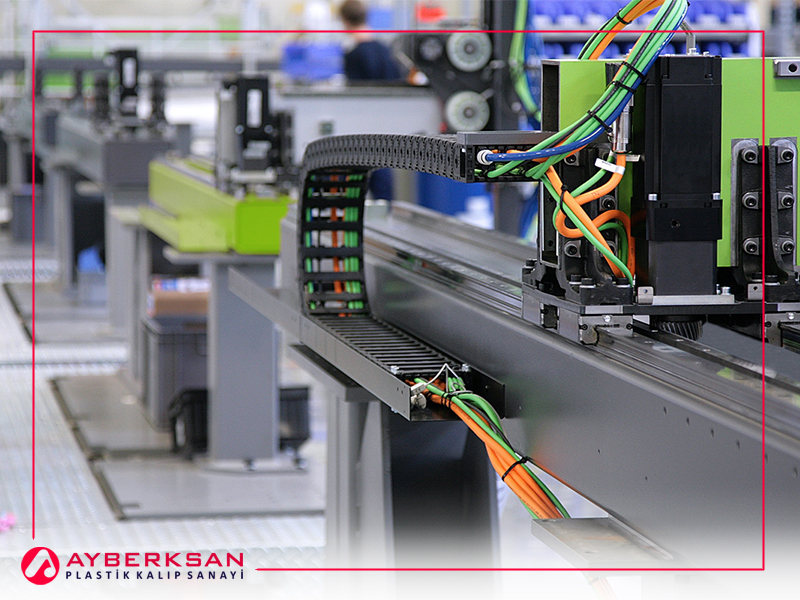

Plastic mold manufacturing allows you to produce products with a high precision ratio in a better quality and efficient way. Mold production is a process that allows mass production of all kinds of plastic devices, machine parts, disposable products used in the industrial field such as TV, automobile, pen, mobile phone, etc.

Mold production ca be made;

- Cold way injection mold

- Hot-way injection mold

- Blow molding mold

- Rubber press mold

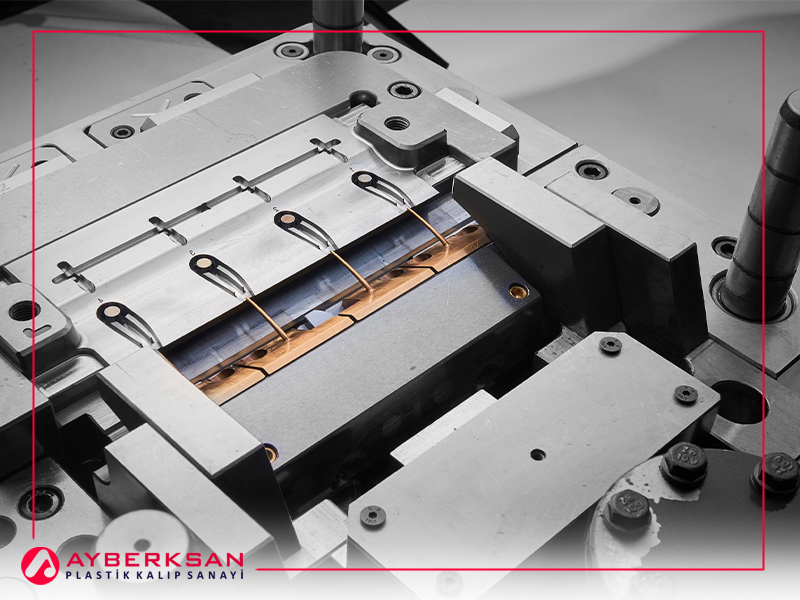

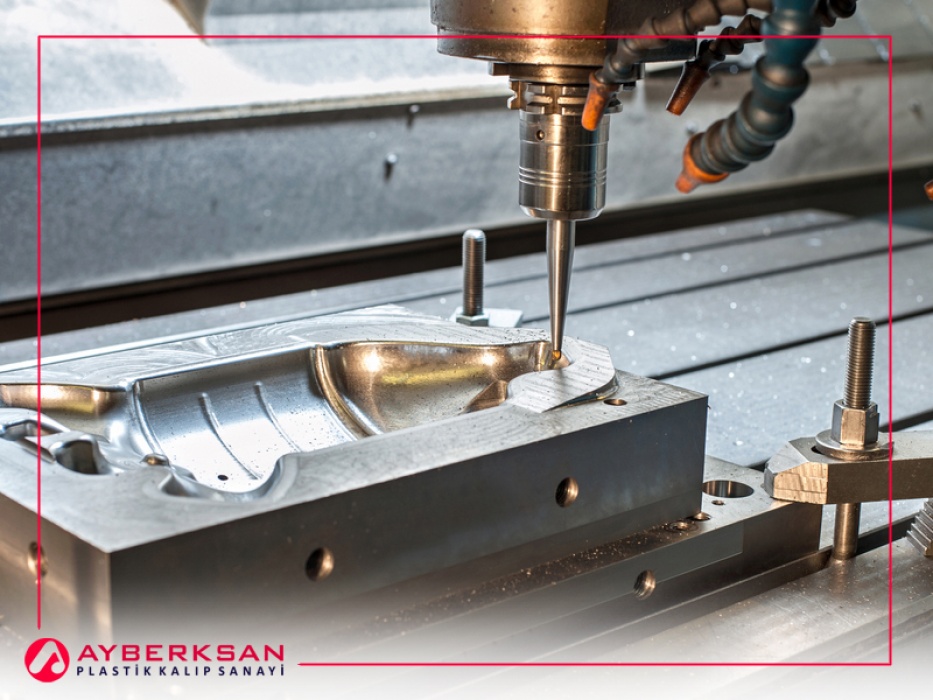

- Insert molding

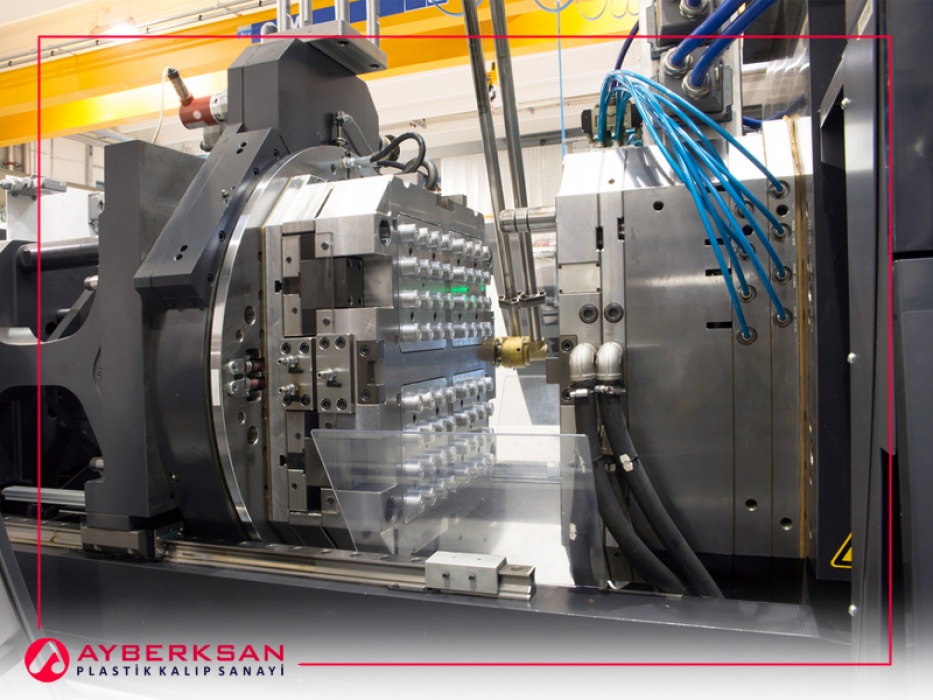

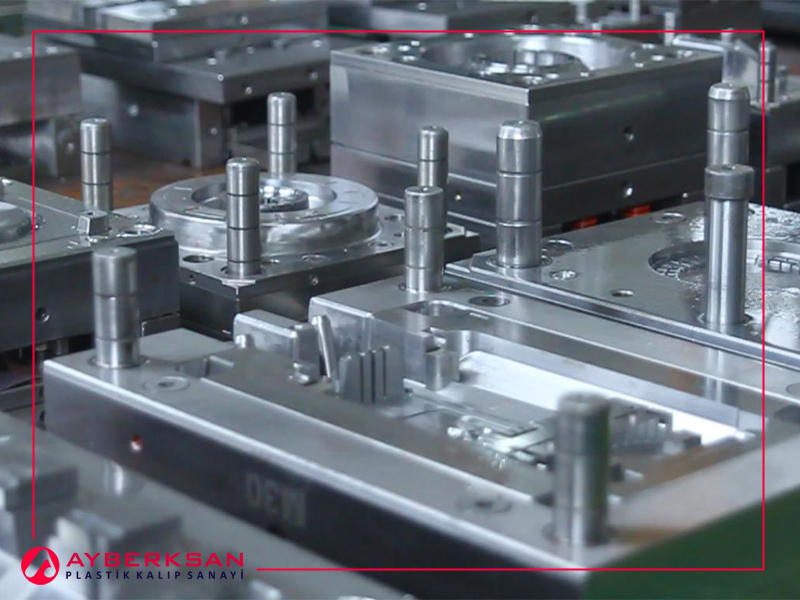

For processing the product on CNC machines, the designed mold must be programmed with GLASS. After the programming is done, the mold begins to be processed on CNC machines. In order to perform surface treatment; sand blasting, EDM immersion erosion, milling machines are preferred.

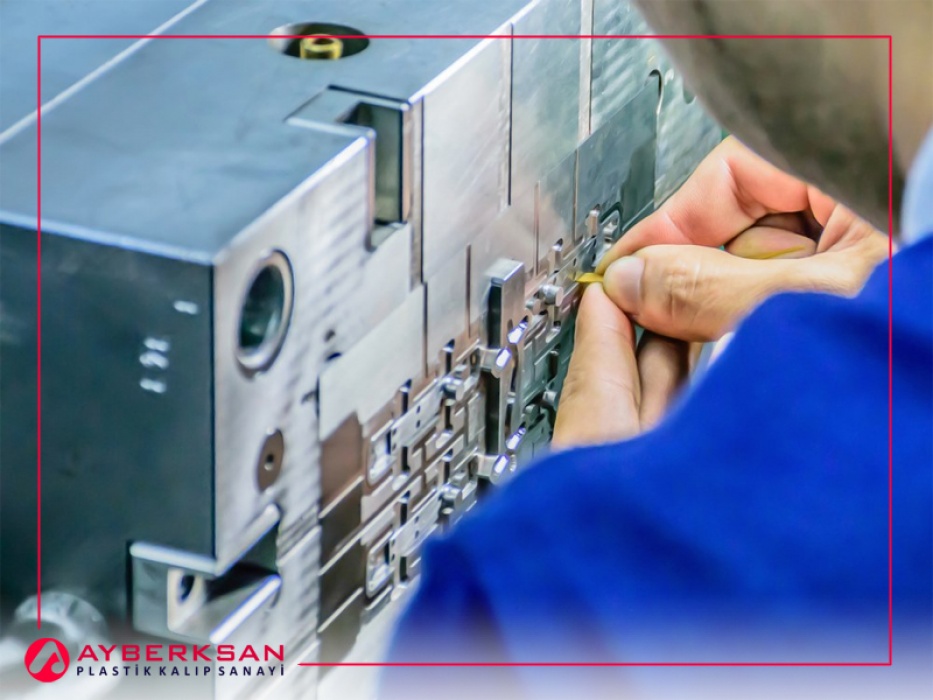

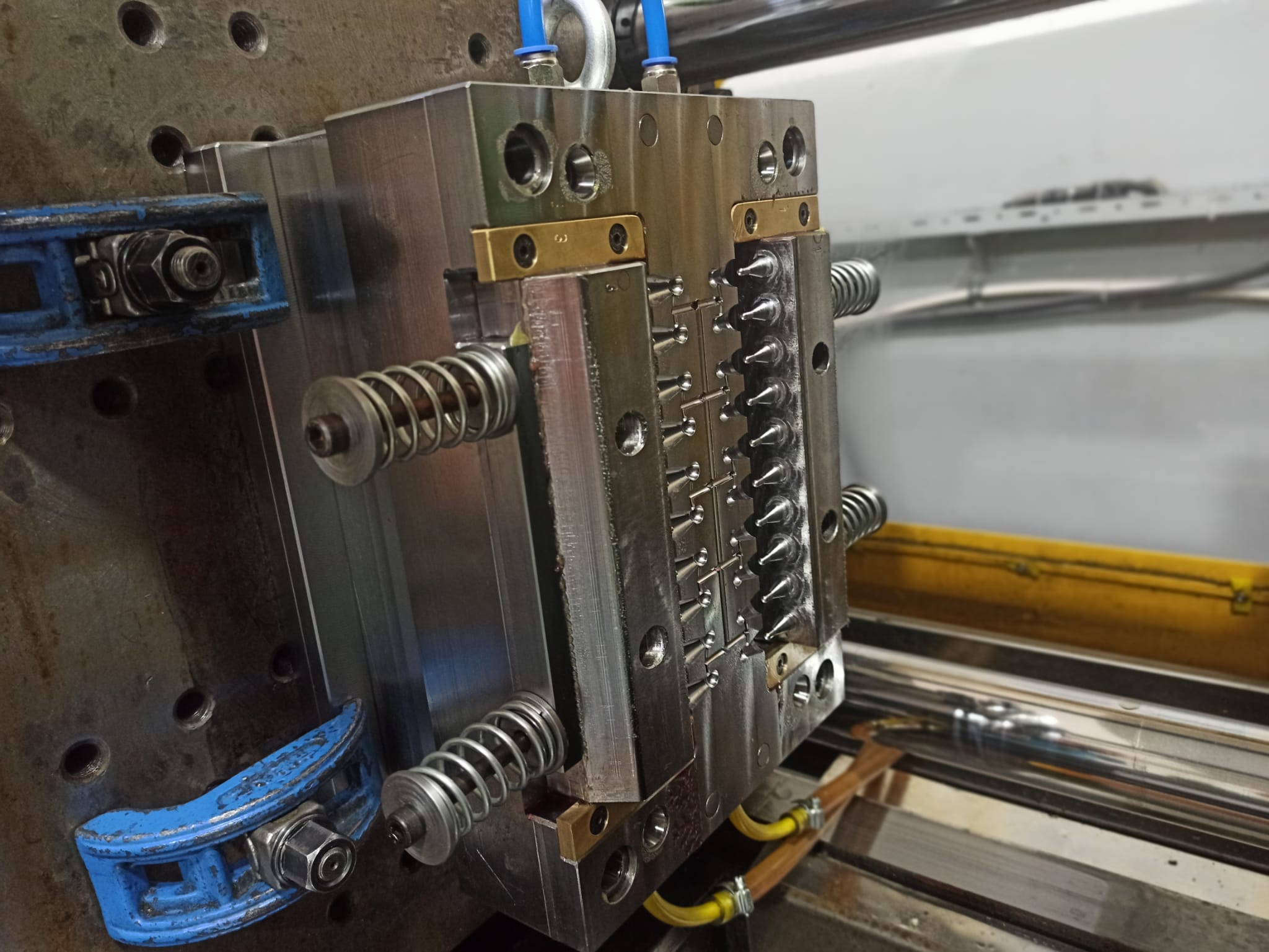

Before the injection mold is collected; the moving parts are checked once again and all inspections are performed. After the final checks, the mold recovers and goes to the trial edition.

Which Molds Are Used for Plastic Injection?

The plastic injection mold is made according to the purpose of use. In the manufacture of plastic molds, many different plastic injection molds are used.

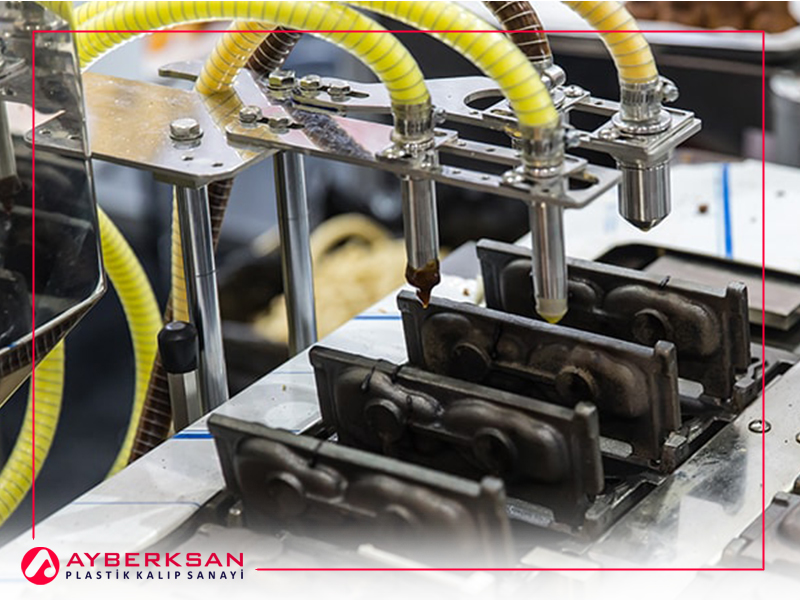

* Injection mold: These are molds obtained by melting thermosetting and composite plastics under high heat and pressure and injecting the product into the mold. It is widely used in the production of products in many industries, from the cover to the button, fasteners to device parts.

* Vacuum mold: This is the mold form used in the production of thermoformed plastics. It is a system applied by vacuuming the plastic plate as soon as it comes on the mold and taking the shape of the mold.

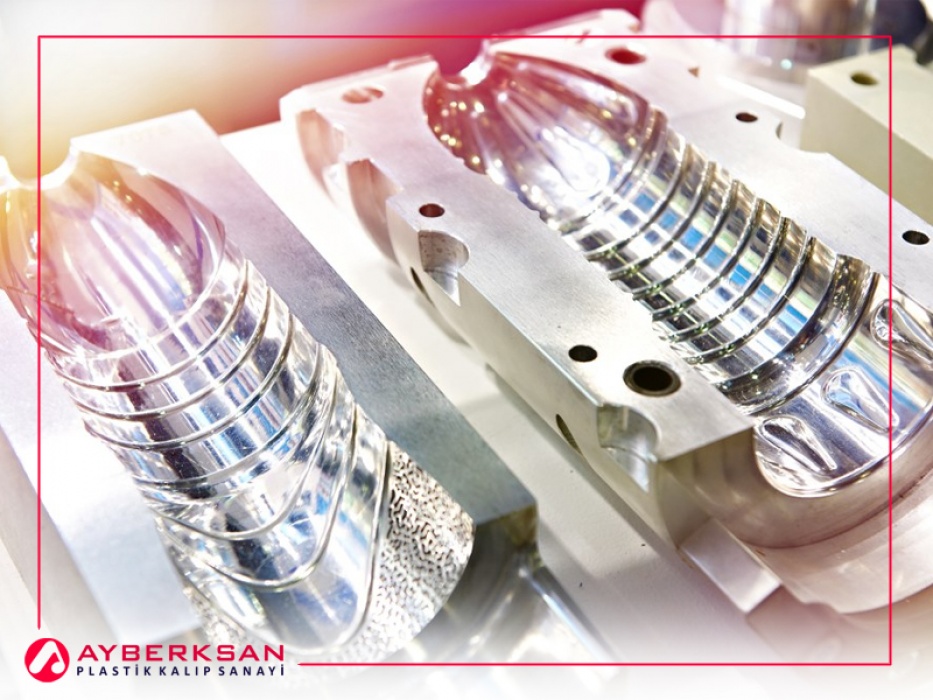

• Blow molds: Raw materials flowing through the january in a molten state are trapped in the mold and compressed air is supplied to form the product. Canisters, bottle molds are examples of these.

• Extrusion mold: It is made by cooling the product melted in the extrusion january with air or water by continuously flowing in the plastic mold. Window-door profiles, cables are produced in this way.

Offering you years of experience with innovative solutions https://ayberksan.com by visiting the website/, you can get the professional consultation you need and see our designs.