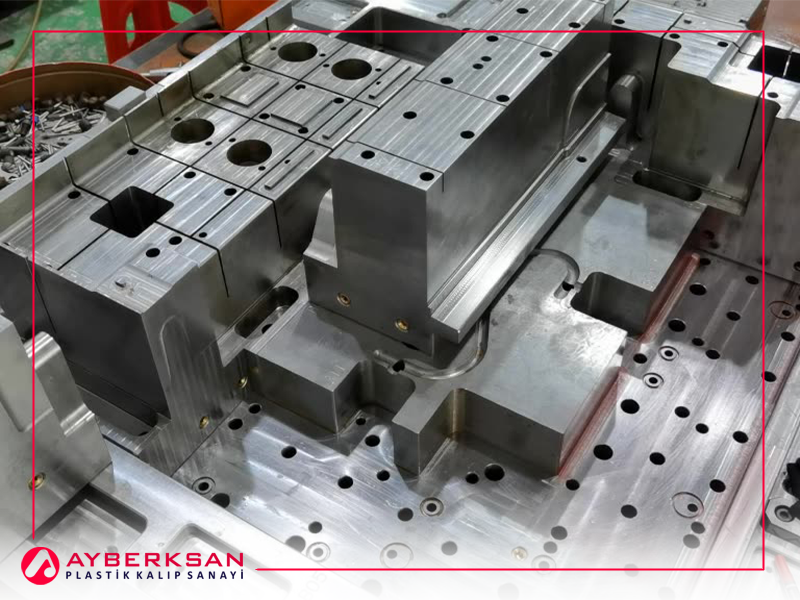

Injection Mold Manufacturing

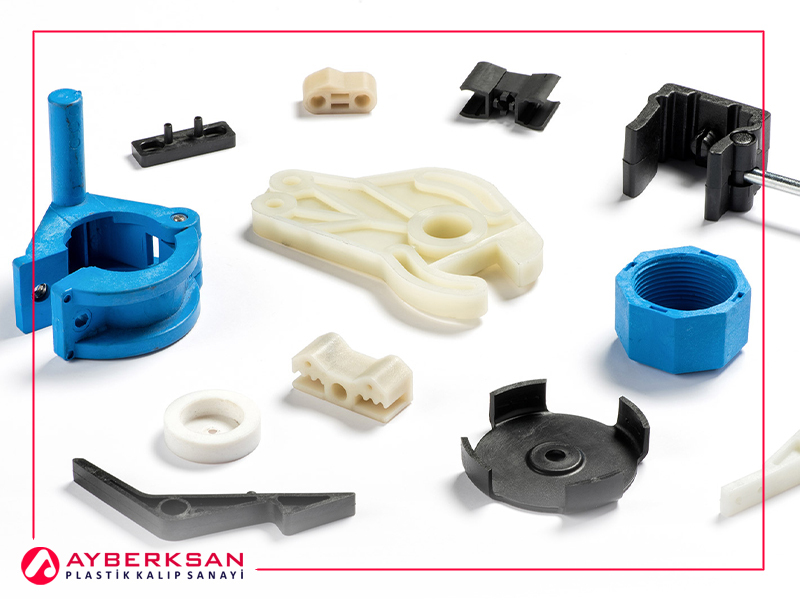

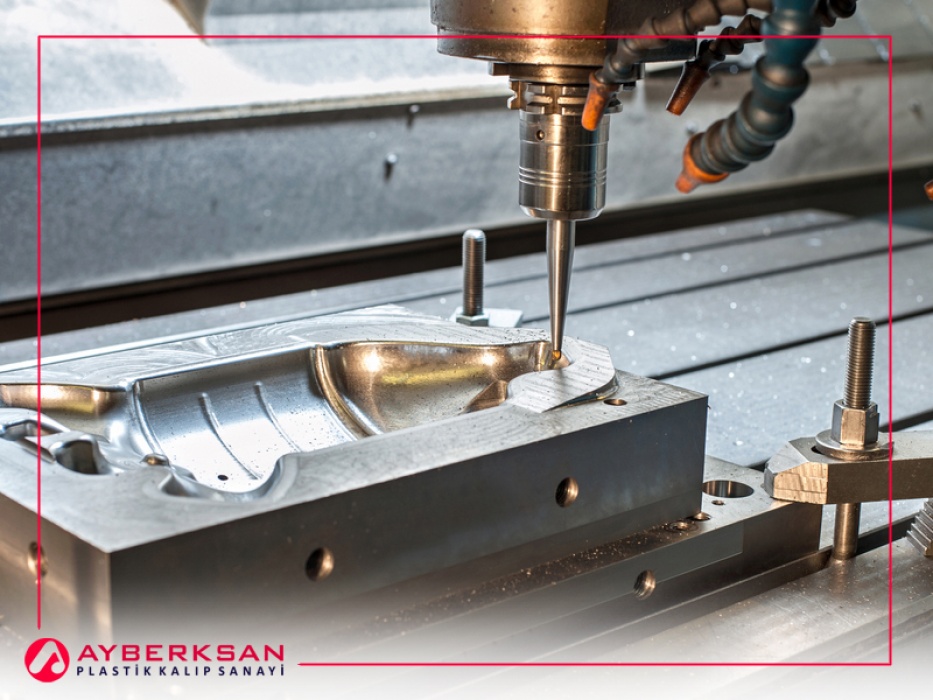

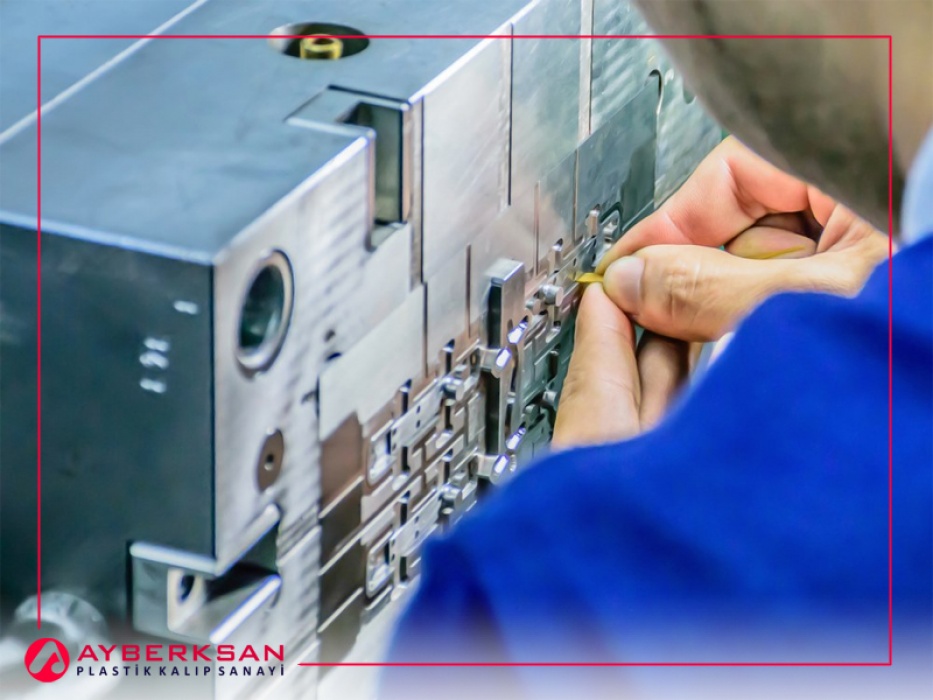

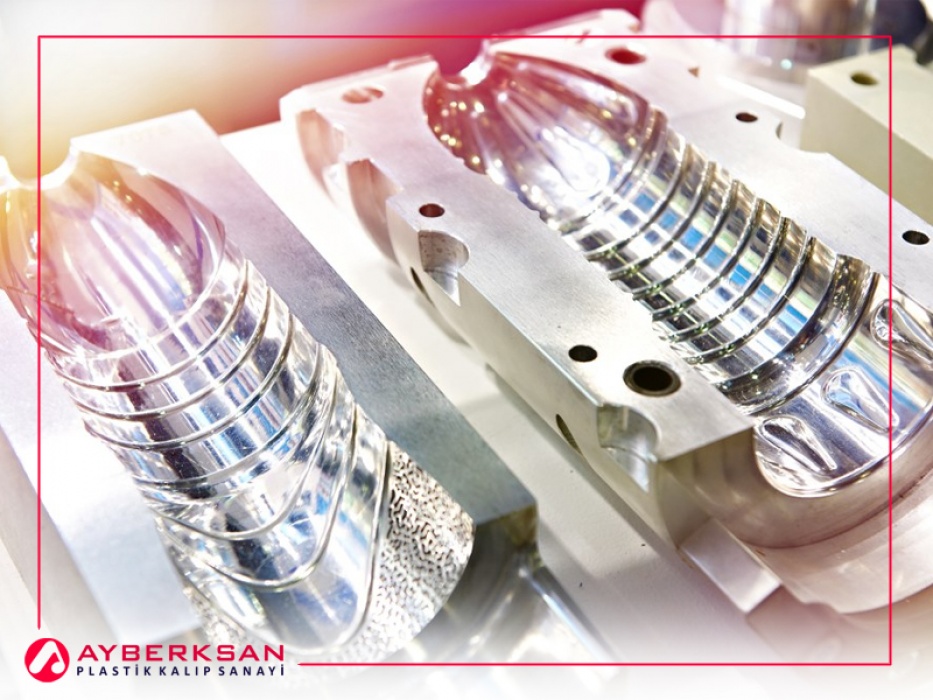

Injection mold manufacturing is a form in which most types of plastic are produced, depending on the application. The plastic raw material melted in the injection furnace is injected into the mold at high pressure. The plastic cooled in the mold takes the shape of the mold. The duration of this process is so short that it can be measured in seconds. This process allows you to produce plastic parts of very precise dimensions. Unsuitable products can be recycled and reshaped. The machines used for manufacturing have high production capacity. In addition to providing easy and fast mass production, it guarantees fewer labor costs. In some cases, it can be produced automatically without human effort. Since the final product is presented for the first time, no post-processing is usually required. Dimensional accuracy is available and manufacturing tolerances are the same. This makes it possible to manufacture very small parts that cannot be produced by other methods. In addition, it provides economical and fast production.

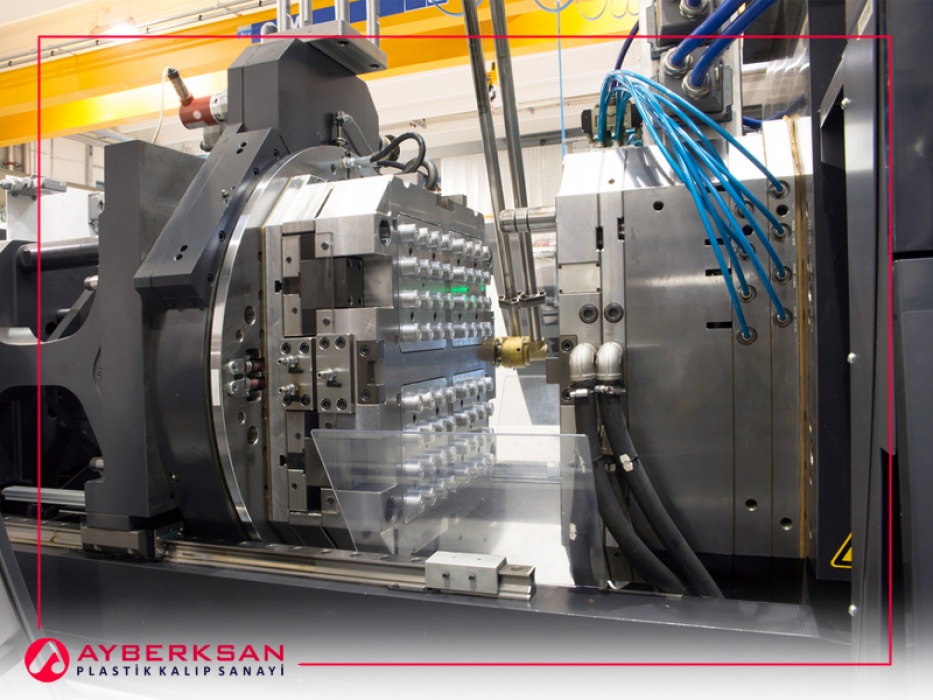

How Does a Plastic Injection Molding Machine Work?

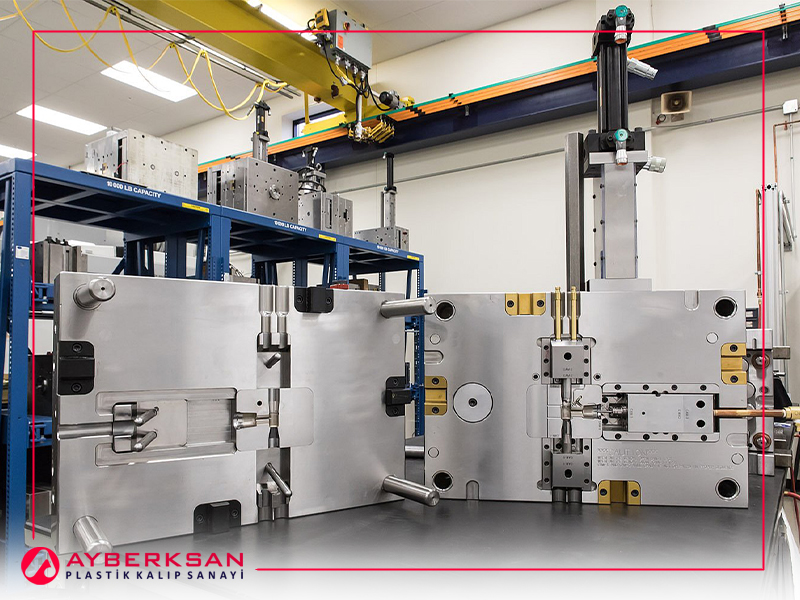

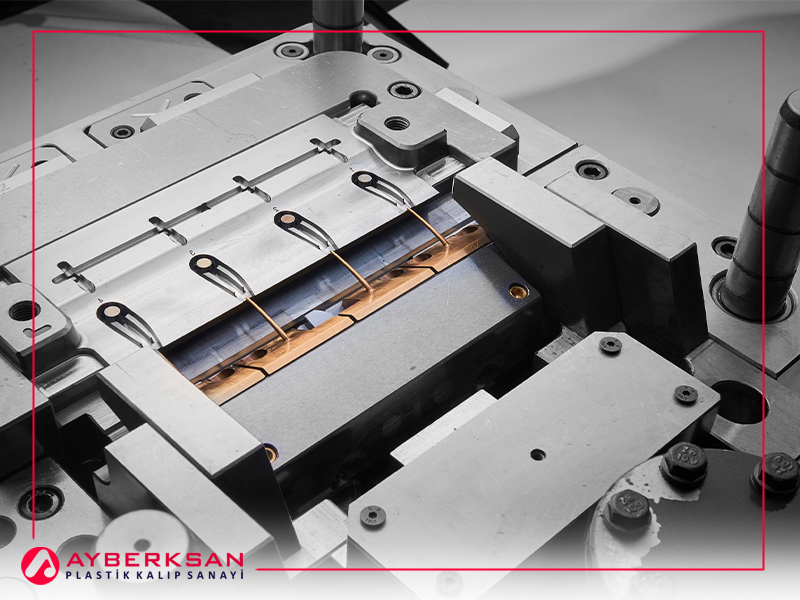

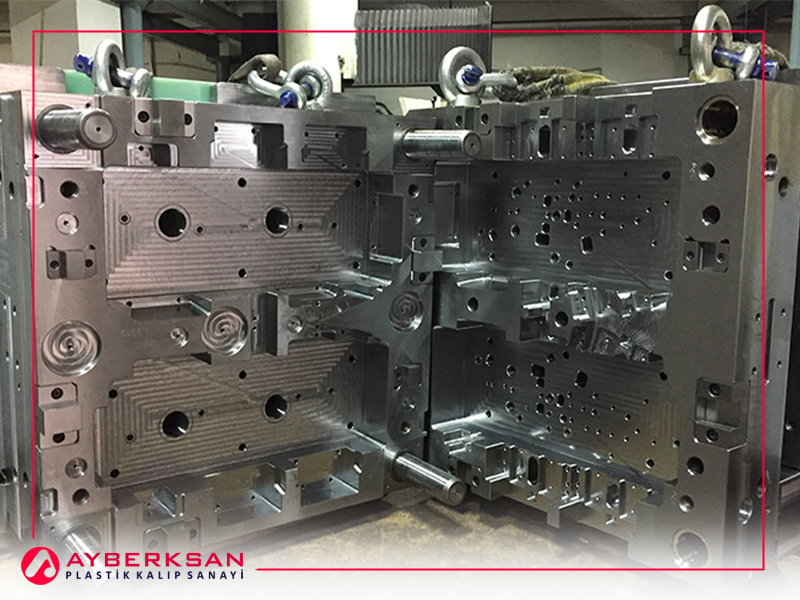

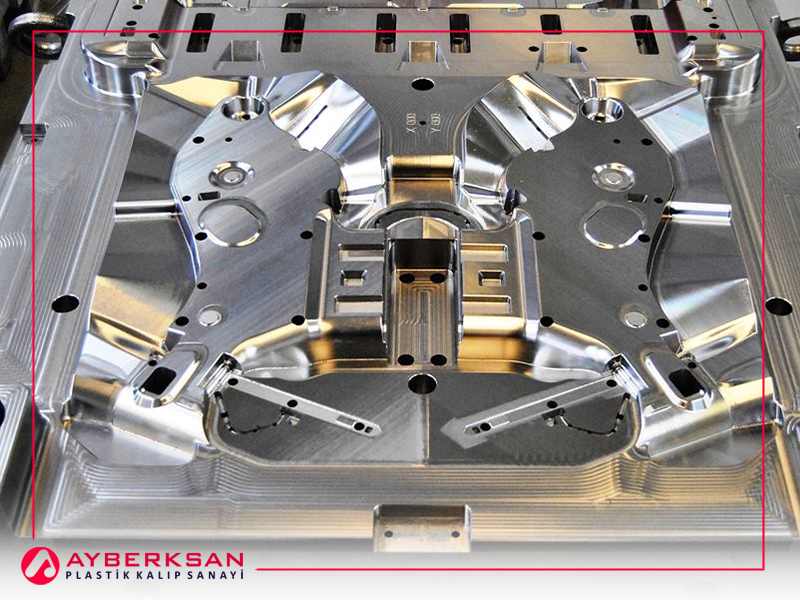

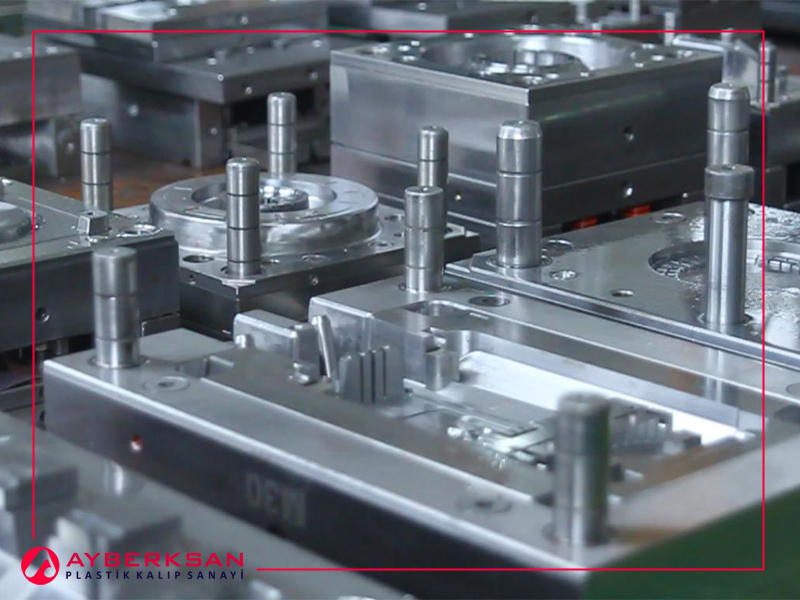

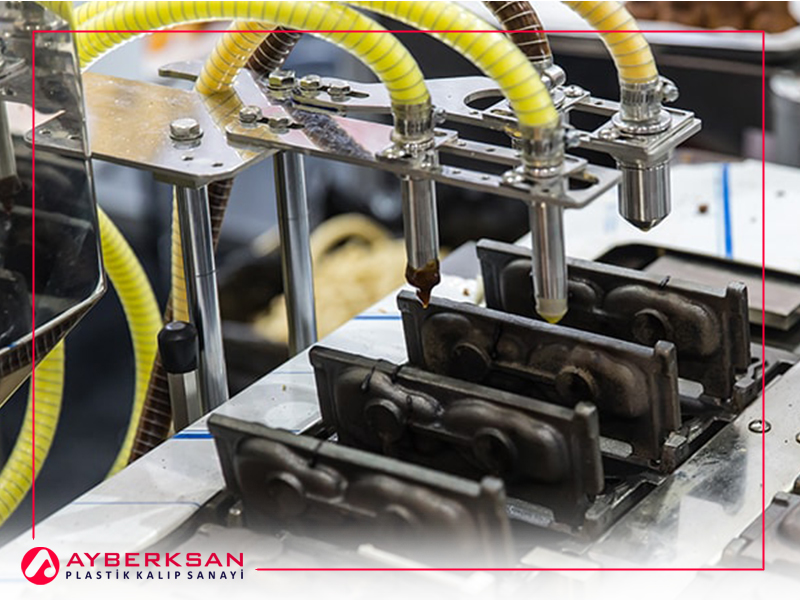

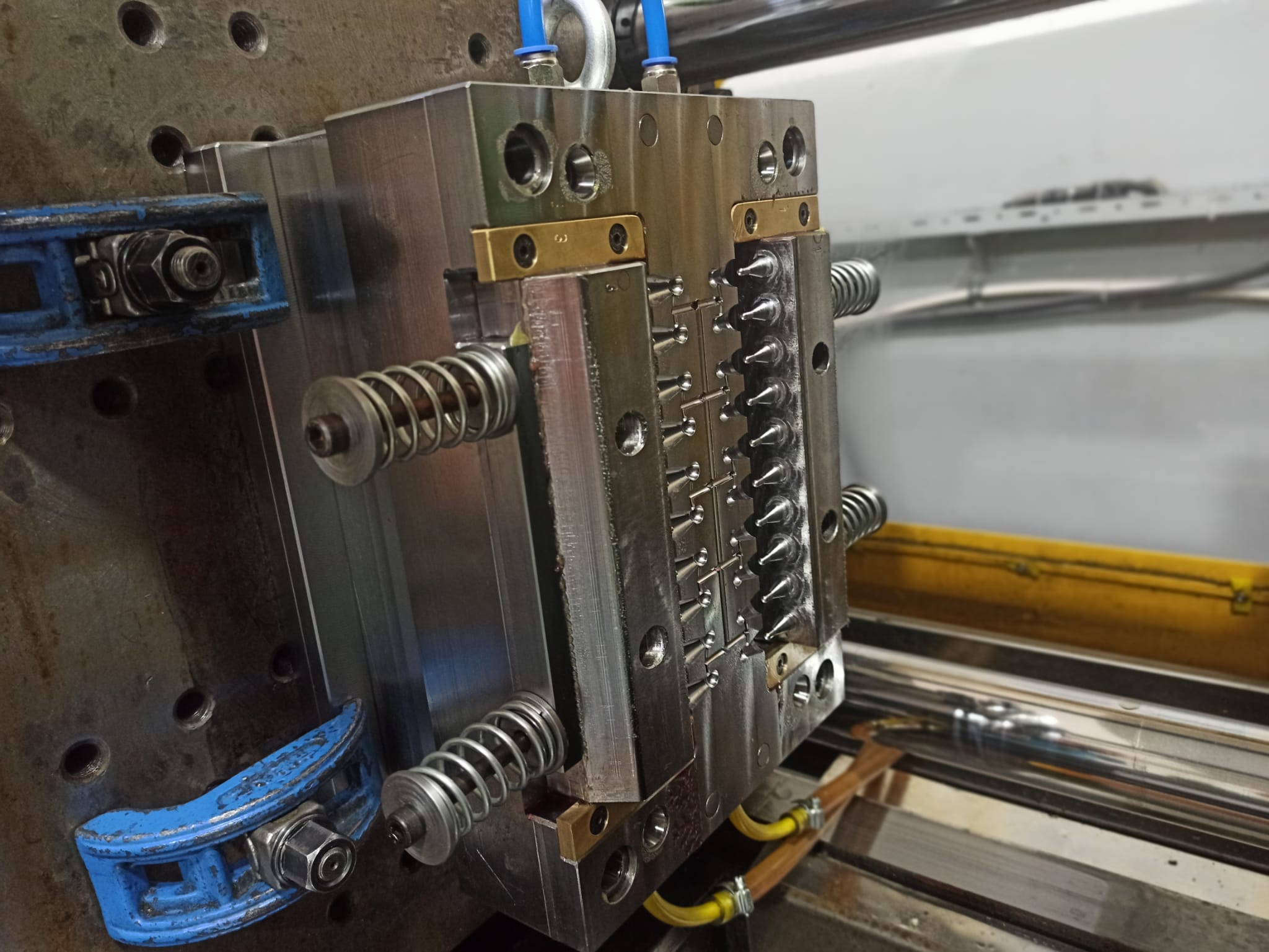

The plastic injection molding machine unit is located at the front of the cylinder and is used to open and close the mold. This system has a fixed plate and a movable plate. Half of the mold is attached to the fixed plate and the other half to the movable plate. In the injection process, the resin in powder and granule form is transferred from the hopper to the cylinder in sufficient quantity with a single application where the material is heated and melted. At the same time, it moves towards the front of the cylinder by being turned by a screw in the cylinder. The axial movement of the screw causes the molten resin to be transported through the nozzle channel at high pressure and filled into the mold cavity. The resin, which takes the shape of the part, remains under pressure until it cools. By adding resin to the nozzle, pressing, and holding stages are applied to balance the shrinkage of the part. After cooling, the moving plate moves forward and opens the mold, and ejects the parts with the help of an ejector.

Injection Mold Manufacturing Advantages

Injection mold manufacturing has many advantages. Injection molding is the most economical technology for producing many identical plastic parts. Once the tool is molded and set on the machine, plastic parts can be produced very quickly and inexpensively. Almost all thermoplastic materials (and some thermosetting resins and silicones) can be injection molded. It offers a wide variety of materials with different physical properties that need to be developed.