Injection Molding Description

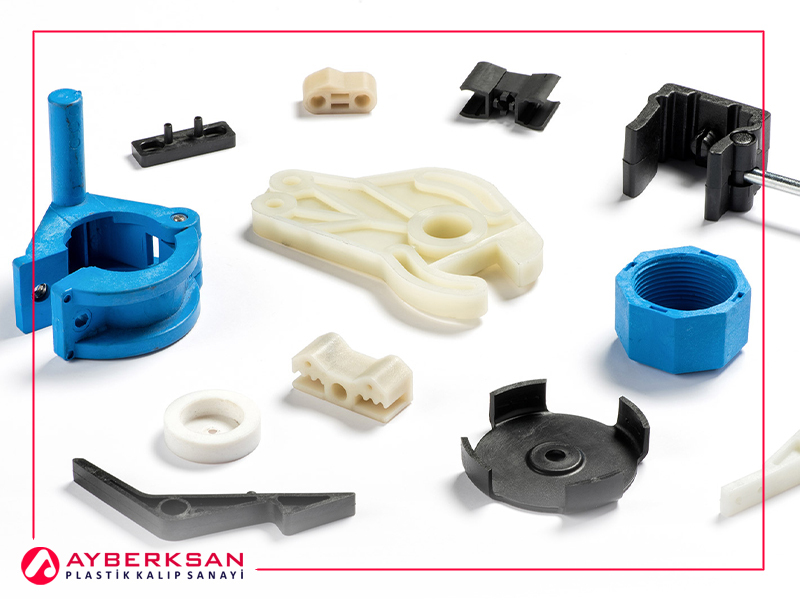

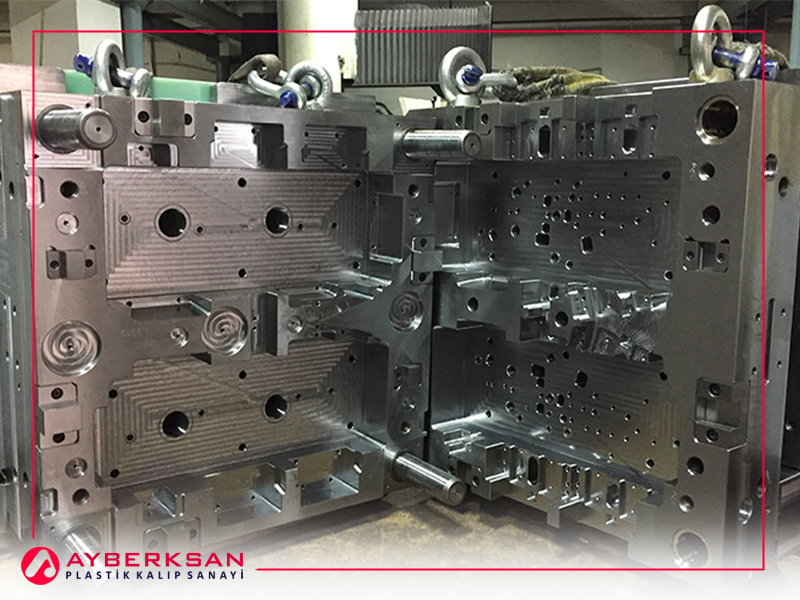

Injection molding can be defined as the production process of high-volume plastic parts. It starts with the manufacture of molds used in mass-production processes, where the same part is produced over and over again thousands or even millions of times. The most important advantage is the wide product range and the almost exact matching of the required physical properties. With its multi-layer plastic mold, mechanical properties, and attractive appearance, it is a process that has a minimal environmental impact and is inexpensive for its function.

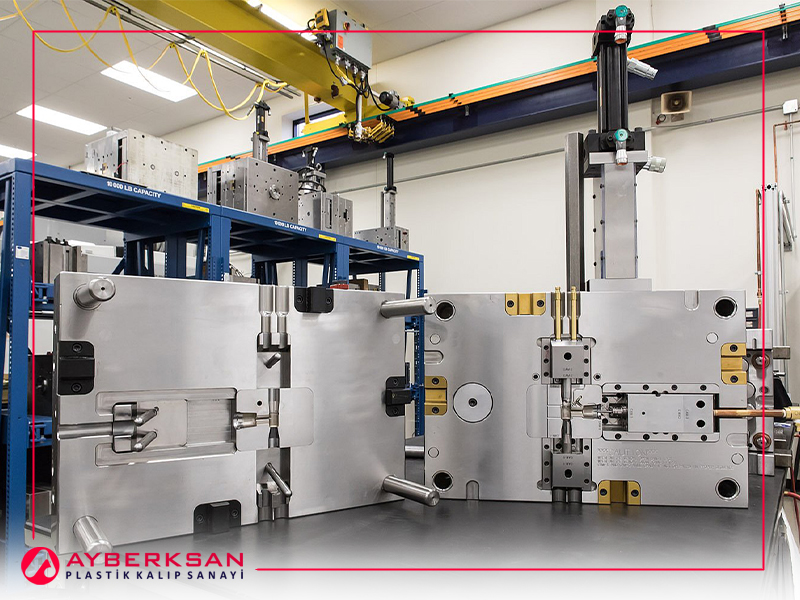

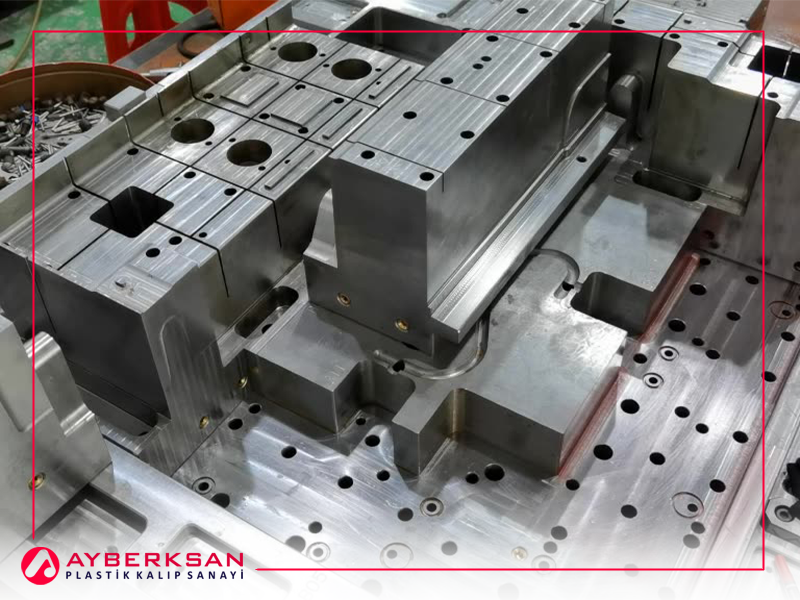

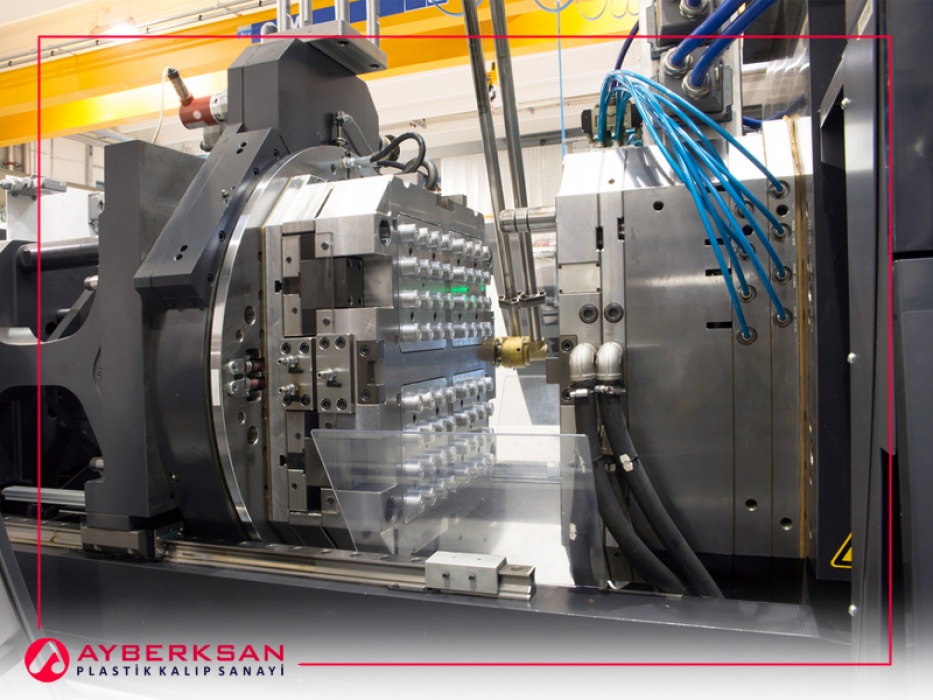

Injection Molding Process

Injection molding is the process of the emergence of molds designed to produce plastics used in many fields today. In this respect, it is preferred for engineering applications as well as consumer goods. Almost all plastic products around us are manufactured with injection molds. Because with technology, identical parts can be produced in very high quantities with very low unit costs. It is very economical to produce many identical plastic parts with injection molds. After the mold is shaped and assembled on the machine, the product can be produced very quickly and inexpensively.

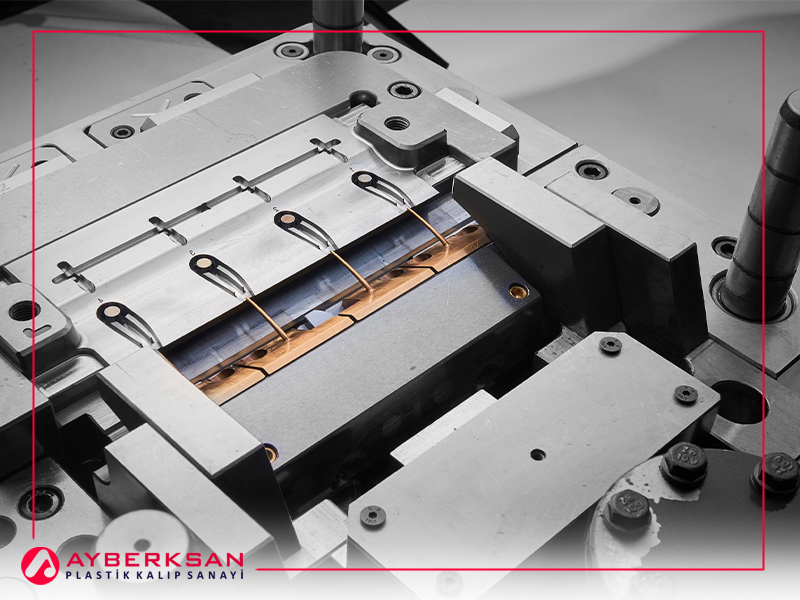

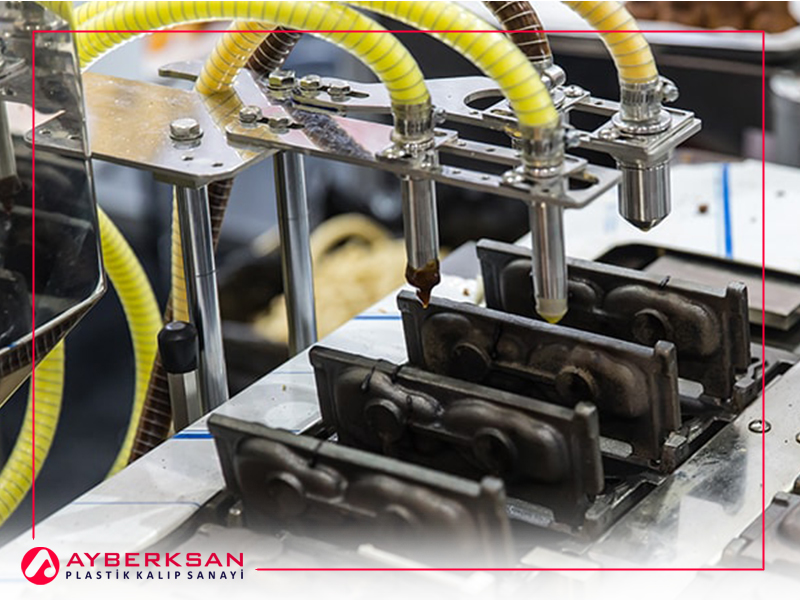

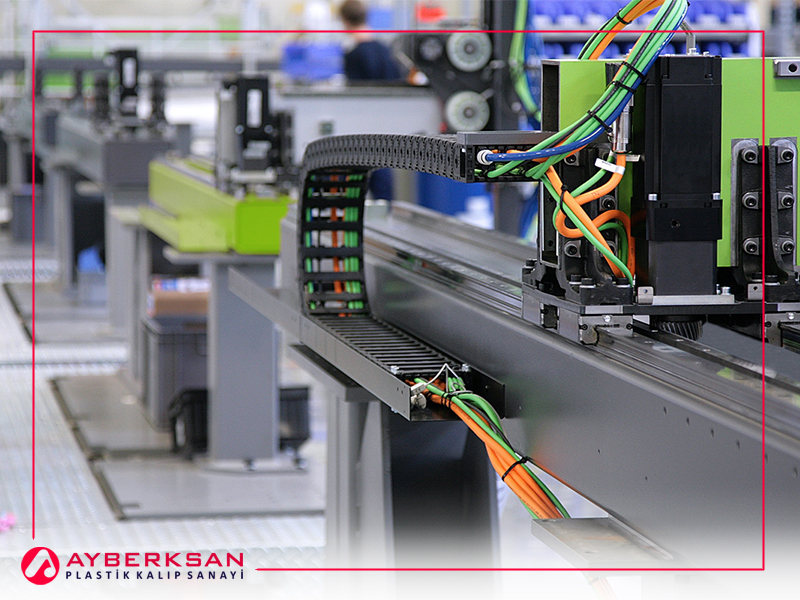

Injection Molding and Automation

The main purpose of businesses, factories, and organizations is to make the most of technology. In addition, it is aimed to make investments that can benefit financially in the best way by reducing the unit cost of everything used in services and products. Injection molding and automation come together widely in production processes as a tool that facilitates entrepreneurs through the use of technology. The surface qualities, raw materials and geometric shapes of the plastics to be produced in the injection mold are the main factors that will affect the automation. In case the mold runners are especially hot, it is essential that the necessary parameters are calculated correctly, and the application is done in the right order. The main purpose here is to make a profit from raw material and cycle time by eliminating the runner part left in the product printing process.

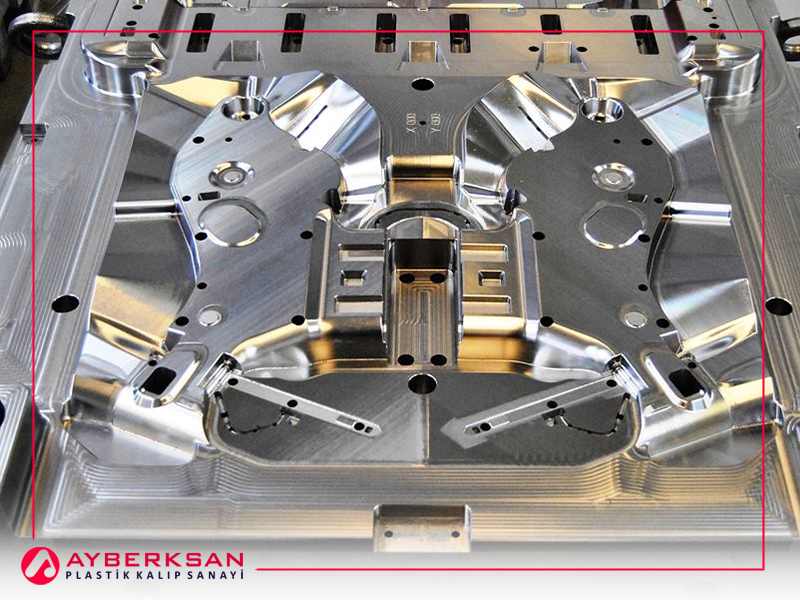

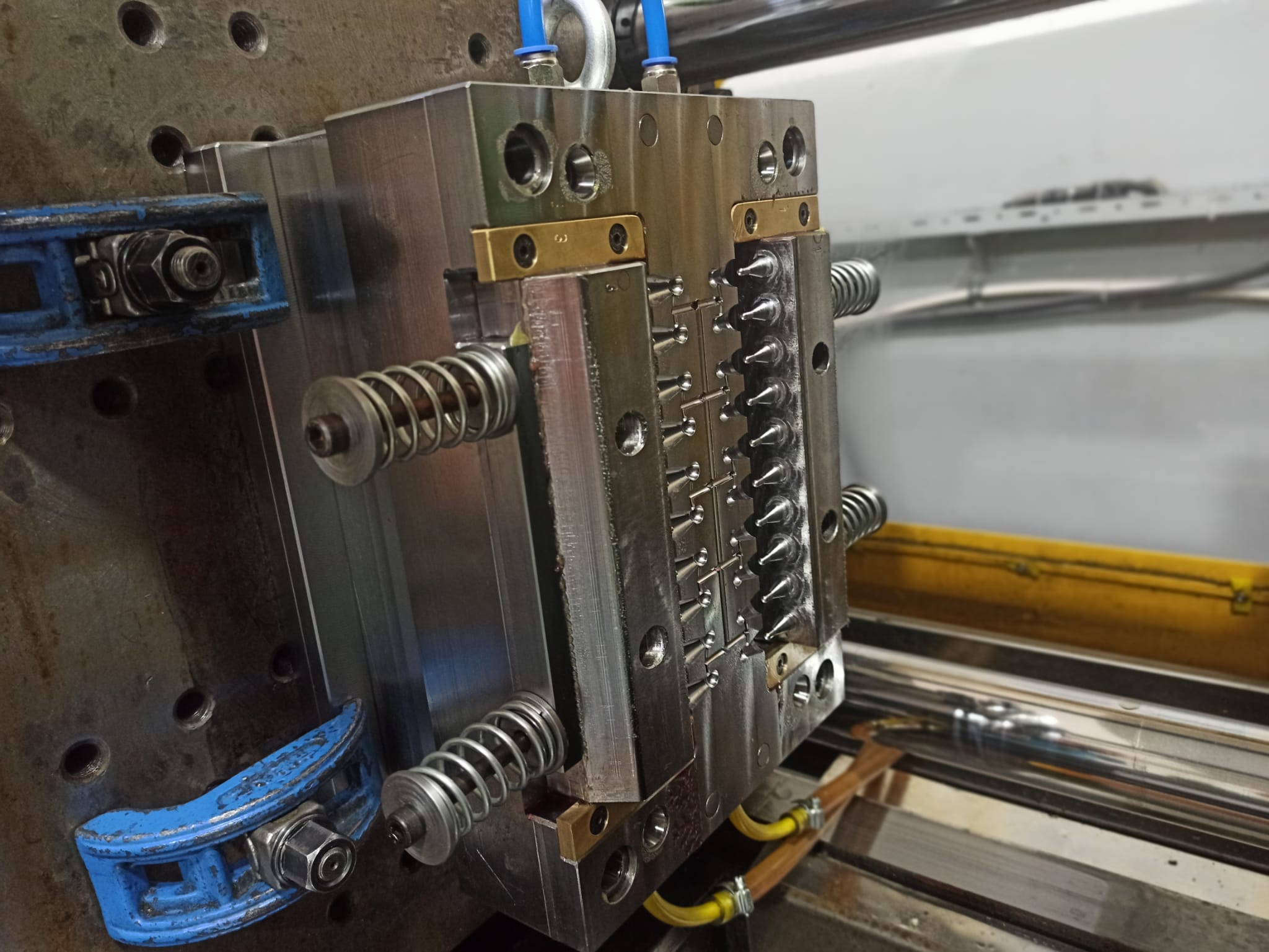

Injection Mold Alternatives

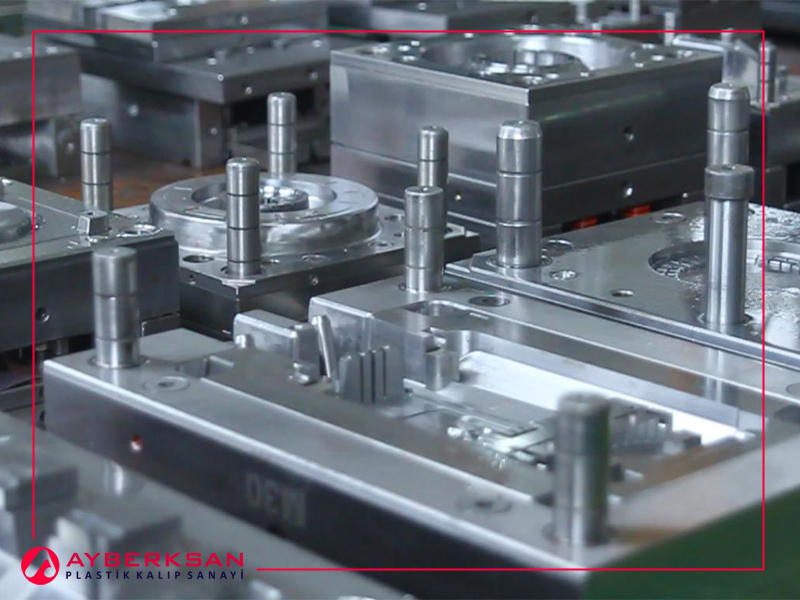

Injection molds are the most widely used products for mass production of plastic products in many fields with high surface and part quality. Although the cost of the molds used in the injection method is high, considering the plastic value produced by the injection mold in mass production, it is the most economical production method per piece. Before starting mass production, it is necessary to make sure that your part designs are complete. Otherwise, revision processes after mold manufacturing become very expensive. Also, during design and R&D, making decisions before production will reduce production costs.

At this stage, injection mold alternatives also help you.

• Aluminum mold

• Single cavity mold

• Multi-cavity mold

• Multi-part mold

• Insert mold

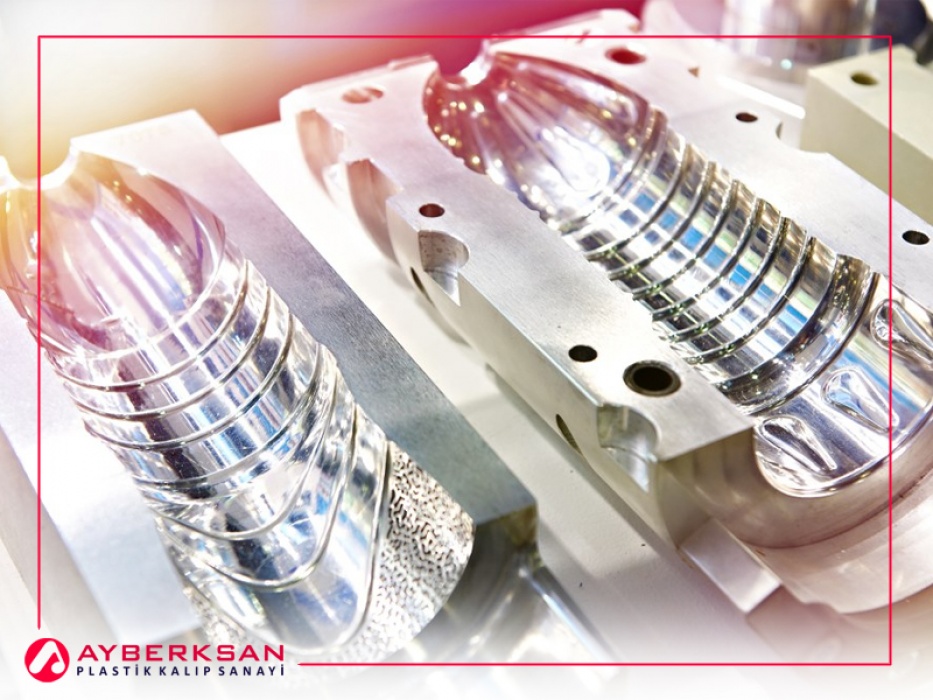

• Blow mold

Aluminum Injection Molding

After the aluminum material is produced, it goes through various processes and becomes usable in the industry. There are different processes in the manufacture of industrial products. Designers decide by which method the products will be made. There are different methods of producing aluminum material. These can be divided into pressureless casting and pressure casting. In the case of pressureless casting, a division into permanent casting and sand mold casting is possible. Besides, pressure casting is synonymous with injection molding. With aluminum injection molding technology, it is possible to produce high-volume products as in plastic injection molding. The molten aluminum material is pushed into the mold under certain pressure and the mold is completely filled. After cooling, the part is removed. Robots can also be used here for loading and unloading. You can benefit from the advantages of mass production by having your products produced with the aluminum injection molding method.

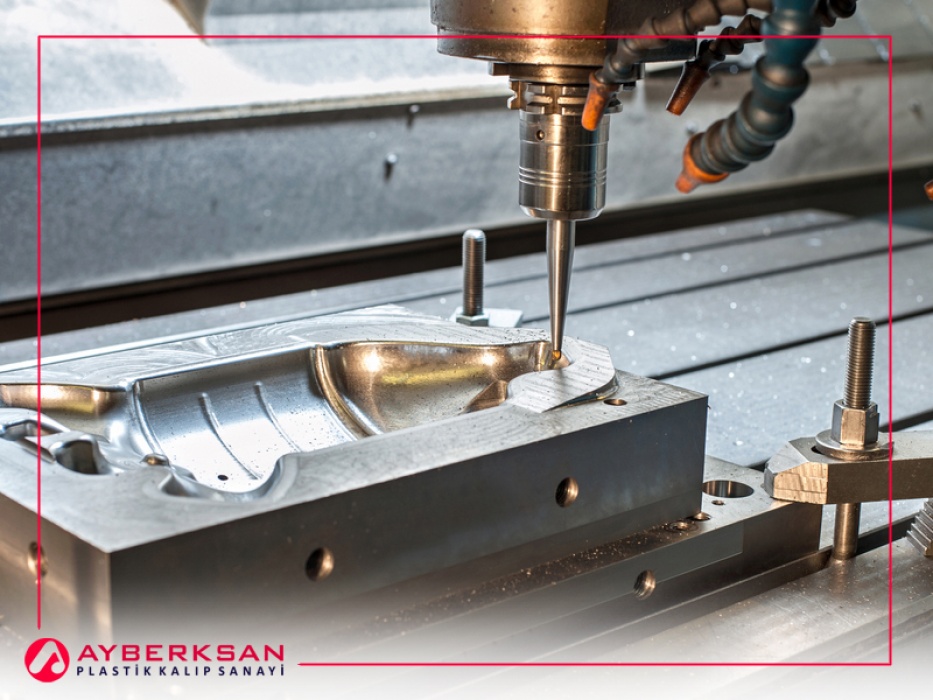

Injection Molding Companies

Injection molding companies provide their customers with high-quality, multi-component plastic parts and end-product manufacturing services through injection molding. Injection molding is the most cost-effective way to mass-produce a plastic part. During production, plastics are melted and injected into precision-machined metal molds. In other words, while thousands of plastic parts are made from a single metal mold, each part is made of the same quality. All these are offered to customers with a wide range of materials and surfaces.

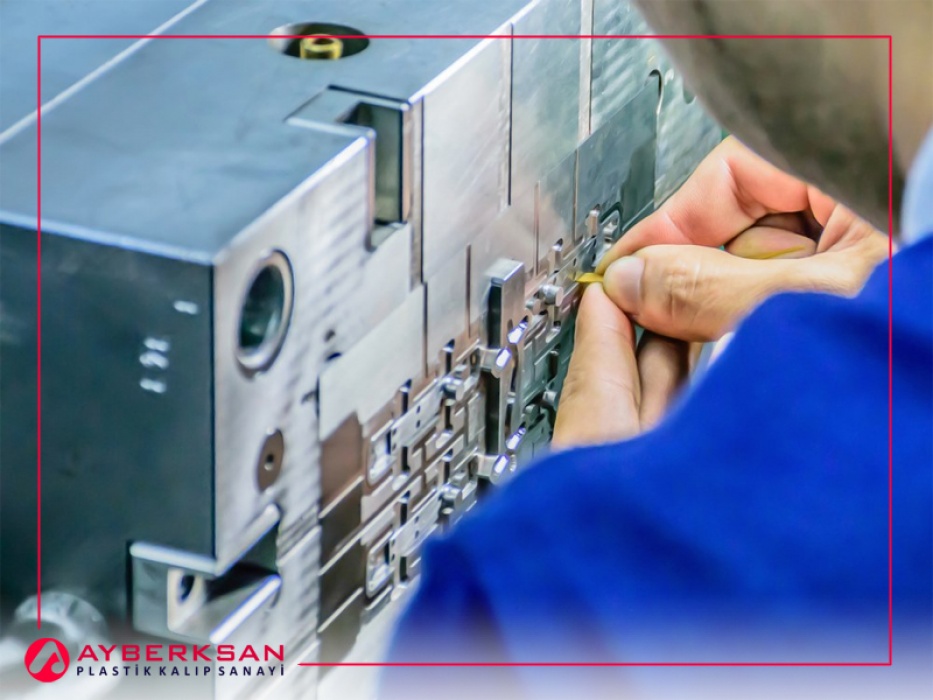

Injection Molding Companies Near Me

The design of plastic injection molds is generally based on the shaping of plastic materials by plastic injection molding. With the developing technologies, plastic is constantly changing and is being further developed as a structure. Therefore, the plastic injection molding process has become more and more important. The mold, which is one of the most important components of this manufacturing process, is a very difficult element to manufacture. Therefore, maximum care and precision should be shown in mold making and molding should be done with expert knowledge. In this respect, you can quickly benefit from this service with the injection molding companies near me.