Plastic Mold Manufacturing

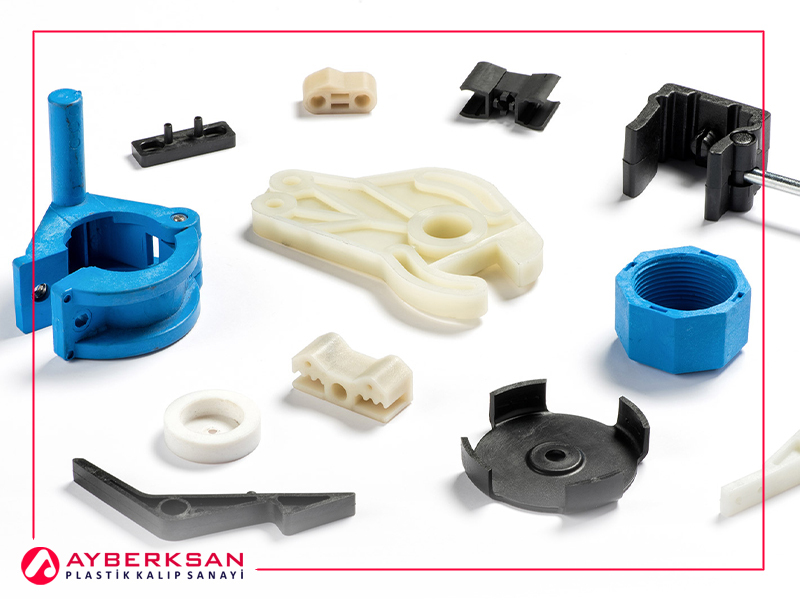

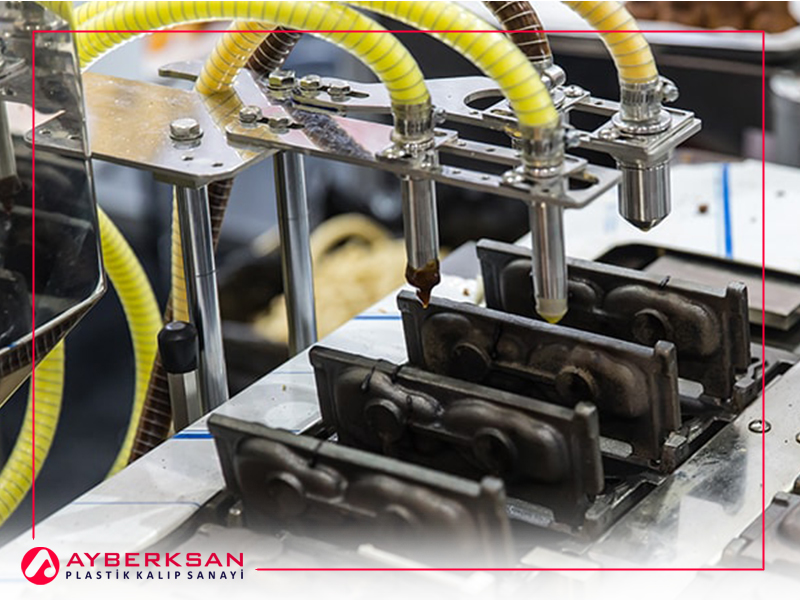

Plastic injection mold manufacturing provides convenience in the mass production of plastic in the market. The mold manufacturing industry is very popular. The mold can be defined as the assembly of the determined parts based on human power with the help of the machine to form the template of the desired product. Plastic molding is among the activities that are increasing day by day. Timing is very important in plastic injection mold production.

The measurement is taken in mold manufacturing also provides a great advantage for production. Today, we see plastic products almost everywhere around us, thanks to the widespread use of plastic molding.

Plastic Mold Advantages

Especially plastic injection molds that allow mass production offer advantages in the long run. Thanks to being made of special steel, it offers the opportunity to obtain a lot of products with a little maintenance. Thanks to the plastic products that are in demand in every sector, plastic injection molds have become indispensable today.

Plastic Mold Disadvantages

The disadvantages of the plastic injection mold first appear with the costs. The cost of benches and equipment used to produce plastic molds, which can take up to 4 weeks, is expensive and requires qualified labor. Another disadvantage is that the plastic mold production time is long in cases where urgent production is required.

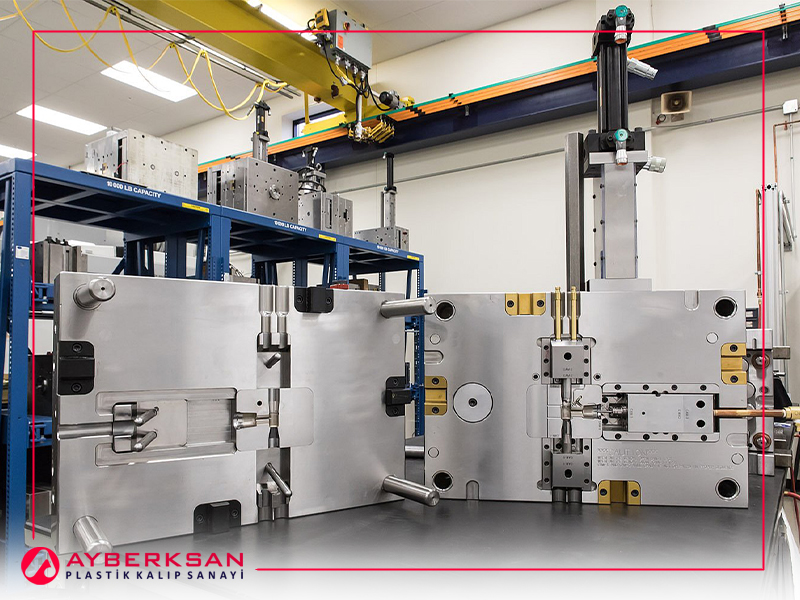

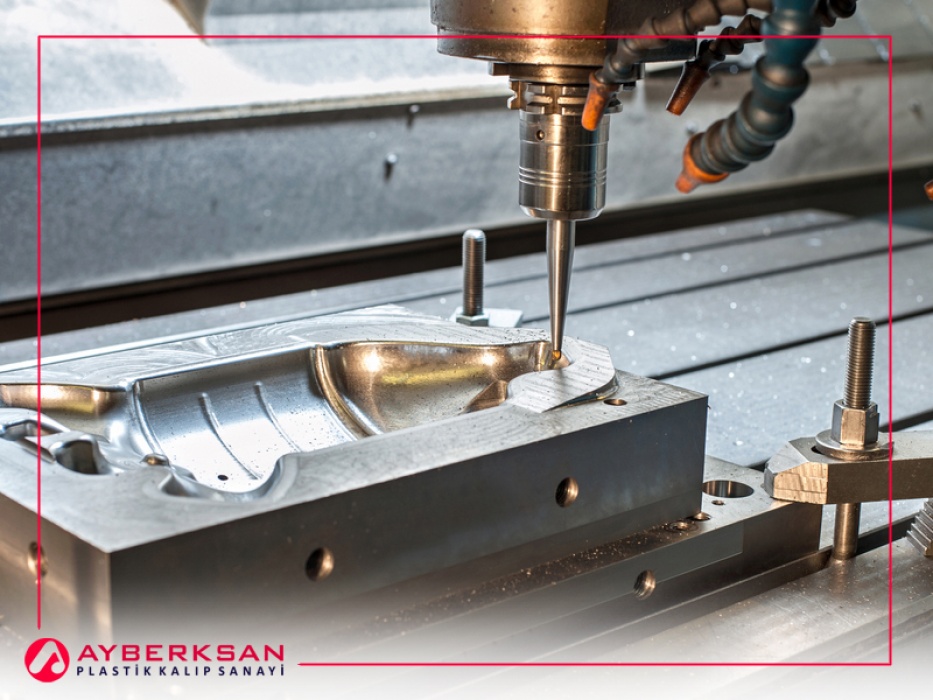

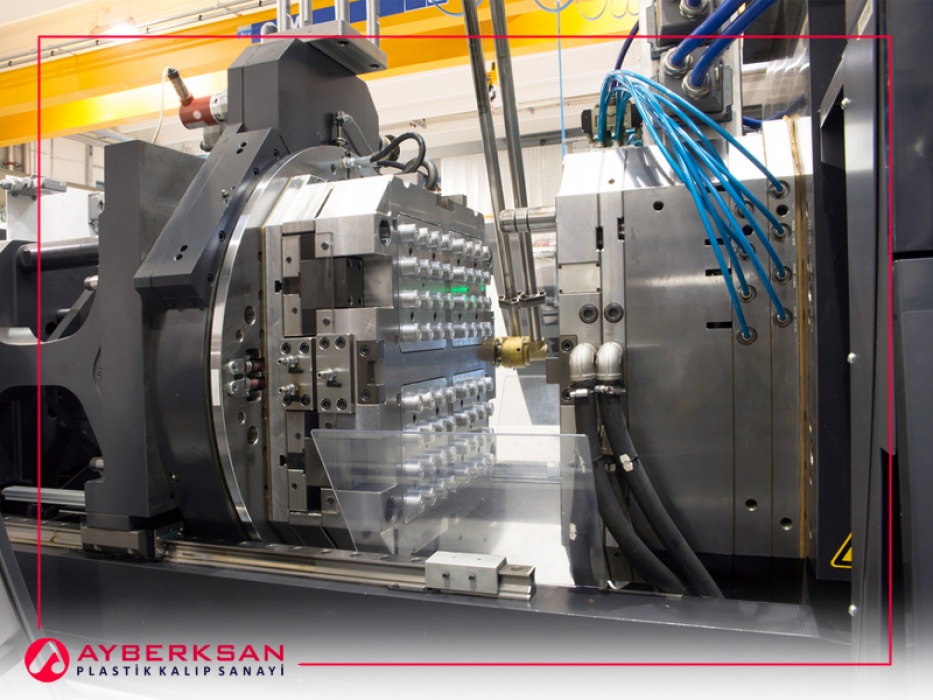

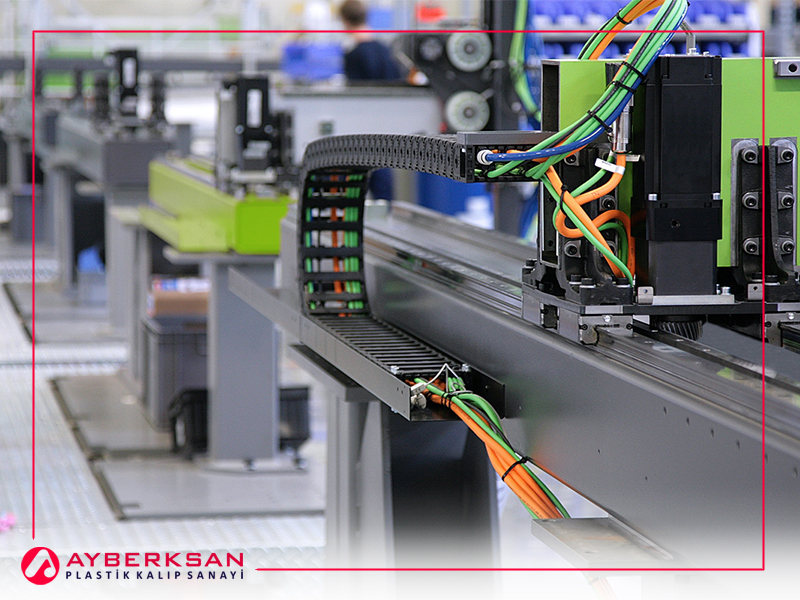

Machine Used in Mold Manufacturing

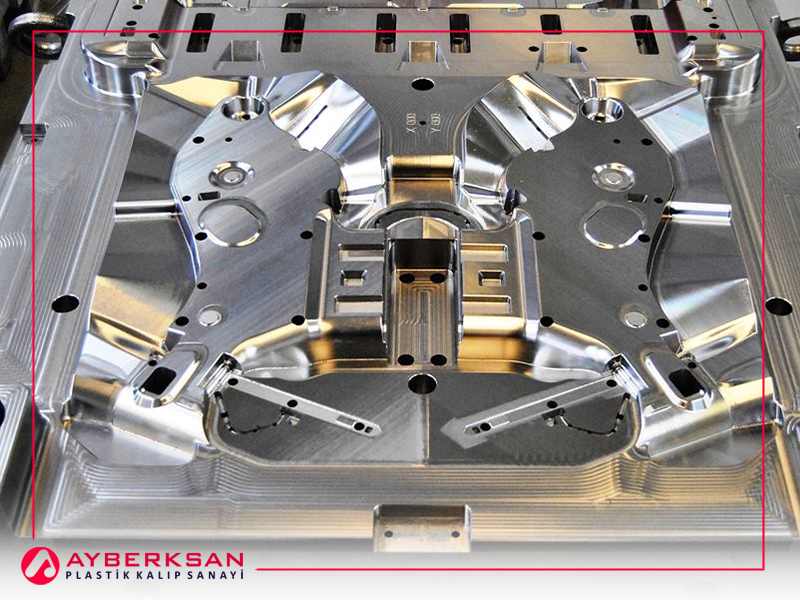

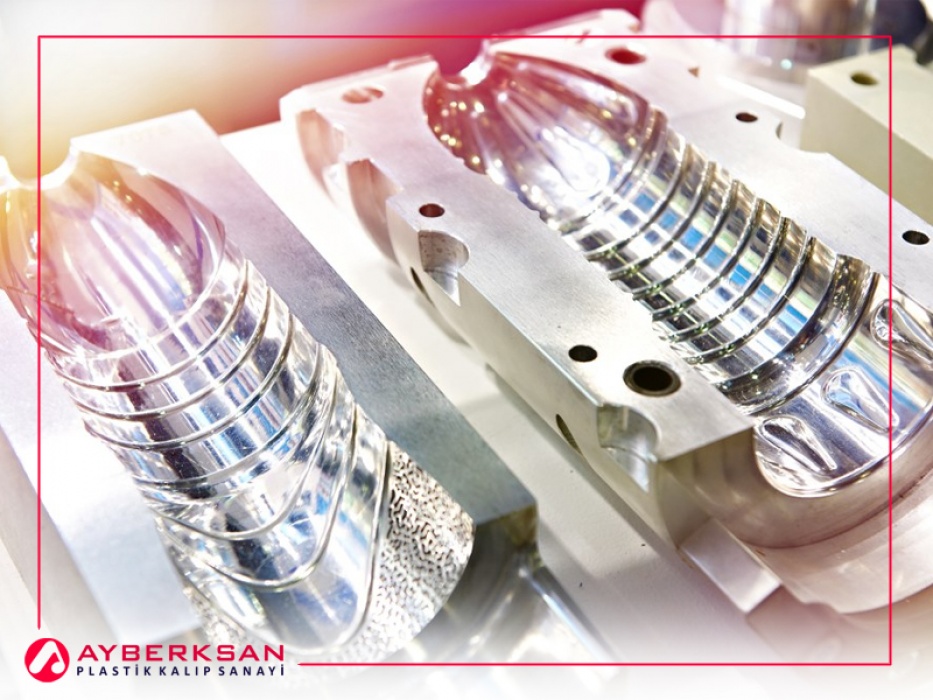

CNC, lathe, milling, plunge erosion, etc. in plastic mold manufacturing processes. machines are preferred. Before the molds are made, the designs are obtained. It is suitable to use the Cad program for their designs. Molds are designed in a computer environment, CAD, CAM, etc. for related machines. It is programmed, then it is combined to appear. The size and shape of the product are very important when manufacturing molds. Plastic mold elements also vary according to the product and the size of the mold.

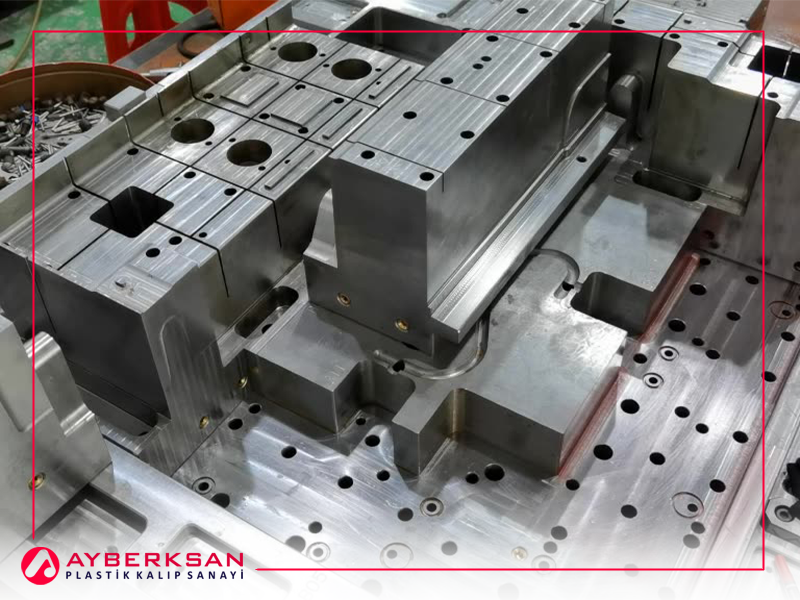

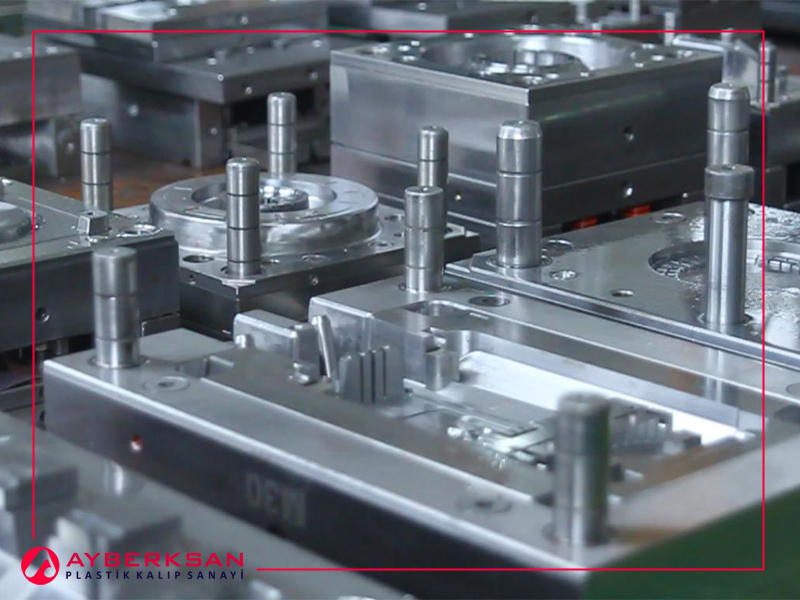

Elements Used in Mold Manufacturing

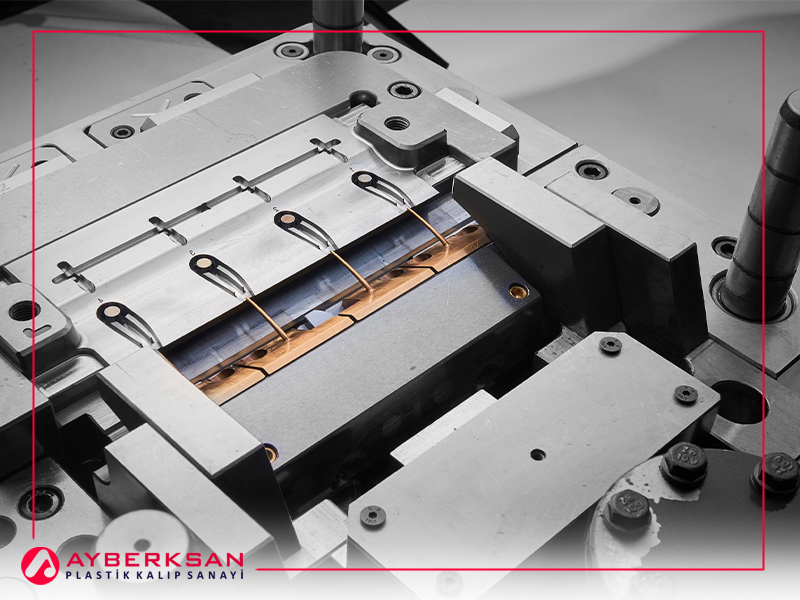

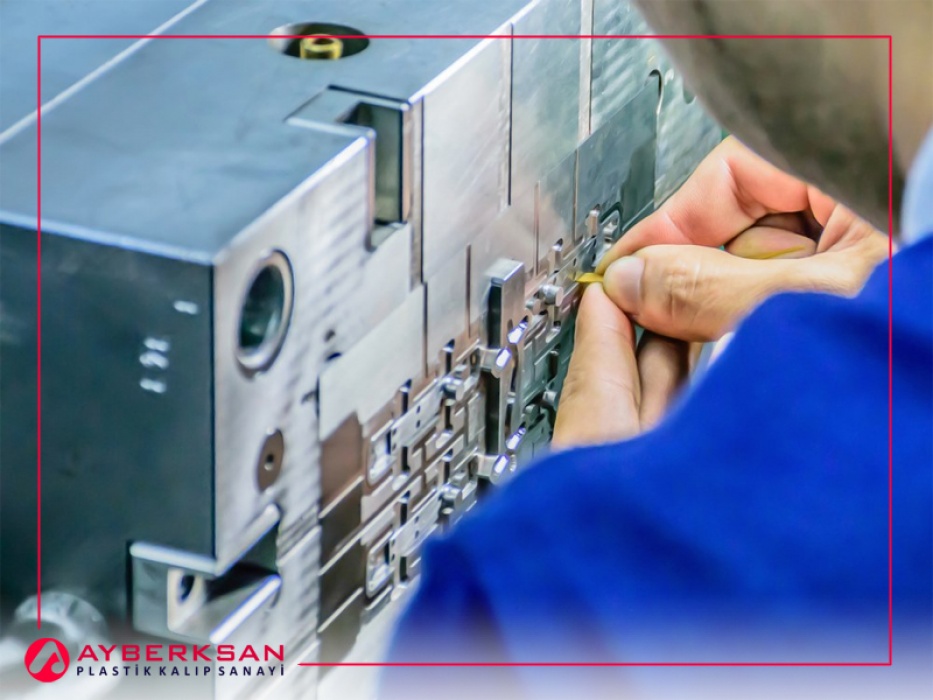

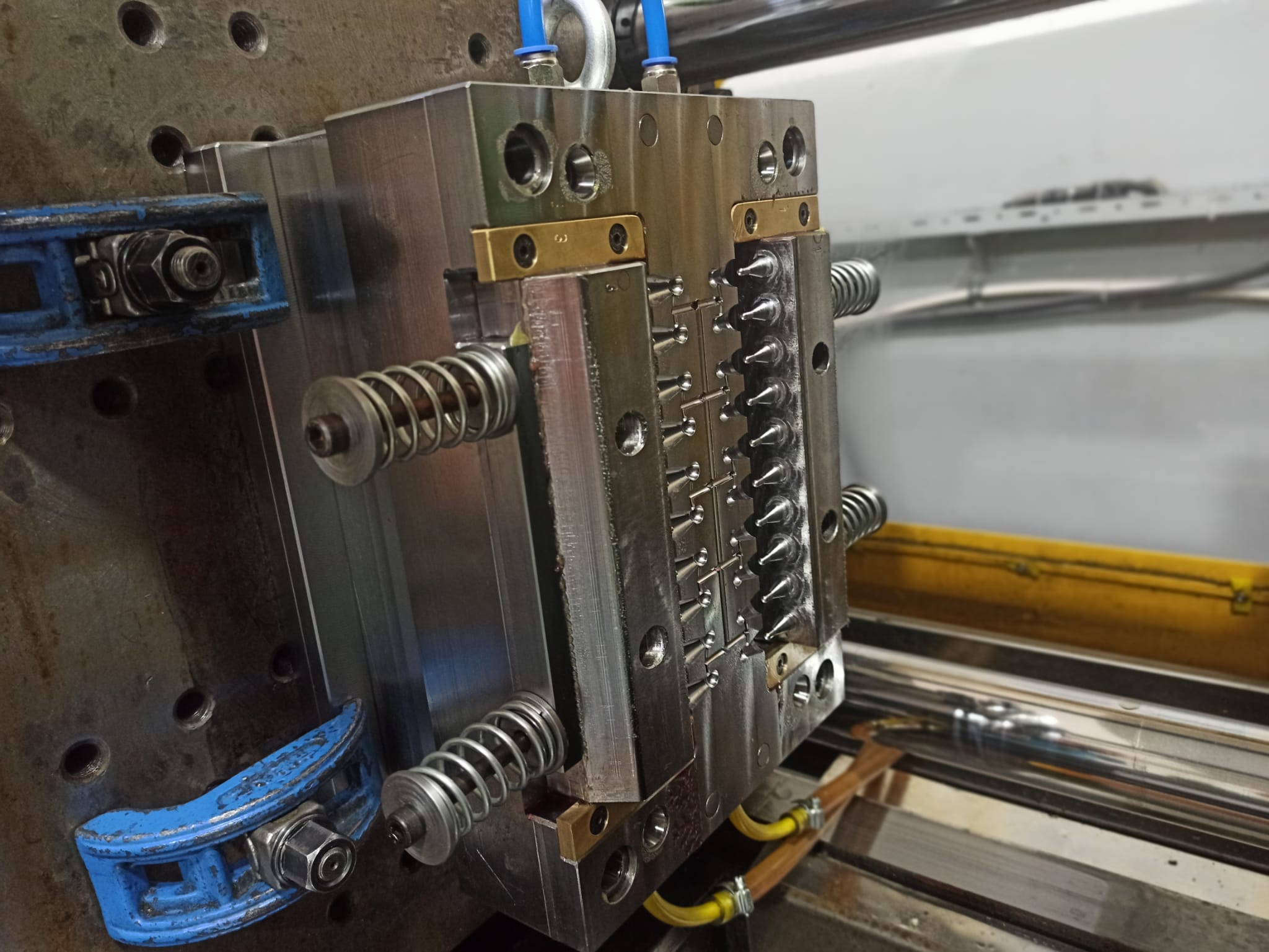

In-mold manufacturing, runner bushing should be used. Thanks to the runner used here, the material used in mold manufacturing passes easily. Also known as ready-made mold elements. The flash, that is, the centering pins, is very important in making the molds open and close. Pin parts are placed on the female side of the machine, and bushing parts are placed on the male side.

Ejector pins are the parts that allow the parts to come out of the mold. It is included as a cylinder and lama cross-section. Female and male plates perform part separation processes for molds.

Top and bottom plates, support plates, and cores are also among the elements used in mold manufacturing.

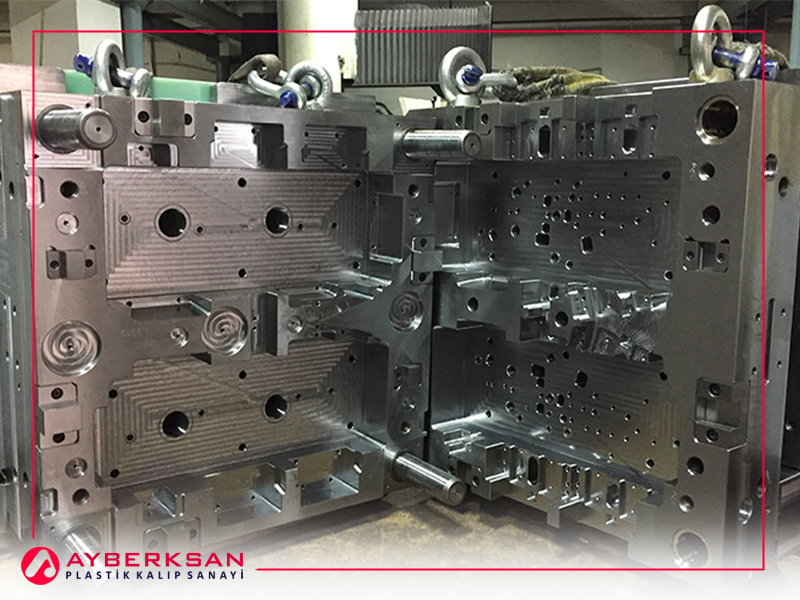

How is Plastic Mold Manufacturing Made?

Plastic molds are used in our daily life to produce plastics that are preferred in many areas. Plastic Molds start with the examination of the product to be produced and the computer-aided design of the mold, CAD, CAM, etc. for the relevant machines that will process after the mold set is ordered. It is produced after the processing of the steel in machines such as CNC, lathe, milling, and plunge erosion, and after collecting all the elements.