Plastic Injection Molding

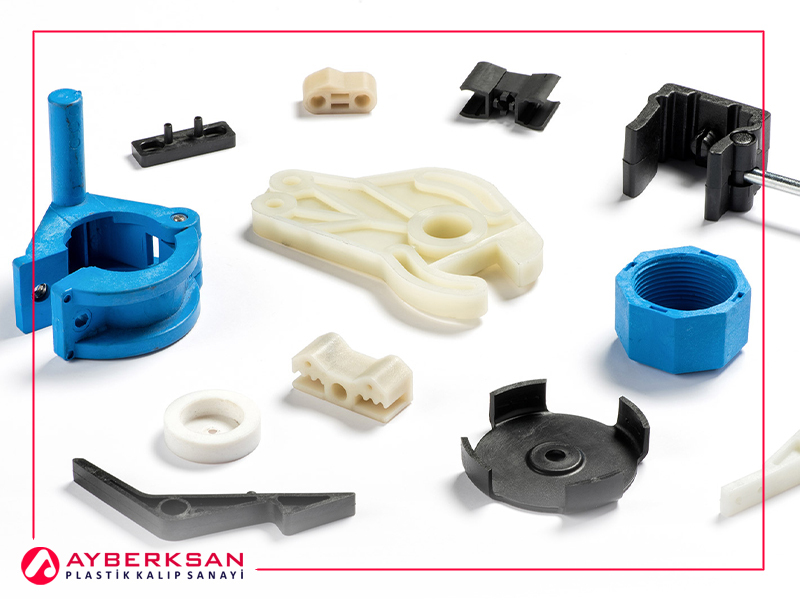

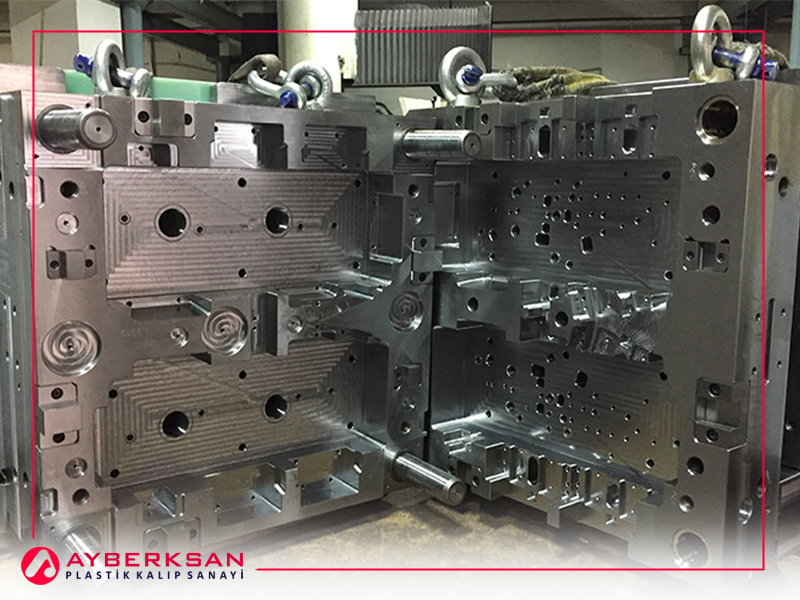

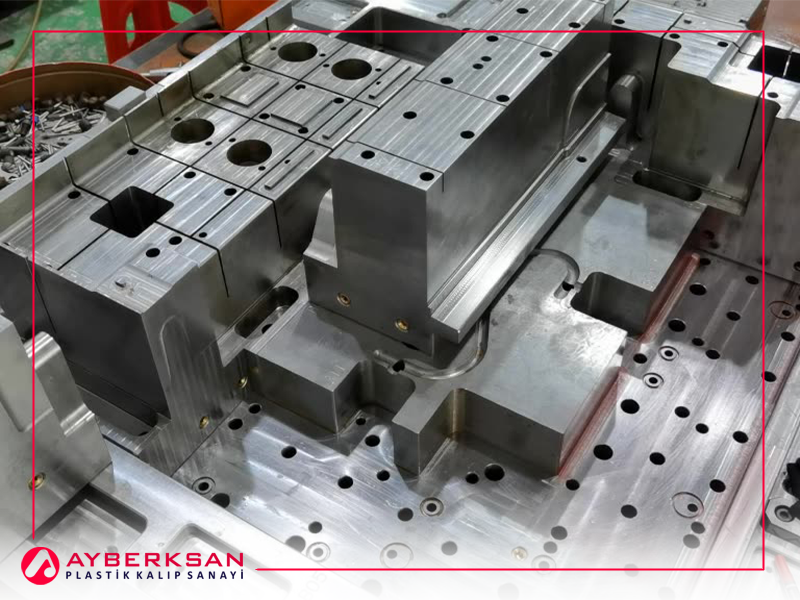

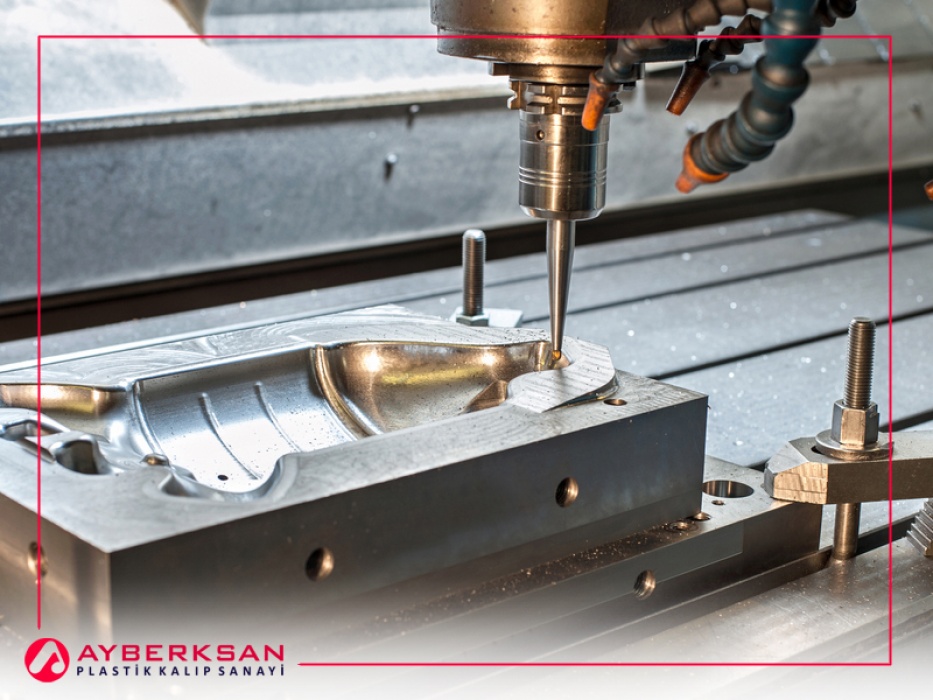

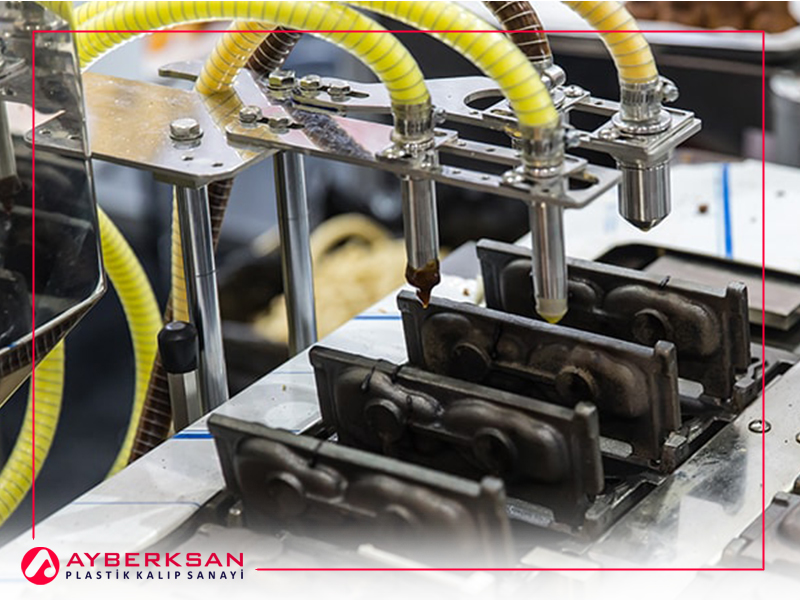

Plastic injection molding is a special application as it is used with melted plastic raw materials. Therefore, plastic injection molding designs are used in many areas. It is generally preferred especially in industrial production. It is an indispensable part of injection molding machines. The machine is mainly composed of vise, injection, and mold. The raw materials put into the machine are heated at a suitable temperature. After heating, the raw materials are melted. An error occurs if monitoring is not performed during the injection molding process. The plastic production process proceeds successfully with regular maintenance and the right choice of raw materials.

Plastic Injection Molding near by

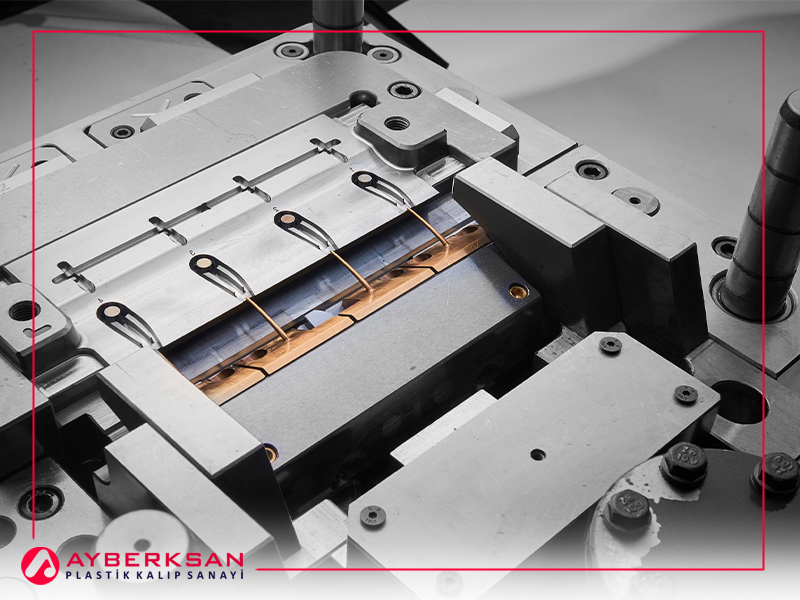

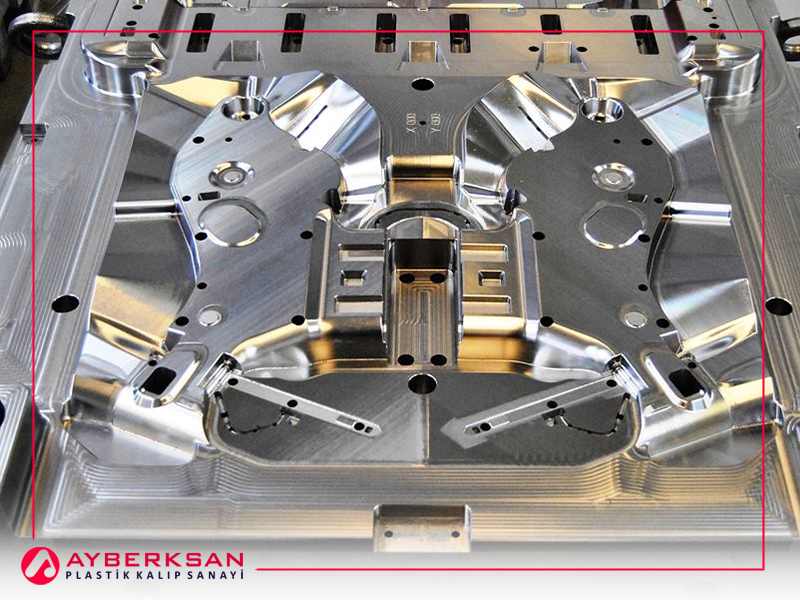

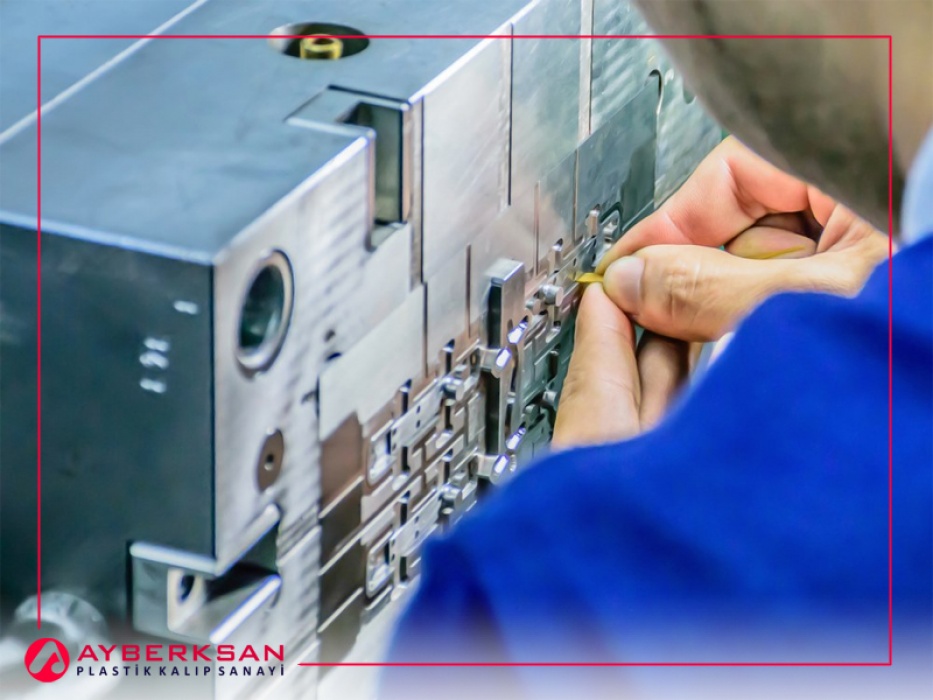

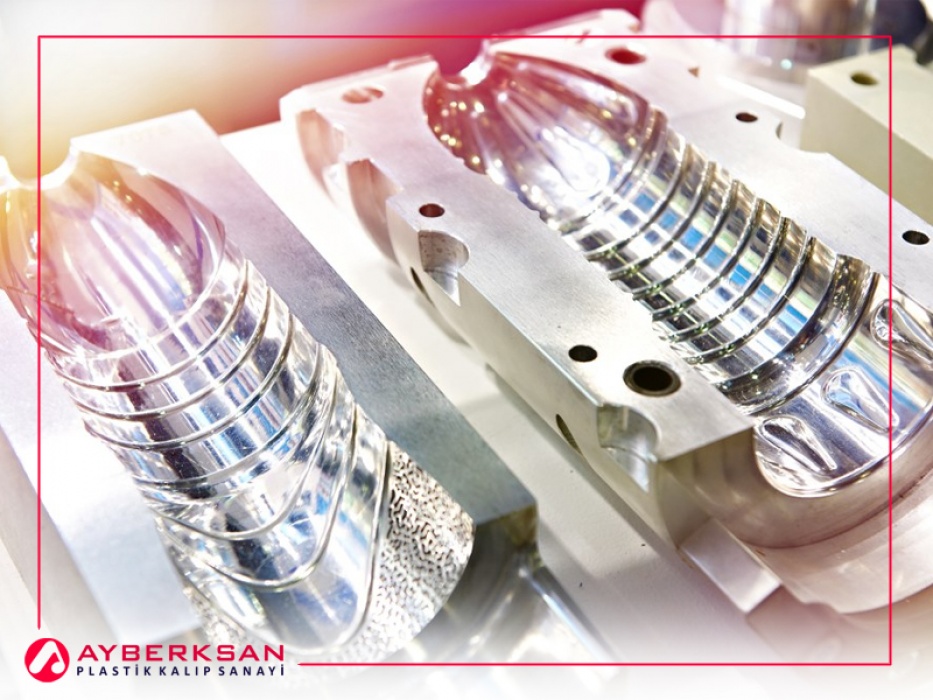

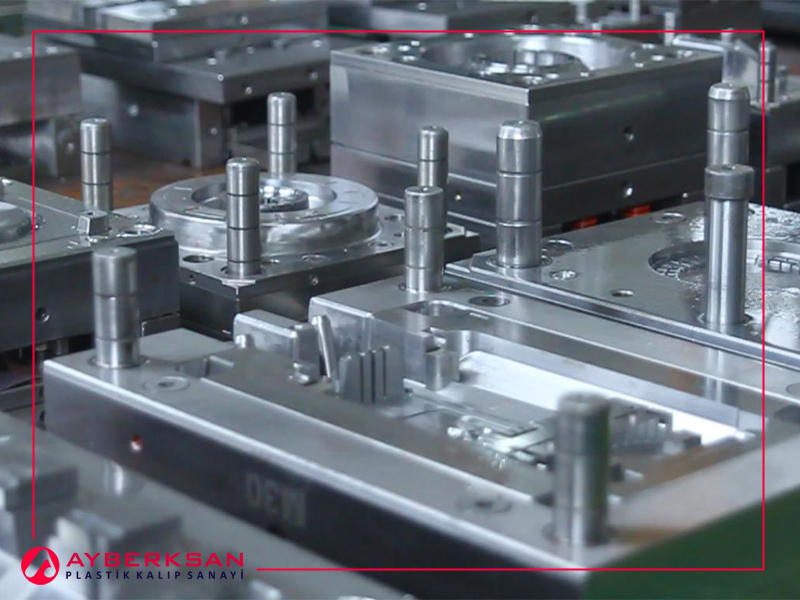

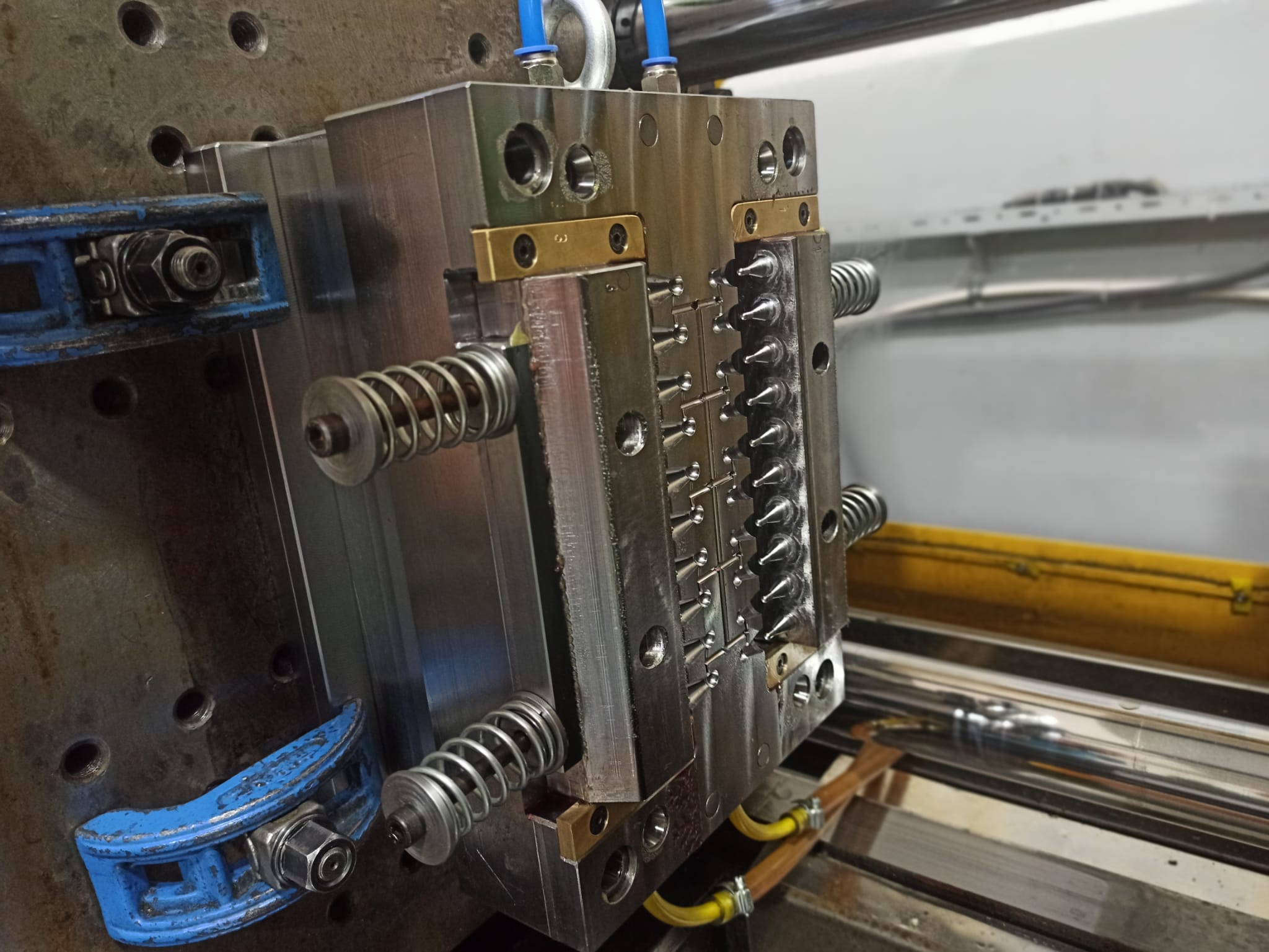

An injection molding machine is a process in which plastic raw materials that melt at a certain temperature are put into an injection mold under a certain pressure, and the mold is opened after the relevant cooling time expires and the plastic product is output. In order to benefit from this process, it is possible to take advantage of the plastic injection molding option near by. Although plastic products are generally obtained by pouring molten plastic into a mold, great care must be taken at every stage in order to complete the plastic injection molding process perfectly. It should be ensured that the raw materials used in plastic injection molding are free from moisture and dust, regular maintenance of the molds should be done and precautions should be taken against operator errors. In addition, regular inspection and maintenance of the funnel, screw, nozzle, runner bushes, and barrel of the injection machine are important.

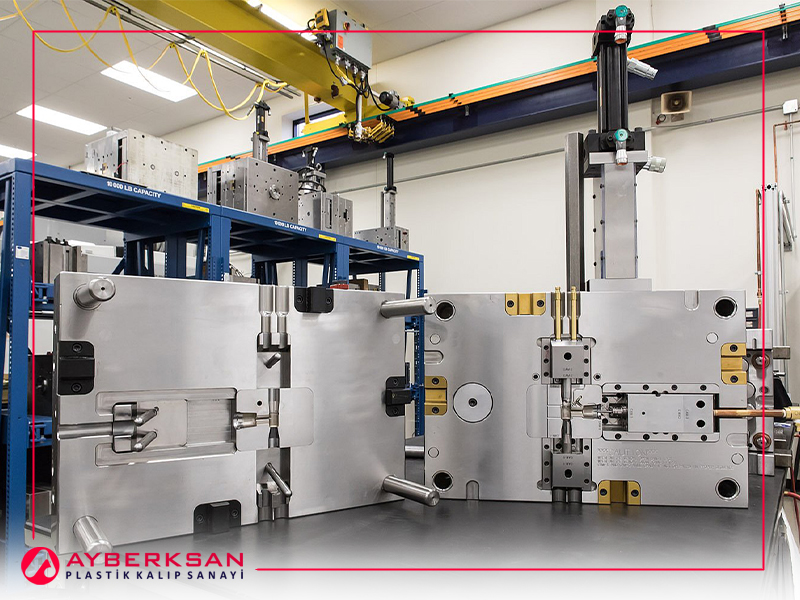

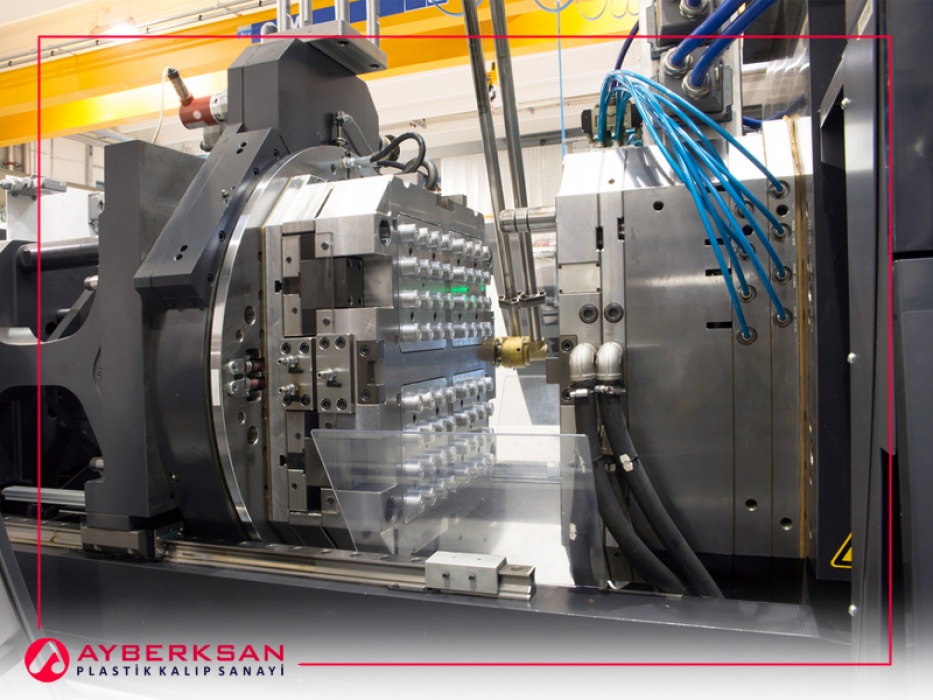

Plastic Injection Molding Machine

Plastic is delivered from the plastic factory by melting and reshaping. The cooled material is then finalized by molding. The material is produced by plastic injection molding. It is mainly used for plastic molds of injection molding machines. The plastic injection machine consists of 3 parts. Injection unit and mold part of the machine. At the same time, the compression device will be from the machine. Plastic injection molding, the clamping device is the first choice. It is very important for the shutdown device. It is a mechanical part used to protect certain equipment. It is the fit part of the injection mold. Injection units are called the place where it is poured. This part of the construction section has plastic furniture. It is designed to be melted into a high-end model. Use in the mold until the plastic material is formed from solid material in the molding process. solid can be formed and the mold is formed by removing the plastic.