Plastic Injection

The use of plastic injection is an application that has increased recently. It is the process of injecting the melted plastic material into the mold and obtaining the product because of the raw material that cools down after the injection mold is closed. Plastic products produced by plastic injection are preferred in many areas. Plastic injection is a method that is always preferred. Care should be taken to ensure that the plastic molds used during the plastic injection process are long-lasting and of good quality.

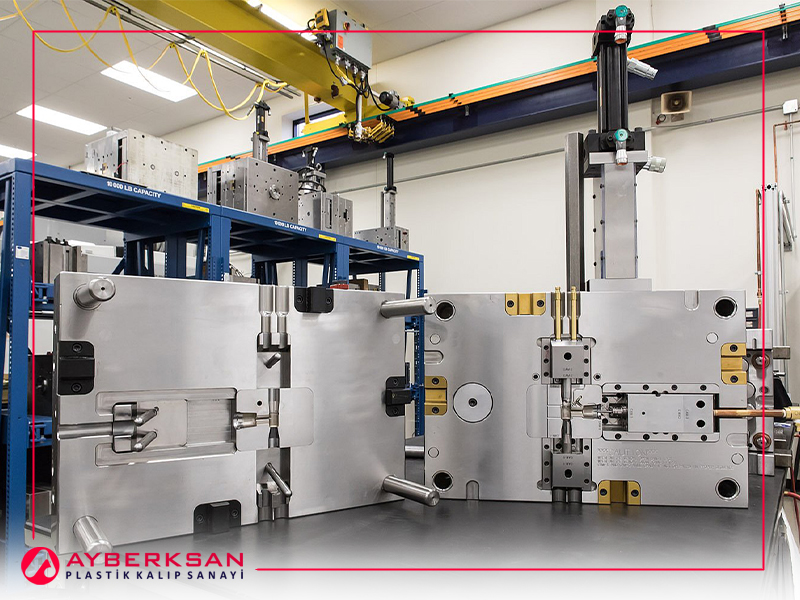

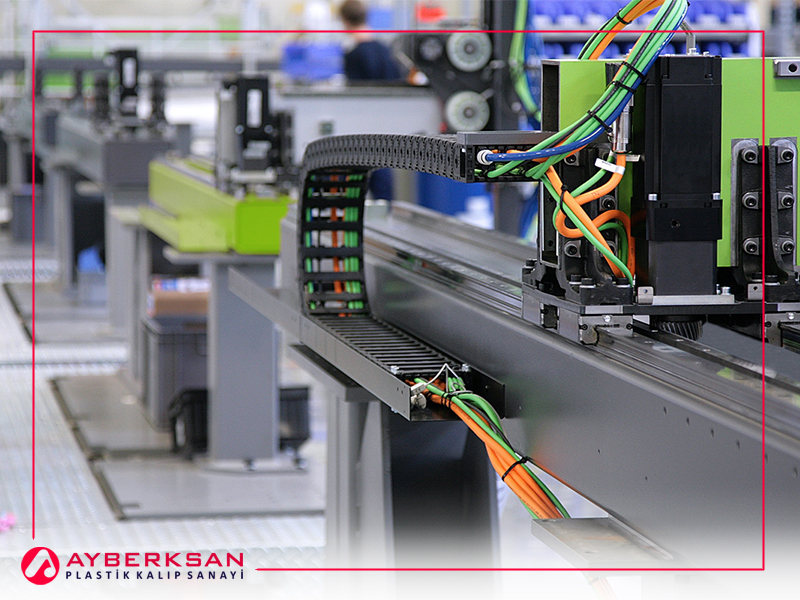

What is Plastic Injection Molding Machine?

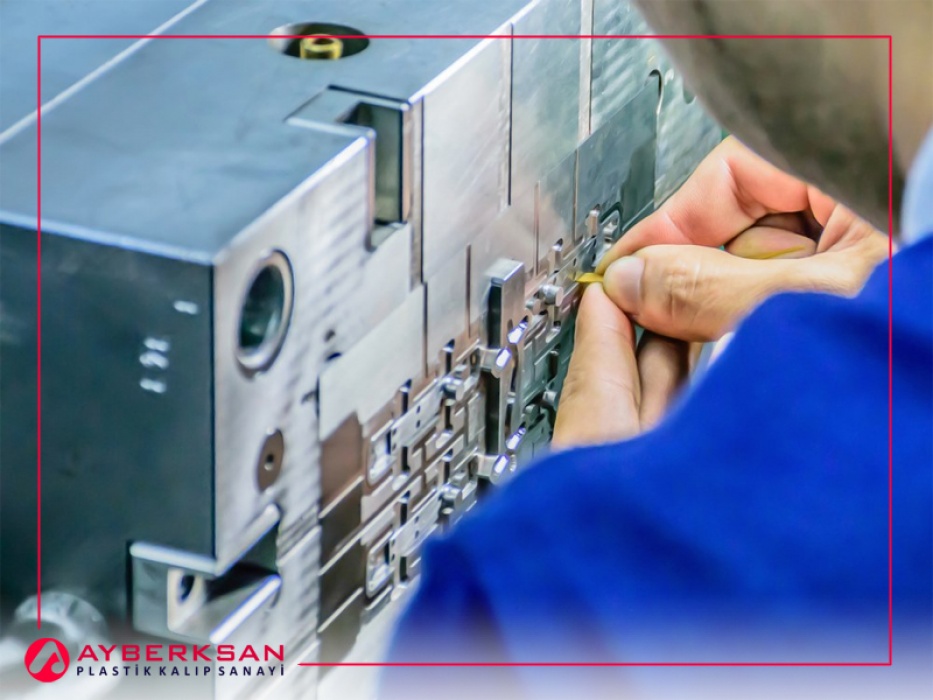

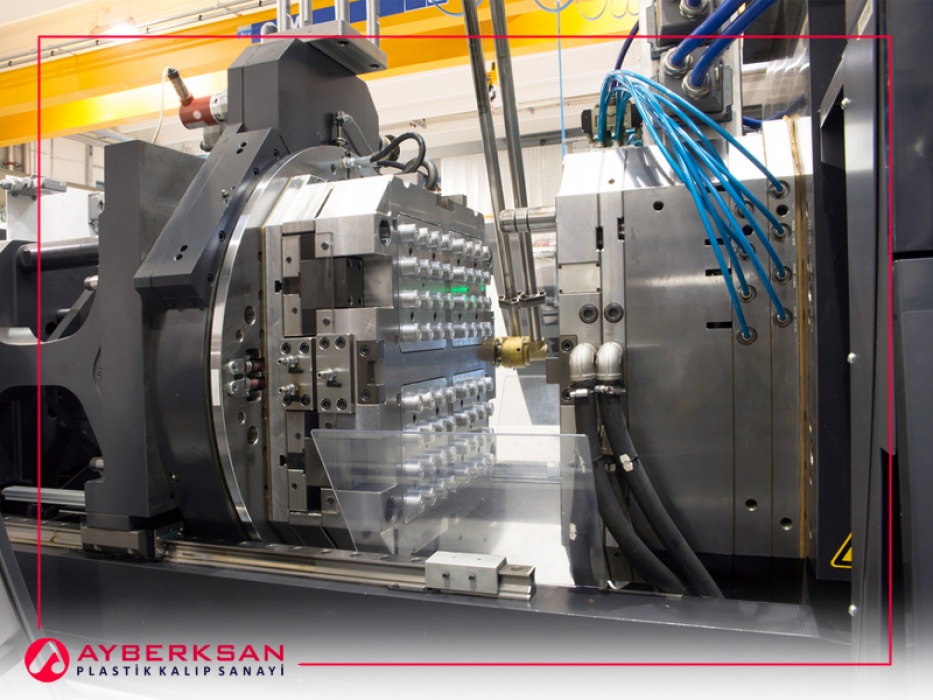

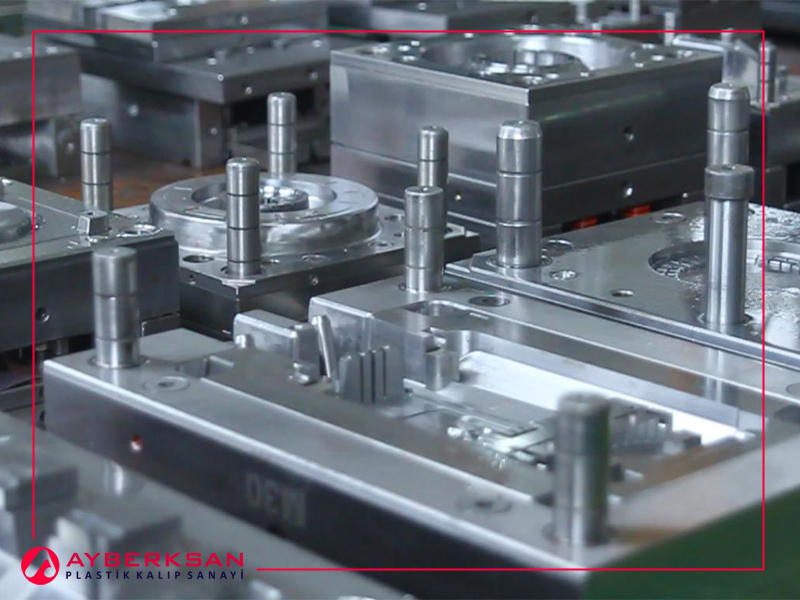

It is a special machine in which plastic manufacturing and molding are done easily. In the machine used as an injection press, a plastic product is obtained because of the cooling of the hot raw material injected into the injection mold. There are two parts to the machine. These are the vice and the mold unit. In general, the plastic injection machine provides production in horizontal and vertical positions while producing plastic products. Today's machines are located horizontally. Machines used in horizontal positions are not used under high pressure. Vertical machines are generally preferred under high pressure. Fixing the plastic injection mold inside the machine should be done carefully.

How Does a Plastic Injection Molding Machine Work?

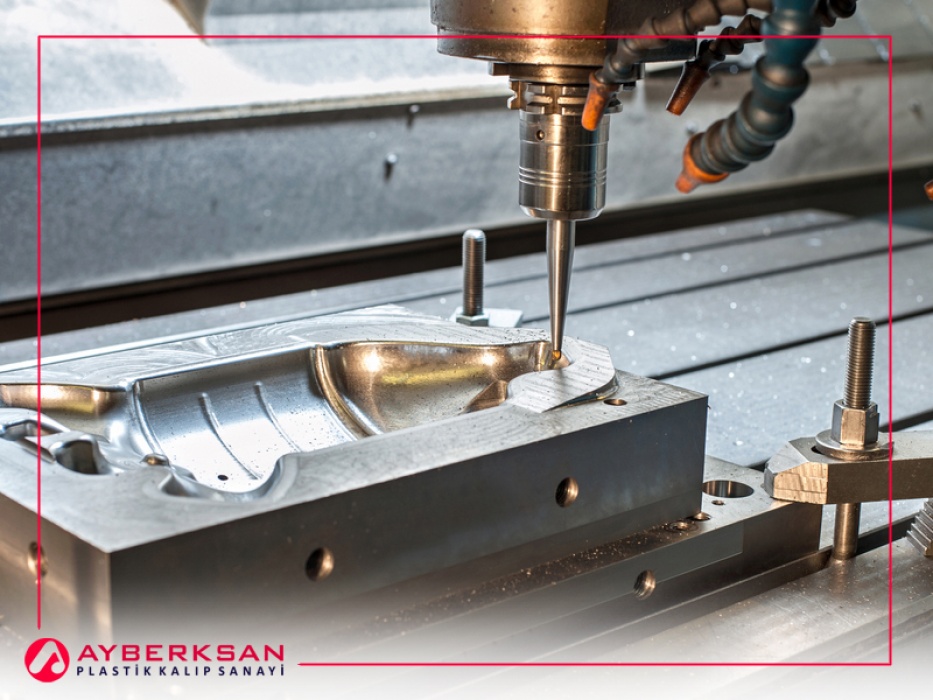

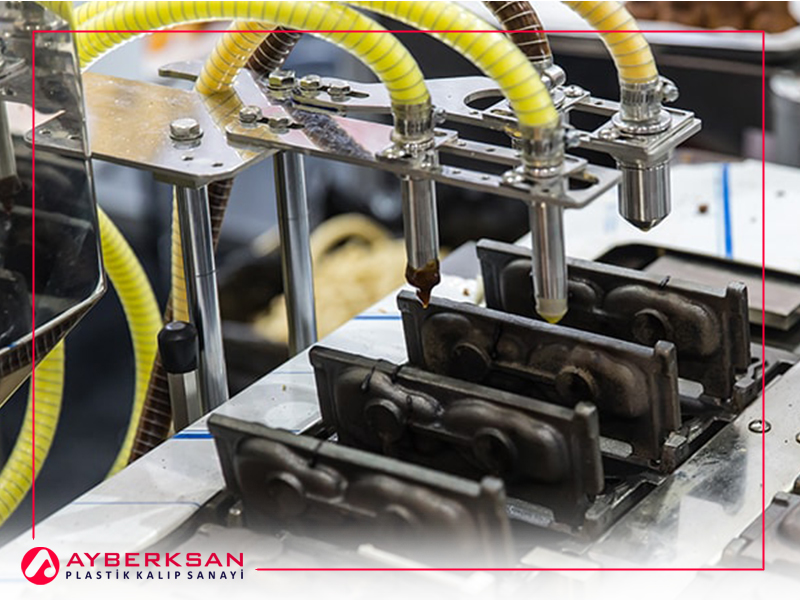

The plastic injection machine is very important for the formation of plastic raw material. The cooled plastic product will be removed from the mold, which helps to form the plastic product. Plastic injection molding machine produces plastic by injection method. Production takes place by injecting the molten raw material into the mold, closing the plastic mold, and cooling the plastic.

What is Plastic Injection Molding Method?

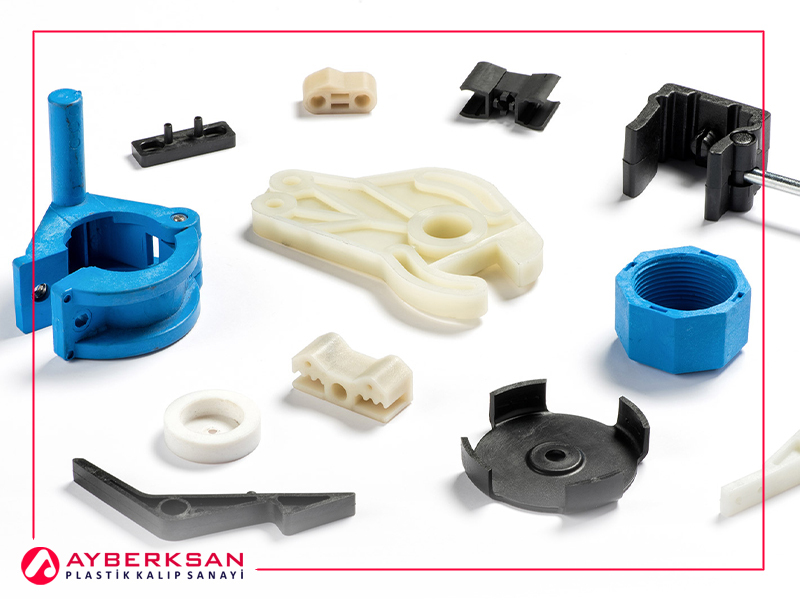

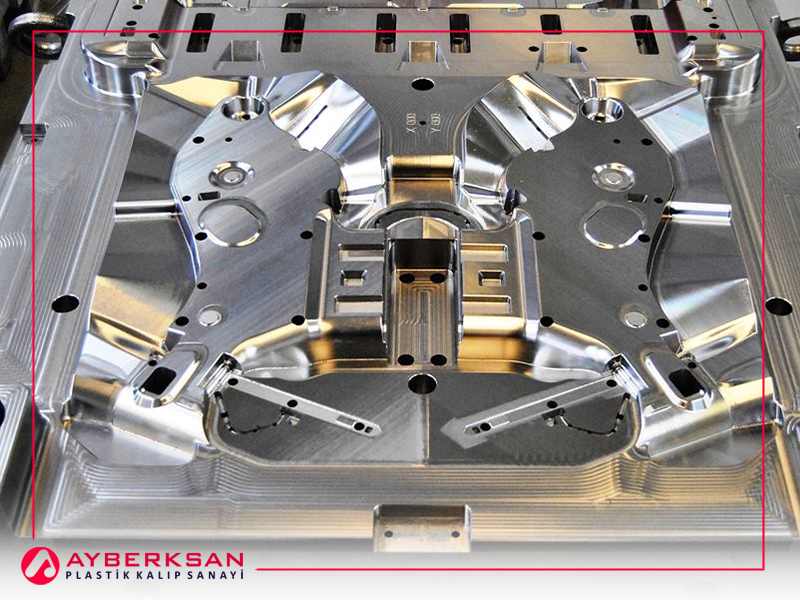

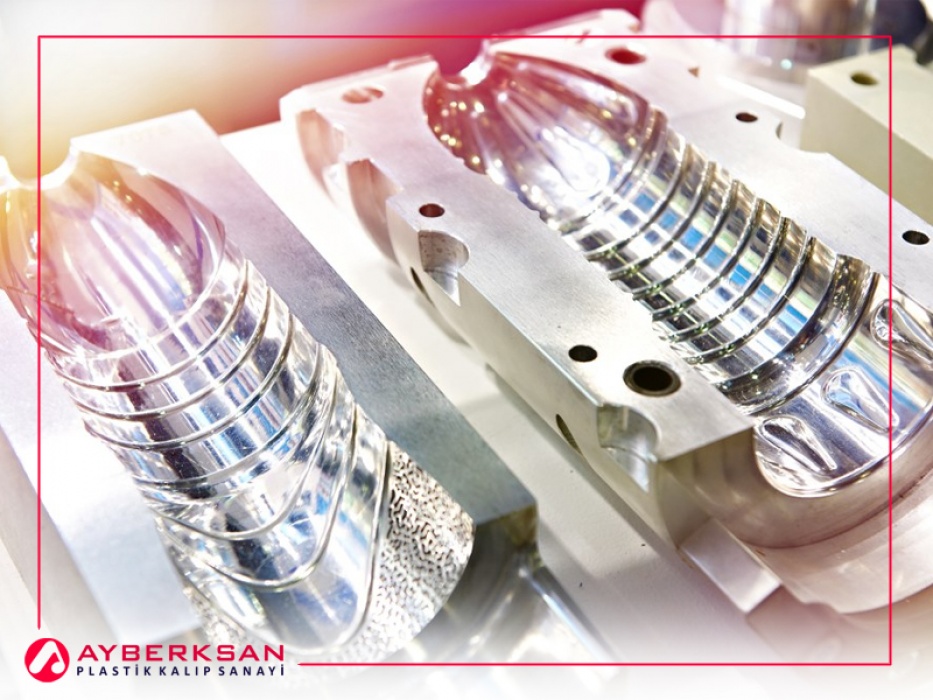

The injection molding method is a very advantageous method. The plastic injection method, which offers mass production, provides many advantages. While injecting, the polymer-containing substance is melted. After melting, a certain pressure is applied. It is expected to cool down after pressure. In general, different coloring agents are preferred in the plastic injection system. Today, many plastic parts are produced with plastic injection molds. Plastic injection system also provides convenience in many aspects of our daily life. Injection mold production takes approximately 4 weeks. Cost and prices also vary according to the product geometry and the length of the production period.

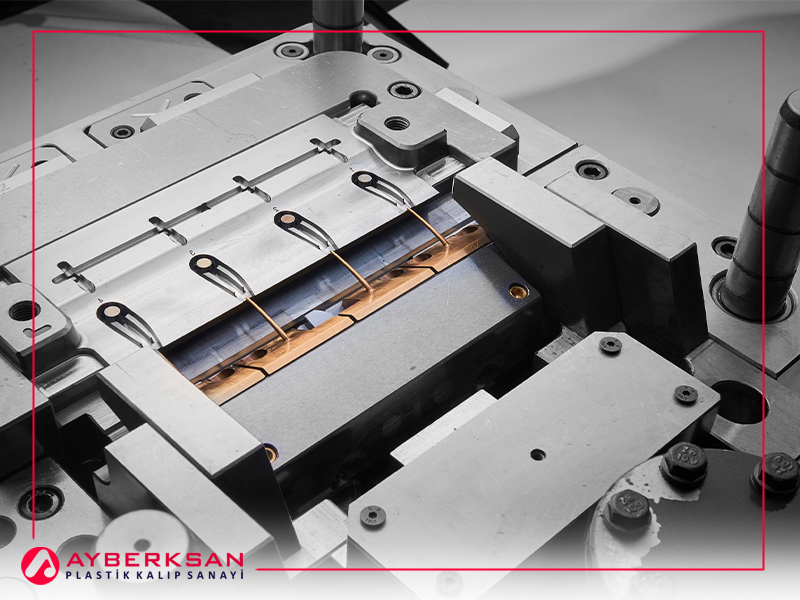

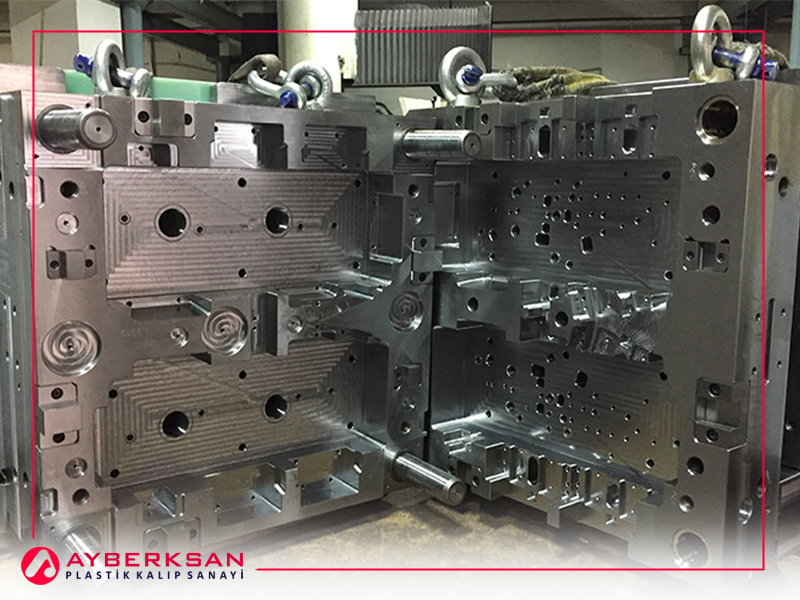

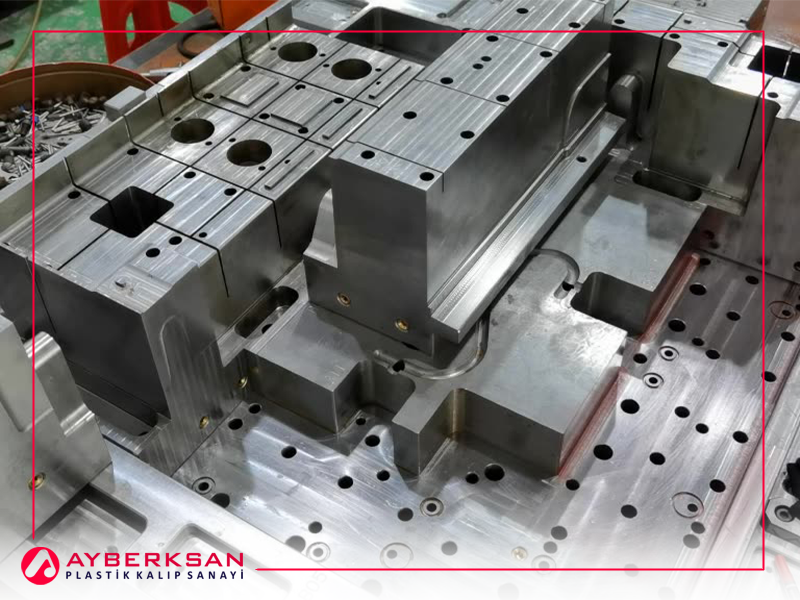

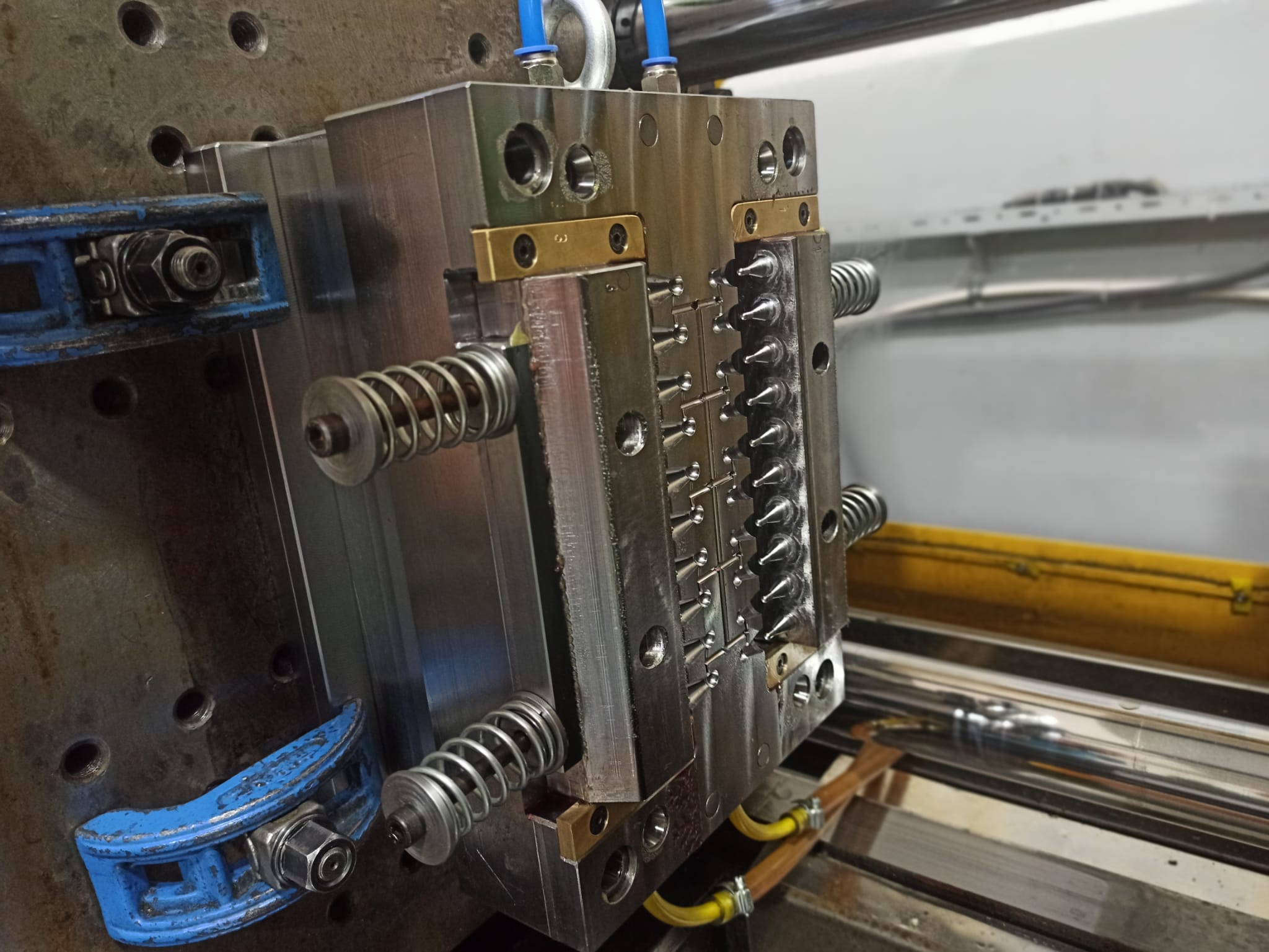

How is Injection Molding Made?

Plastic molds, which are generally preferred to produce many plastics, are very important. The structure of the material is very important when installing the injection molding system. The surface area and structure of the material used for the mold are of great importance in molding. Molding provides many advantages. Injection processes benefit mass production. Injection molds that provide high production provide a time advantage. During the production of plastic molds, necessary studies are carried out to ensure that the produced parts are suitable for mass production. Although the cost of injection molding seems quite high at the beginning, considering the time to be obtained from mass production and high production volume, plastic injection mold amortizes its cost in a short time. The molds produced must be resistant to 1,000,000 presses. Injection molding, which appeals to a wide range of products, provides many advantages. It is a special product with different physical properties. Mold manufacturing, which offers high efficiency, is very important. At the end of mass production, molds that are constantly opened and closed may cause wear if maintenance is not performed. To obtain a visually wonderful and flawless appearance, the molds should be maintained periodically.