Plastic Mold Production Process

Plastics used in many areas go through the plastic mold production process stages. Plastic, which is an important engineering material that can compete with metals and ceramics, has high heat and electrical insulation, high strength/light ratio, high resistance to chemical abrasion, and cheap production features. Due to these features, it is used in a wide variety of fields from the packaging industry to the aviation industry, from medical devices to kitchenware.

Plastic Mold Manufacturing Company

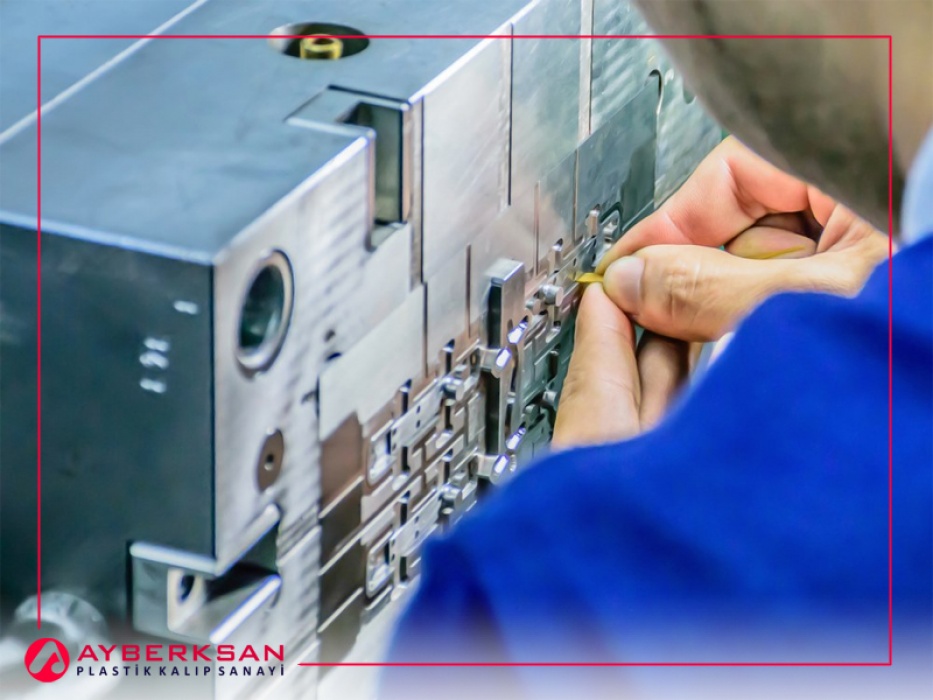

Compliance with the design of the final plastic product to be produced during mold making is very important. The mold form of the plastic product to be produced should be made by a team of experts in the field. In this respect, the plastic mold manufacturing company should present all the necessary requirements in mold making with its experienced expert team and technical infrastructure.

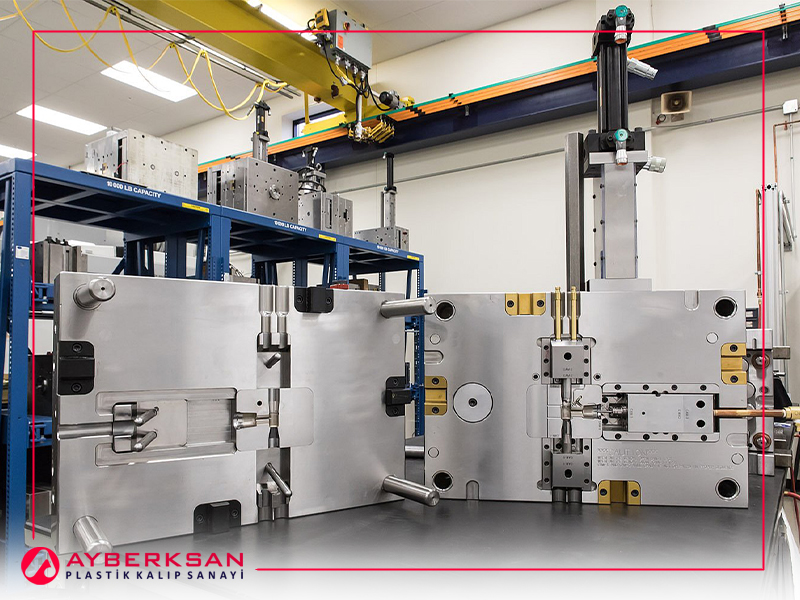

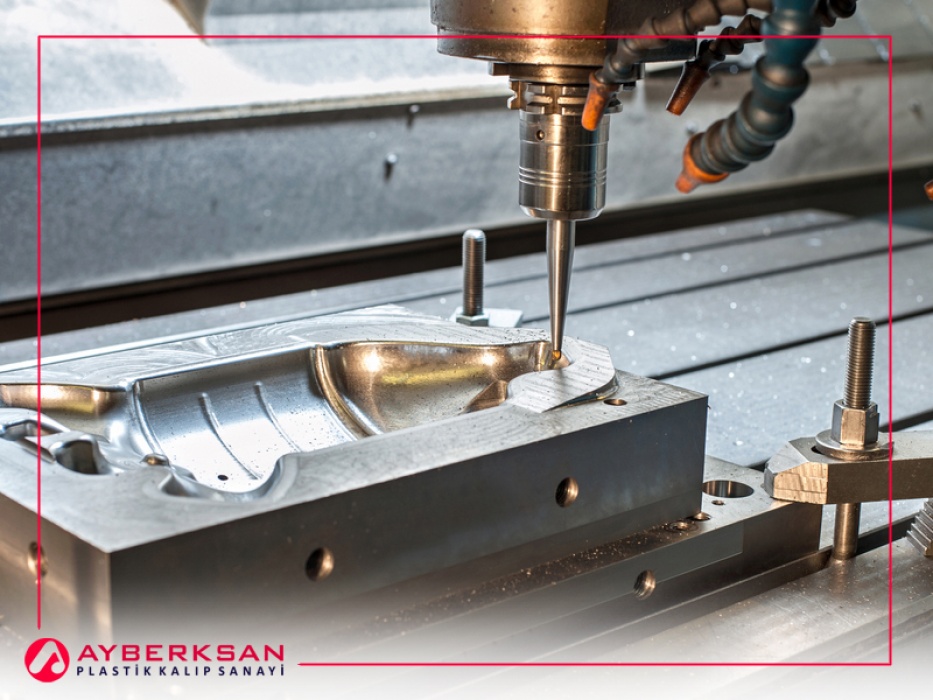

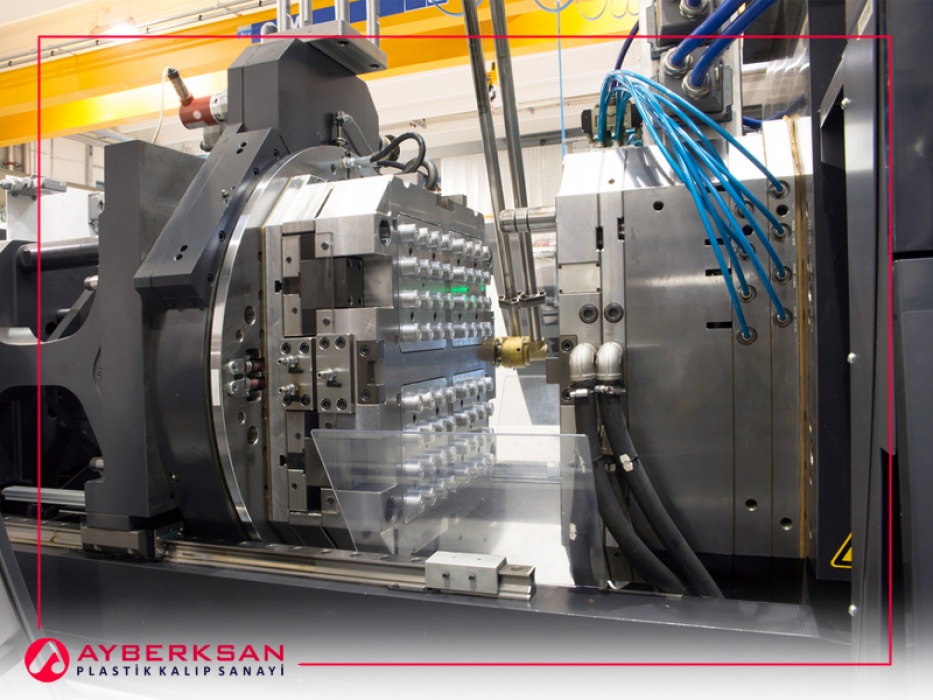

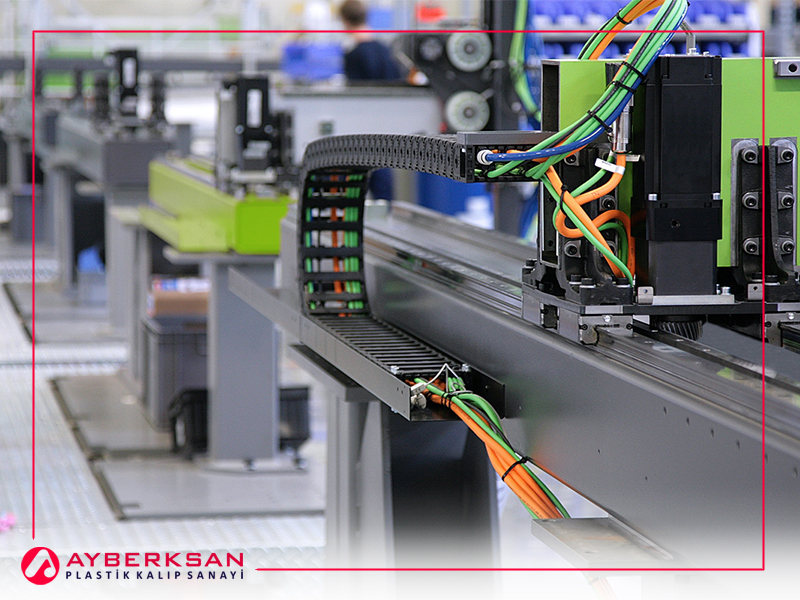

Plastic Injection Machine

During injection molding, the raw plastic material is pressed into a melt mold. Here the plastic cools and takes the shape of the mold. The injection molding machine, which heats the plastic material to the required temperature and injects it into the mold, allows it to cool after filling the material. In addition, these machines support the mechanism that includes the mechanism that allows it to be removed from the mold.

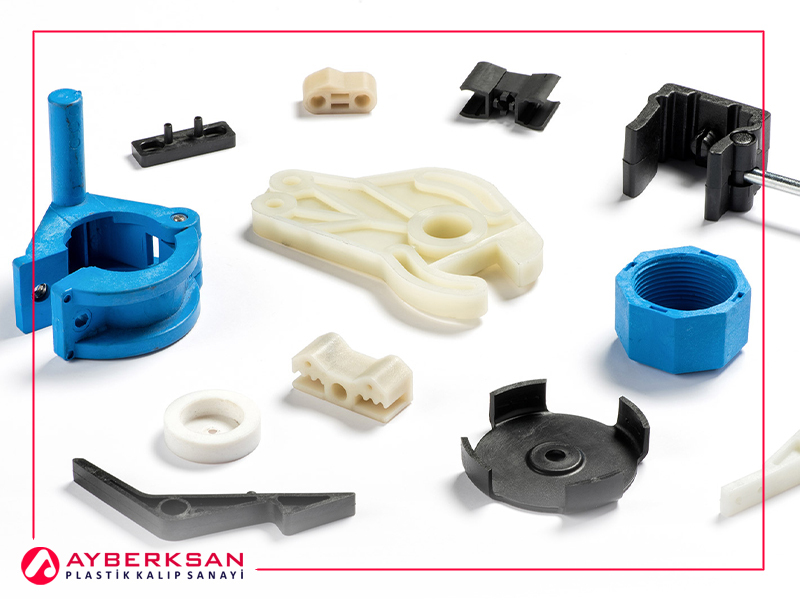

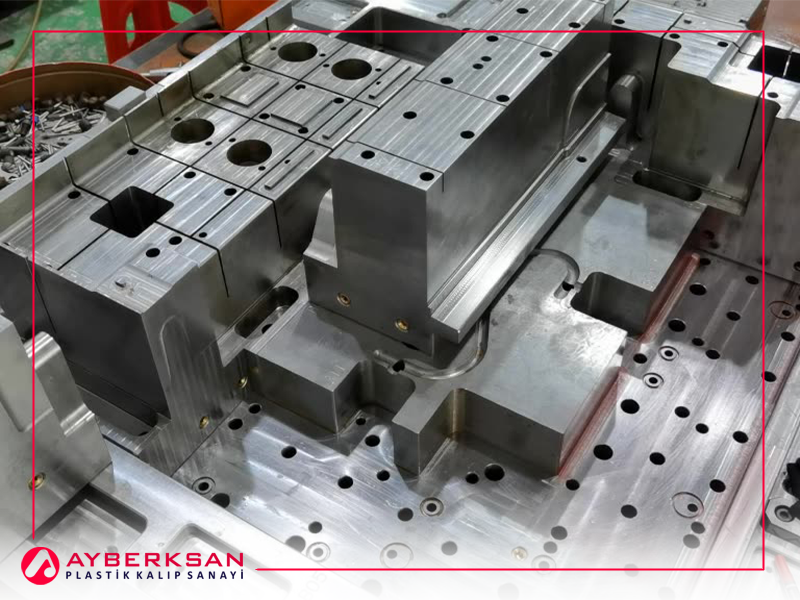

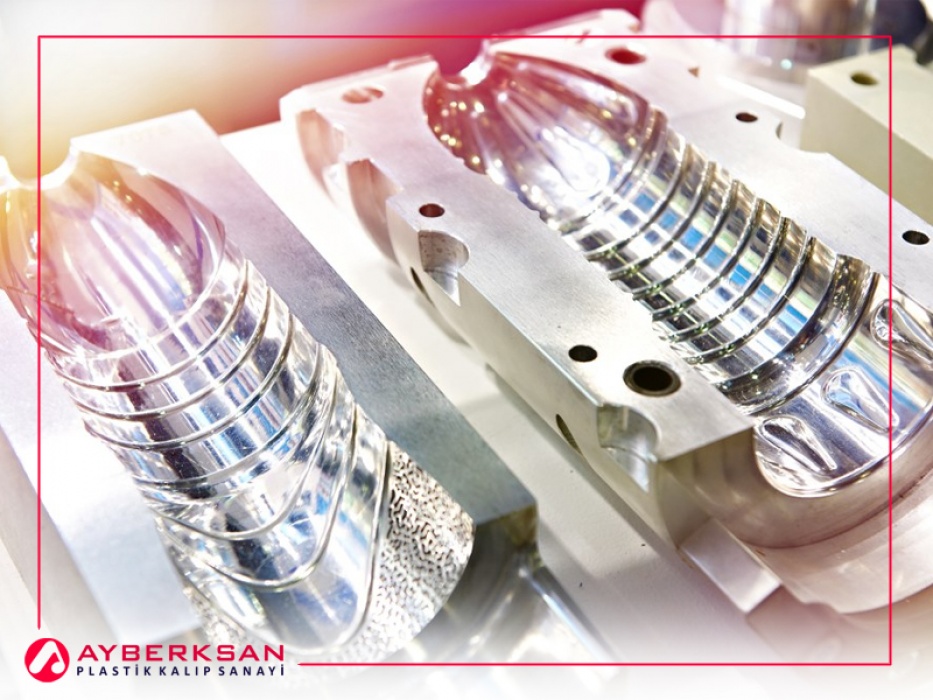

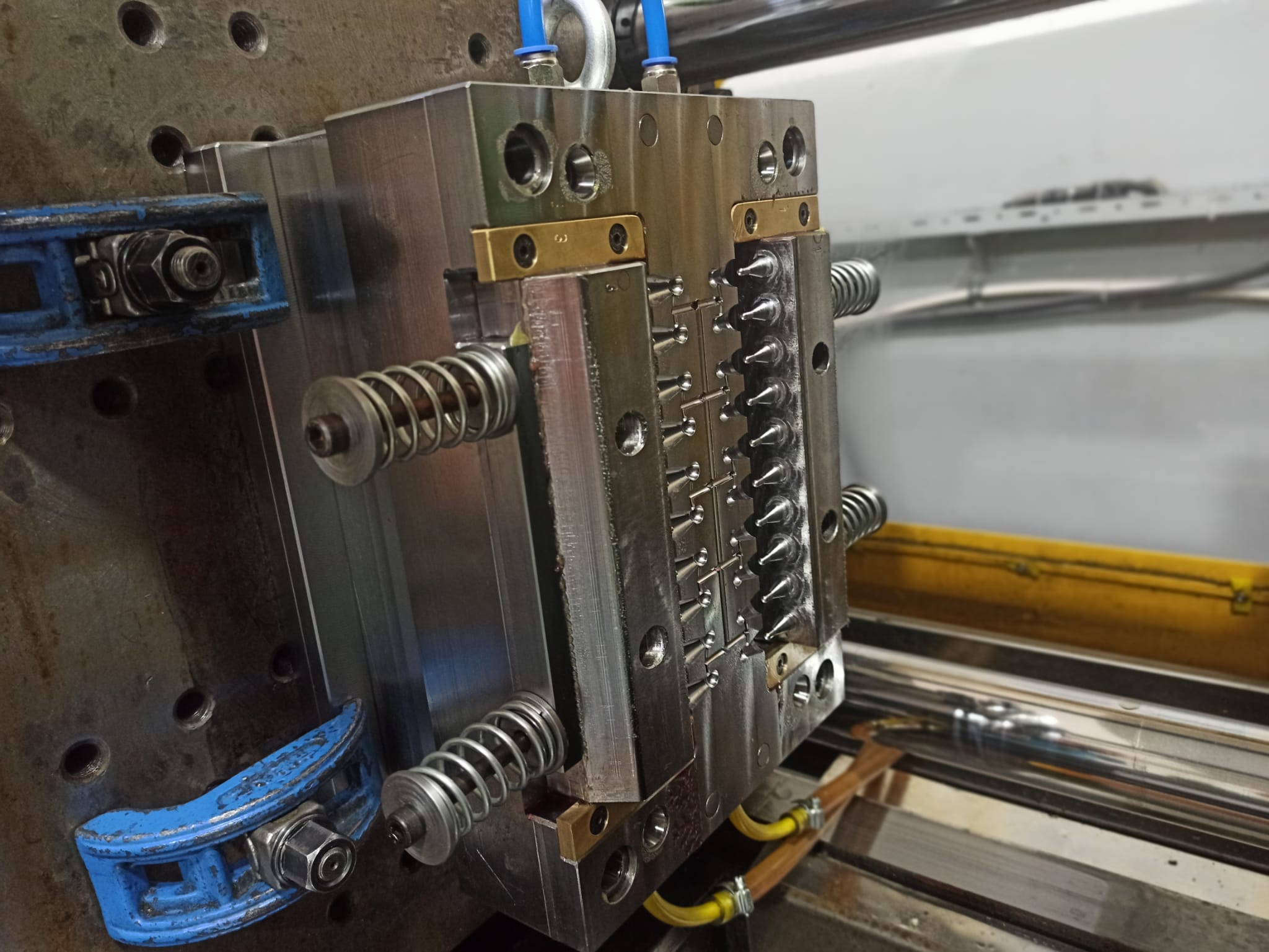

Plastic Injection Mold Manufacturing

Plastic injection is basically the injection of plastic material from the duct into the mold cavity at a high speed in a temperature range above the melt temperature. In this respect, plastic injection mold manufacturing is done in accordance with dimensions and tolerances. It is a production method that is widely used in many sectors because it is mass production. With this process, many products are produced, from the smallest parts to automotive and defense industry products.

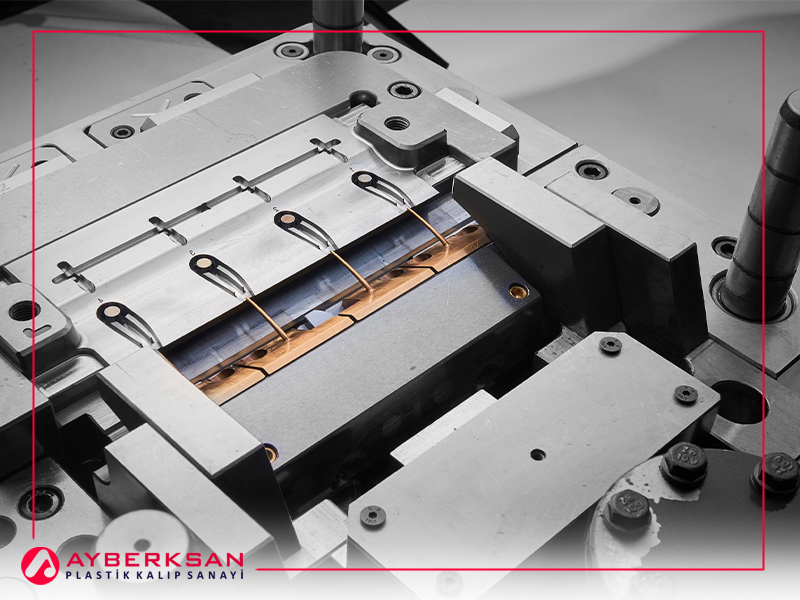

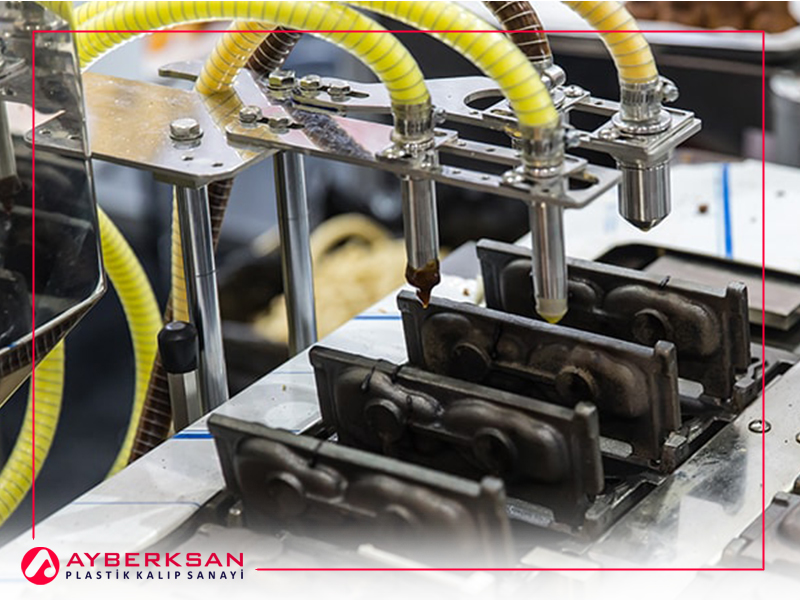

Plastic Production with Injection Molding

Plastic production with Injection Molding is a simple method. This process starts with connecting the mold to the plastic injection machine and feeding the powder raw material into the hopper. Then the raw material is heated and transferred to the hive where it is melted. The raw material melted in the hive passes through the nozzle under a certain pressure. Then the molten raw material moves through the mold under gradually changing pressure and becomes cold with the cooling process. Meanwhile, the cycle time and temperature of the plastic in the mold should be appropriate and attention should be paid to the shrinkage of the product falling with the pusher in the molds.

Plastic Mold Manufacturing South Bend

All processes, from the design of the molds used in plastic injection molding to production, are made by the experienced team of plastic mold manufacturing companies in South Bend. In this respect, plastic injection molds are designed and produced by trained injection molders and designers with the quality and precision that can produce millions of parts with years of meticulous work.

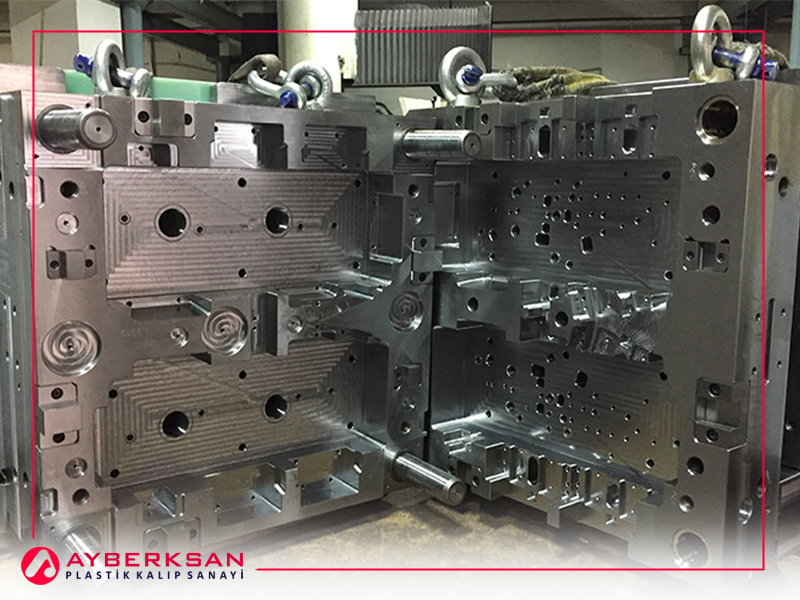

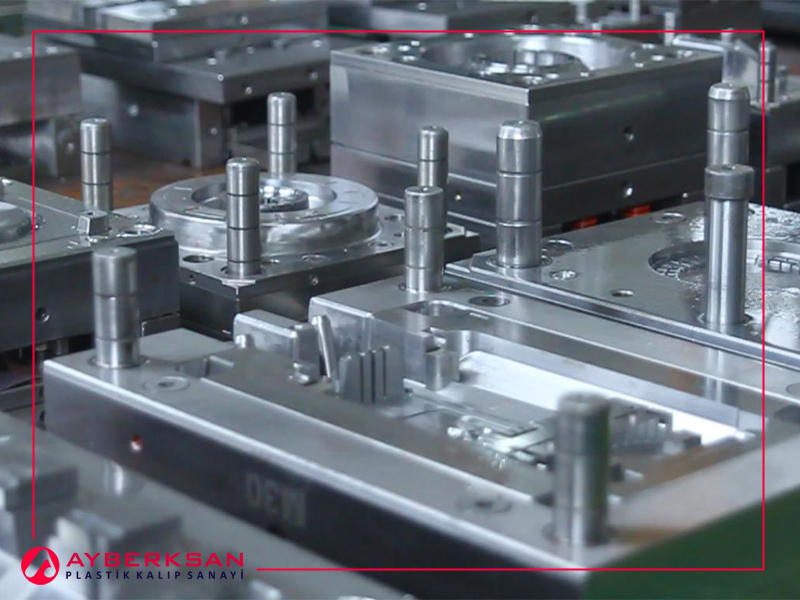

Plastic Mold Manufacturing South Bend Indiana

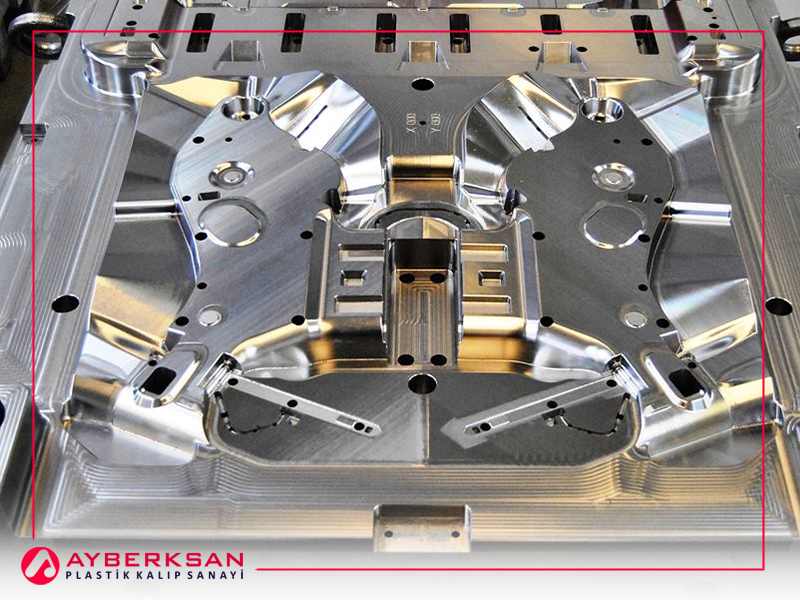

The process from the idea of the plastic material to be produced to the realization of mass production is the production of molds. Mold making with a direct effect on the final product requires very precise engineering effort, modeling, drawing, and editing with advanced technology software in the computer environment. At this stage, South Bend Indiana companies, which manufacture plastic molds, come into play.

Bangalore Plastic Mold Manufacturers

Those who want to manufacture plastic materials with the plastic mold process should seek service from manufacturers who have experience in the field and have a legitimate place in the market with the materials they produce and can produce safely and economically. In this respect, Bangalore plastic mold manufacturers provide the service you need.

Plastic Mold Makers Canada

Plastic mold manufacturers work from the drawings that contain the general contours, not from the full drawing of the mold when applying them to the mold plate from the drawings they have. During work, he reads additional details from the drawings and applies them to the form. Work begins with the determination of reference points on the instrument. In this respect, if you need such a service, plastic mold manufacturers provide services for those living in the Canadian region.

Plastic Molding Company

The company that makes plastic molds provides services for plastic molding processes. The geometry and surface properties of the part to be molded are transferred directly to the injection molded part. Thanks to these processes, advantages such as low cost, less material loss, high production speed, and automation can be benefited.

Plastic Molding Molds Manufacturers Pune

Many issues need to be considered while making the mold. In order to gain advantages in mold manufacturing and application, it is necessary to use the existing technology sufficiently. While simple shapes can only be processed with the coordinates specified by the operator, complex shapes can be processed with machine-oriented coordinates with the help of CAD/CAM programs. At this stage, it is necessary to get services from the producers. In this respect, manufacturers of plastic molding molds provide support for those who need this service in the Pune region.