Injection Molding

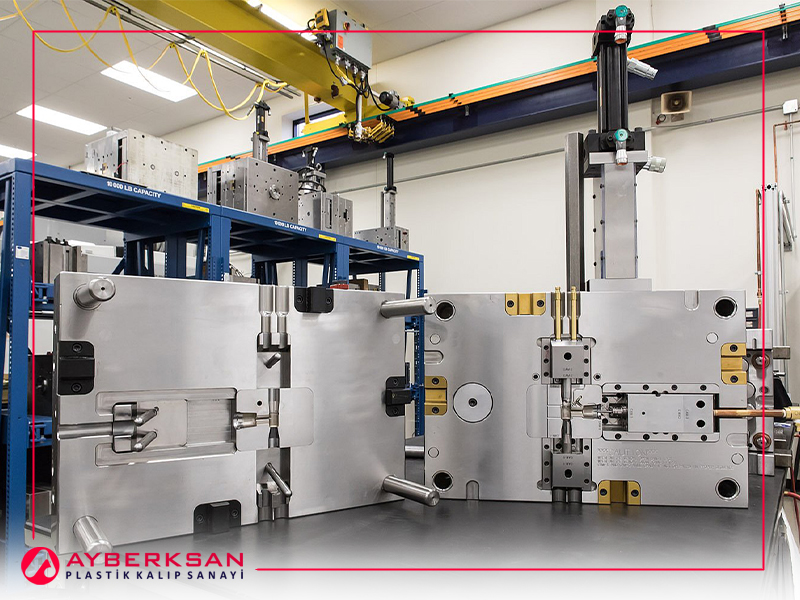

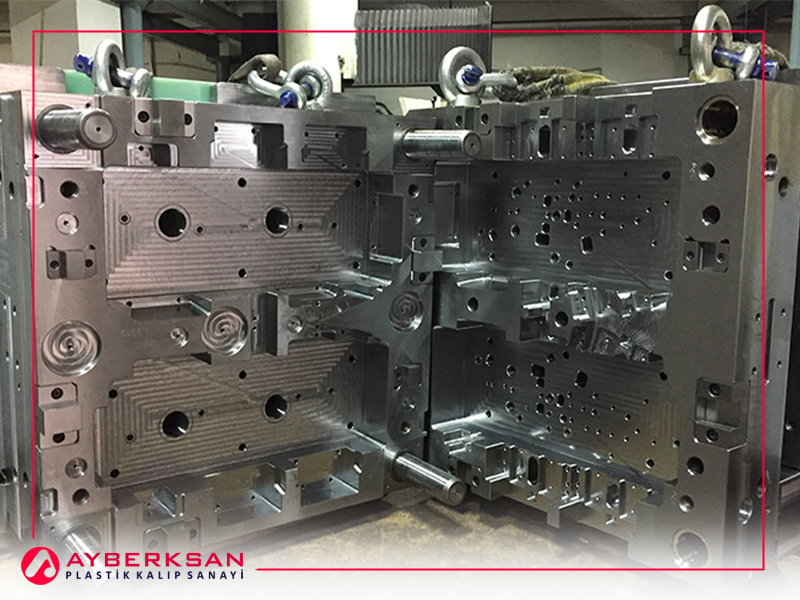

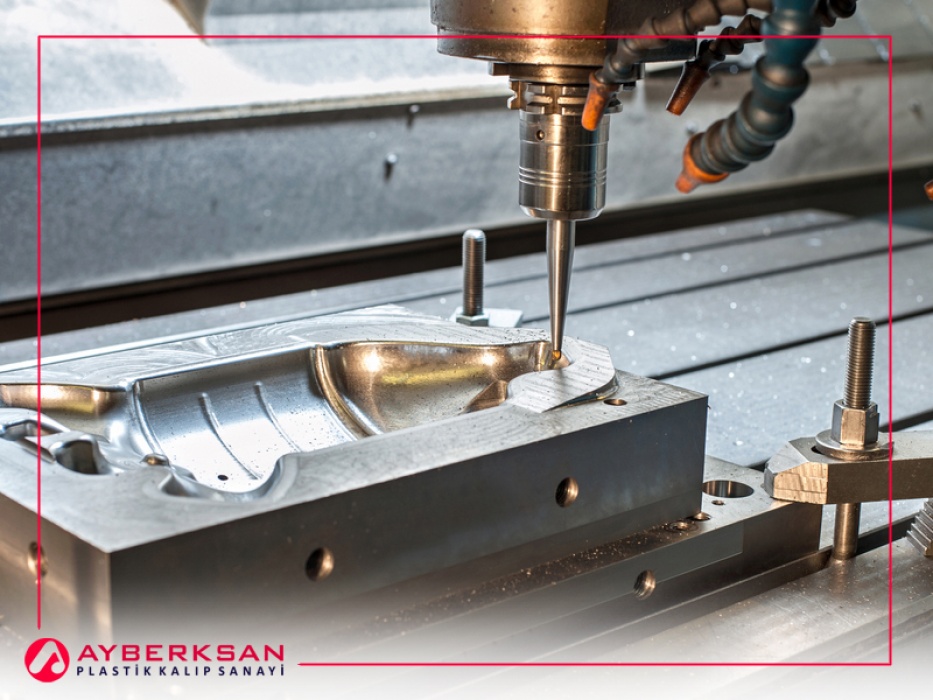

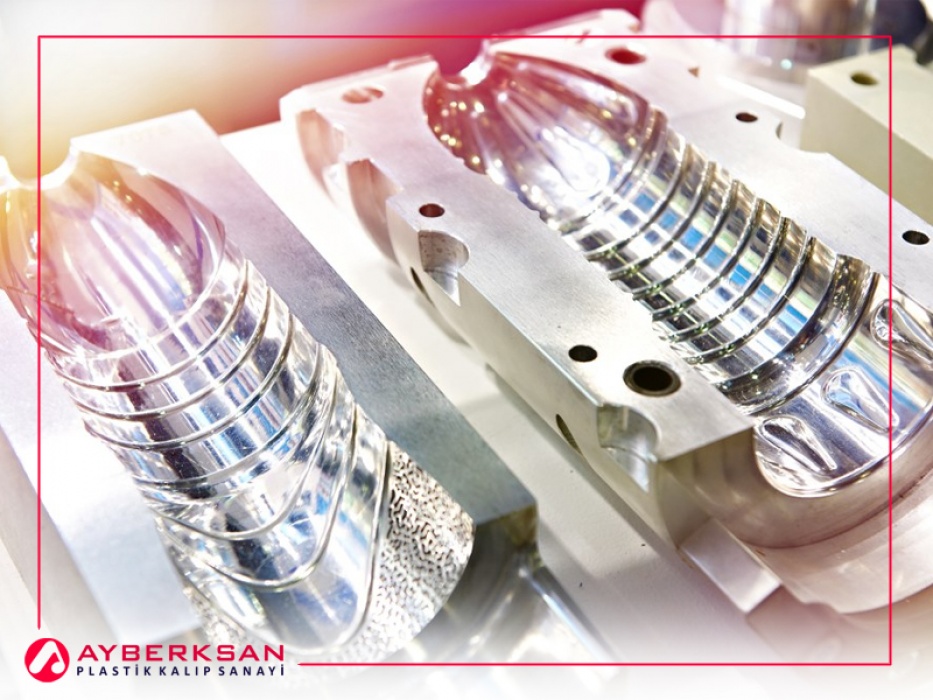

Injection molding is designed as desired from the mass production stage, which can be well designed and plastic injection of the same shape. In the injection molding process, the polymer granules are melted first. For molten plastics, it is placed in a mold to solidify and cool.

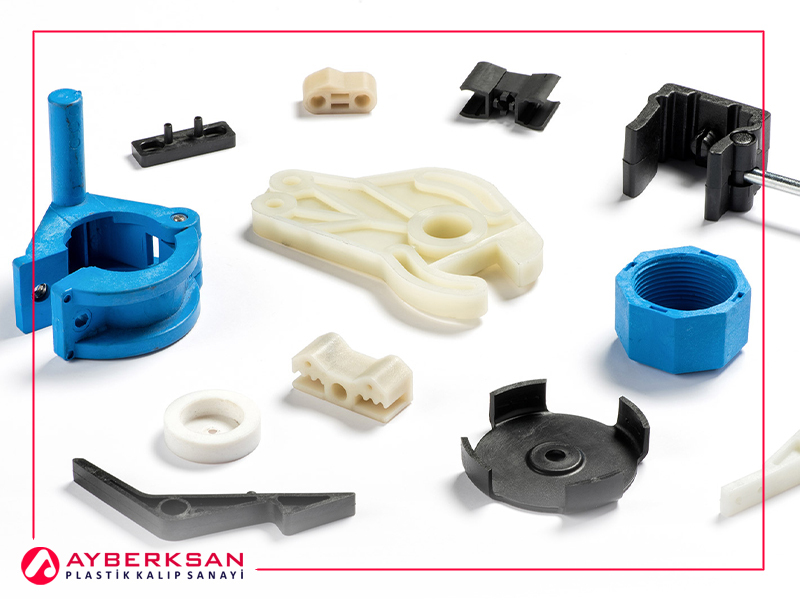

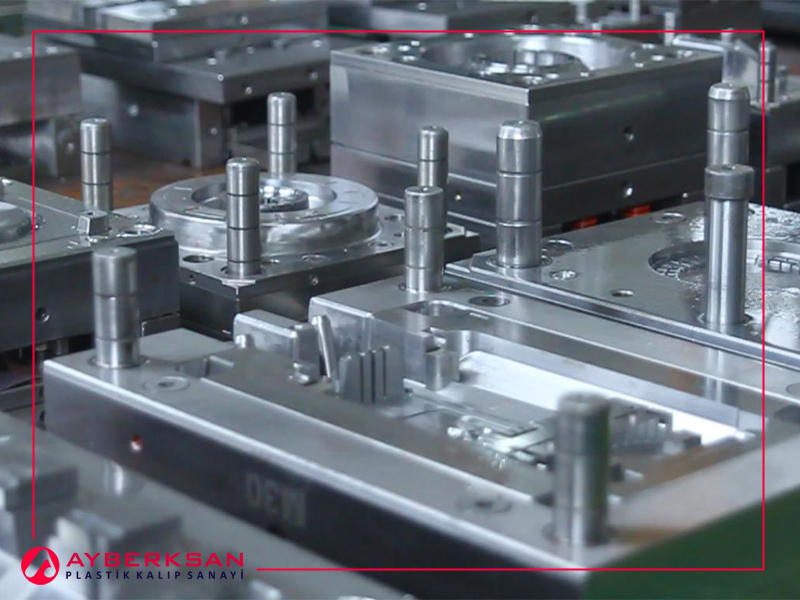

It can be both colored and configured differently. In this modeling method, the time until the design investment is a minimum of 4 weeks. The initial investment in the transaction is a bit high. In large enterprises, the costs are low. You are often preferred in this future. Patterns that have been designed can be used for depicted timed reproduction. It has a use for designs in concept.

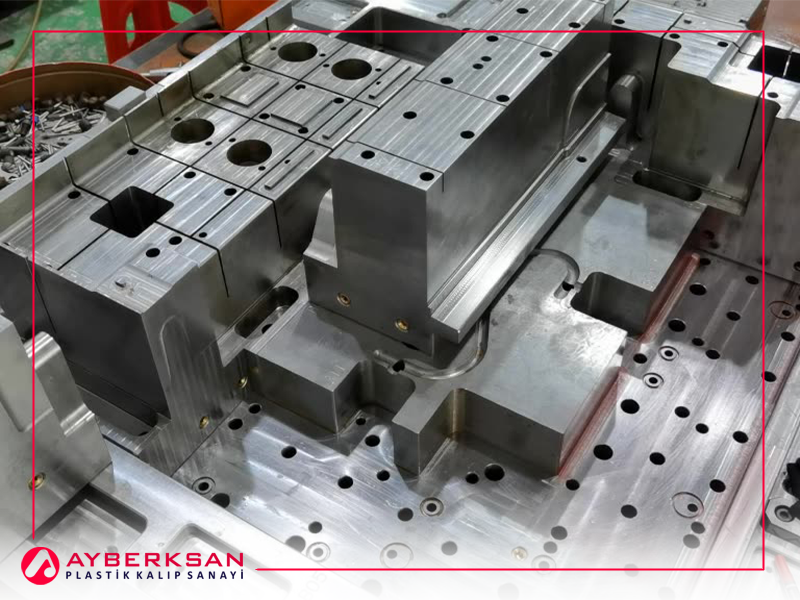

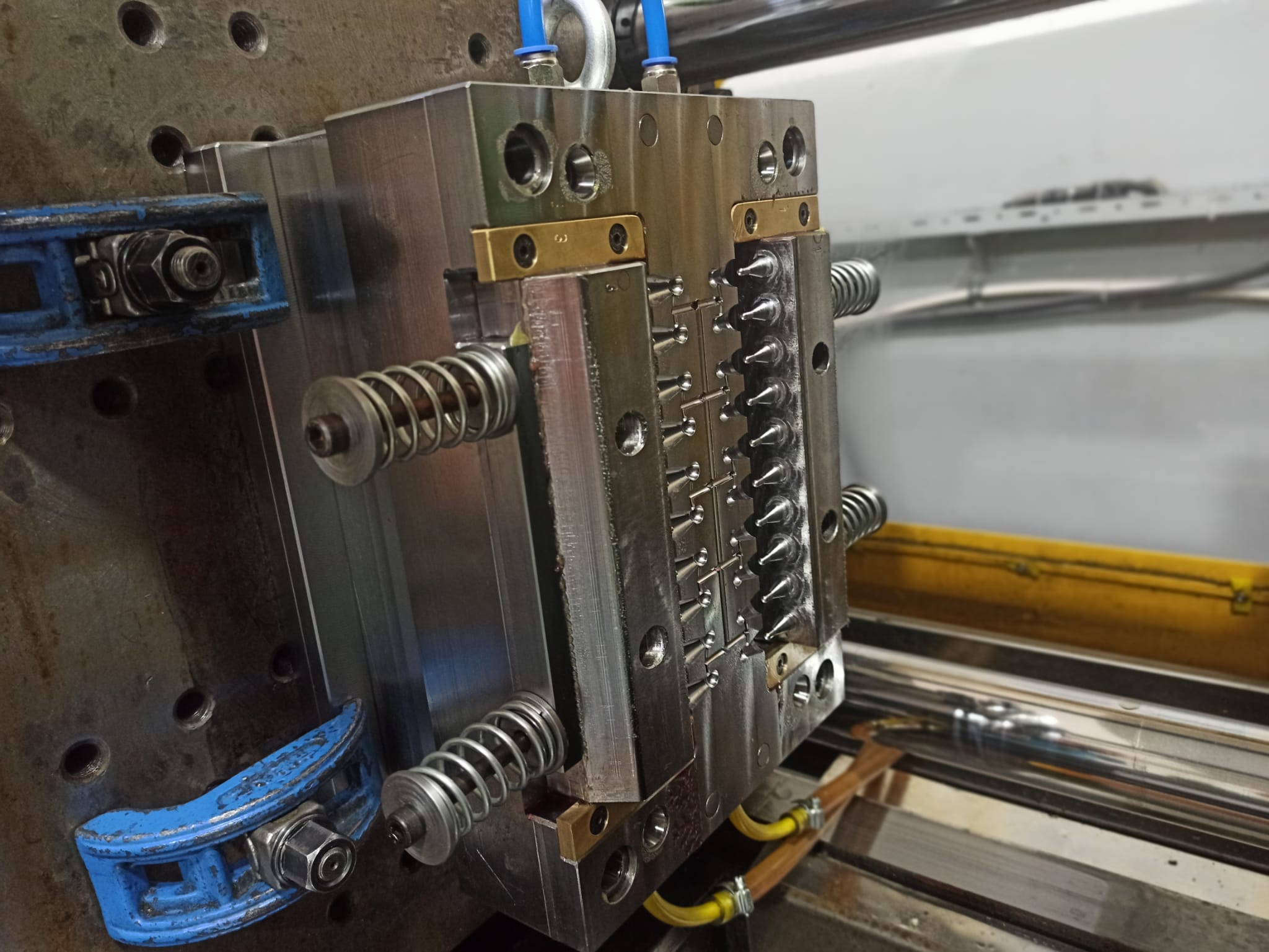

How is Injection Molding Made?

Injection molding is extremely common for our products and engineering applications. Many plastic items in every day will actually be this. If this claim is; High volumes of parts can be produced at an extreme cost per part. low cost; It can be between $0.1 and $1 per unit. However, this process gets a little high in the first place.

There are some special kits to own. However, when mass production is started in order to save the mold design, both the costs and the costs are met even more.

What are the Advantages of Injection Molding?

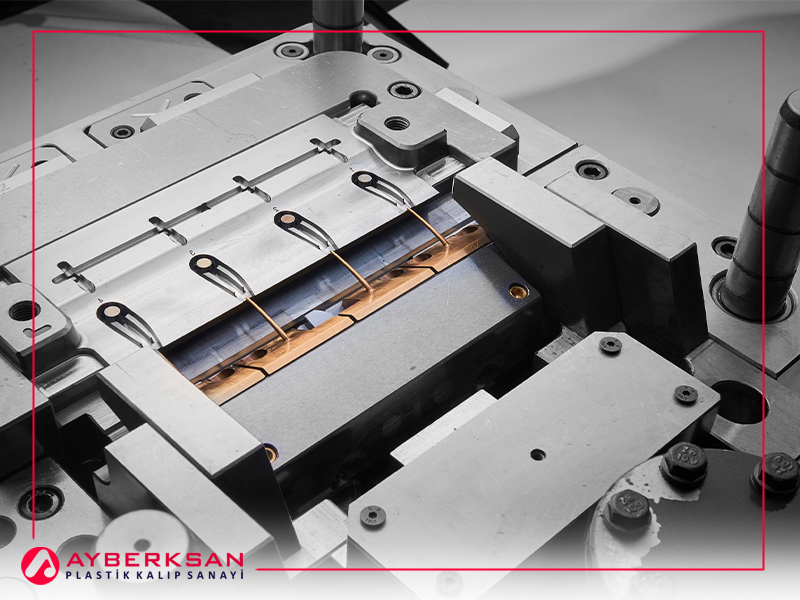

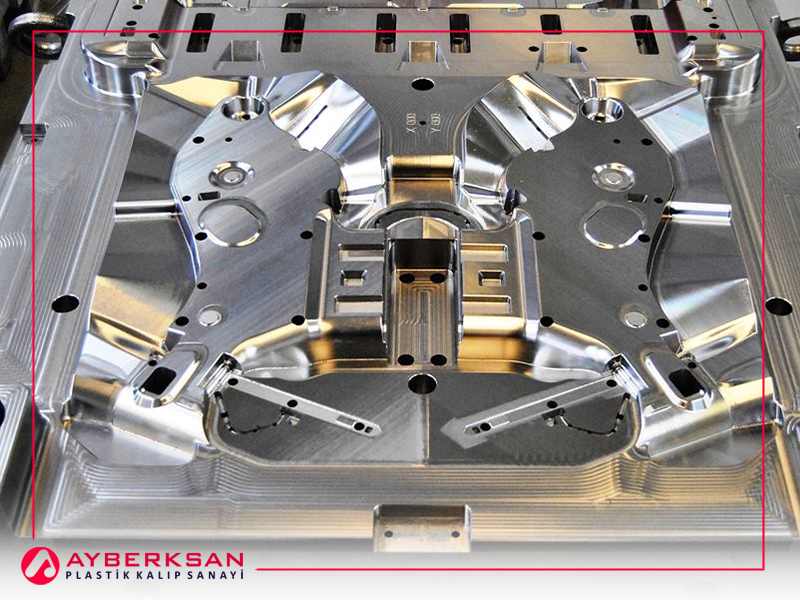

Any type of thermoplastic material has a chance to be molded using injection. At the same time, some silicones and thermosets can also be molded by injection. This is possible with different molds with different physical details to be designed.

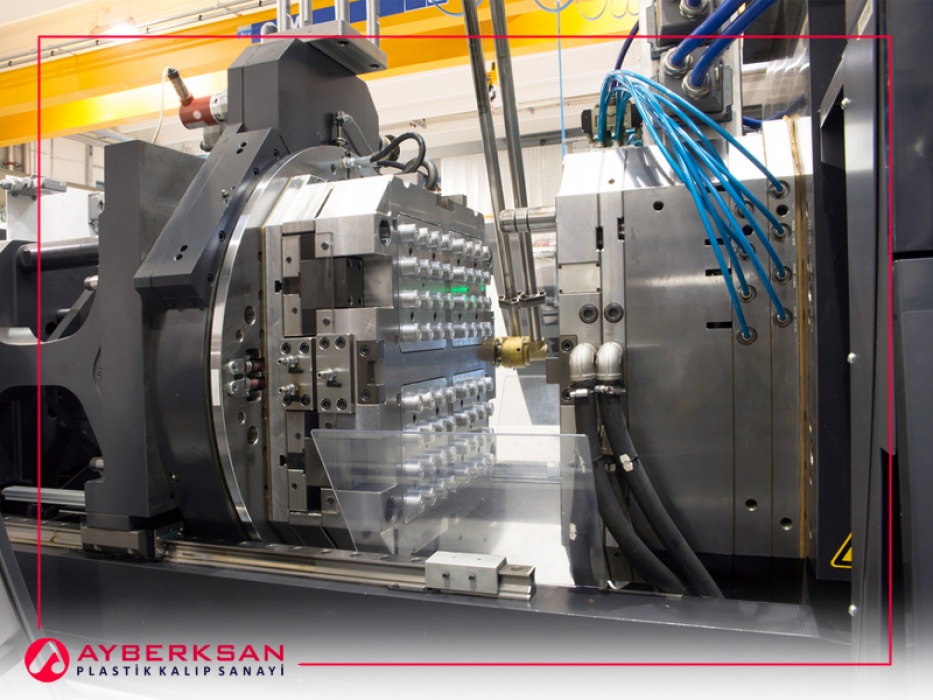

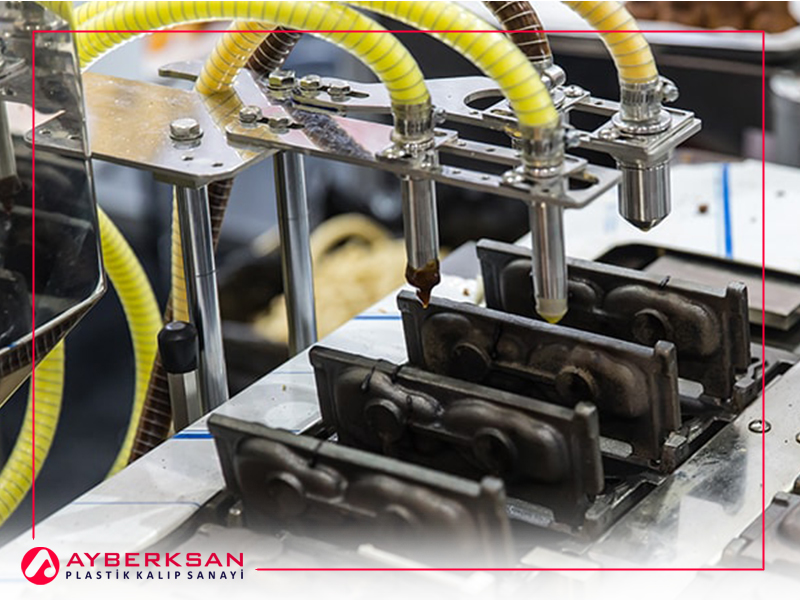

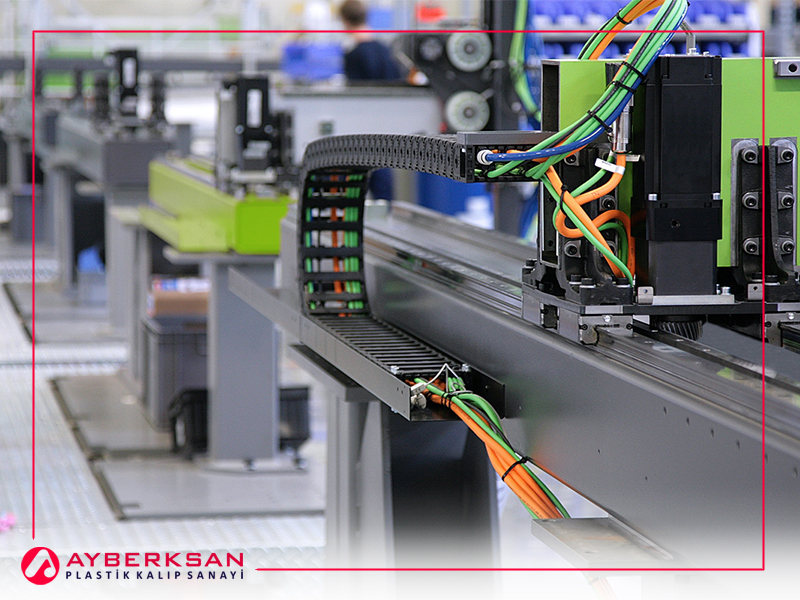

Injection molding processes can take between 15 and 120 seconds, depending on the size of the parts and the processing order of the molds. By increasing the number of mold chambers, more than one piece can be produced with a single mold. This contributes to the increase in production capacity.

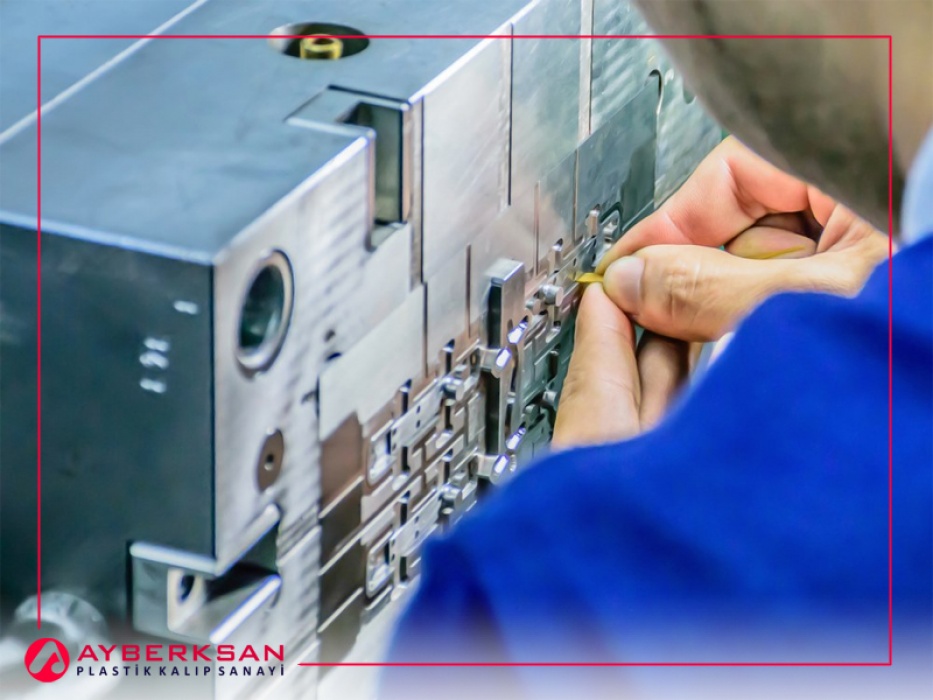

One of the most important advantages of injection molding is that it can produce products without the need for finishing. With Ayberksan, you can easily perform all kinds of injection molding processes. You can finalize your projects in a short time with expert staff and new generation devices.