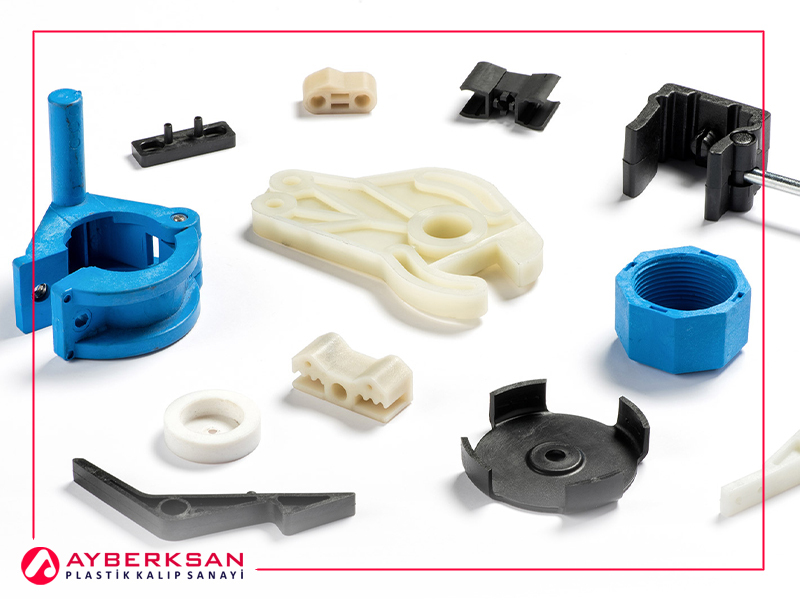

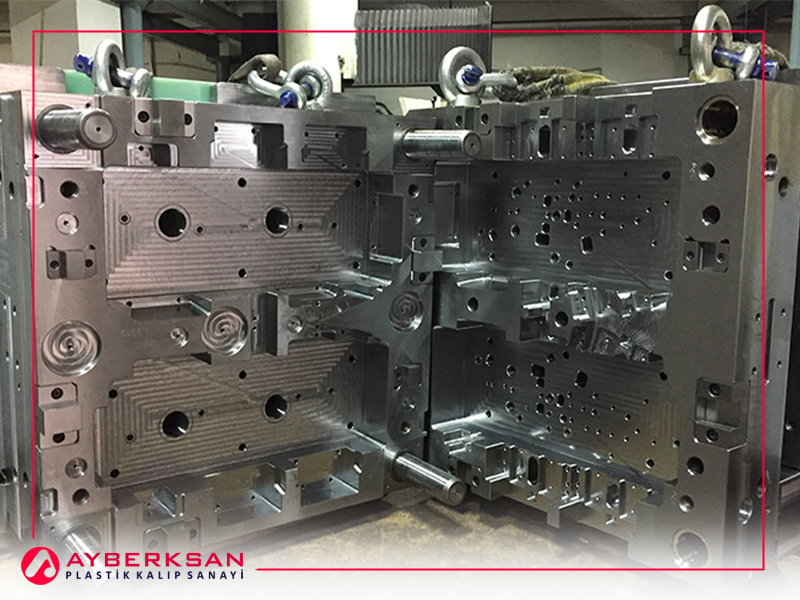

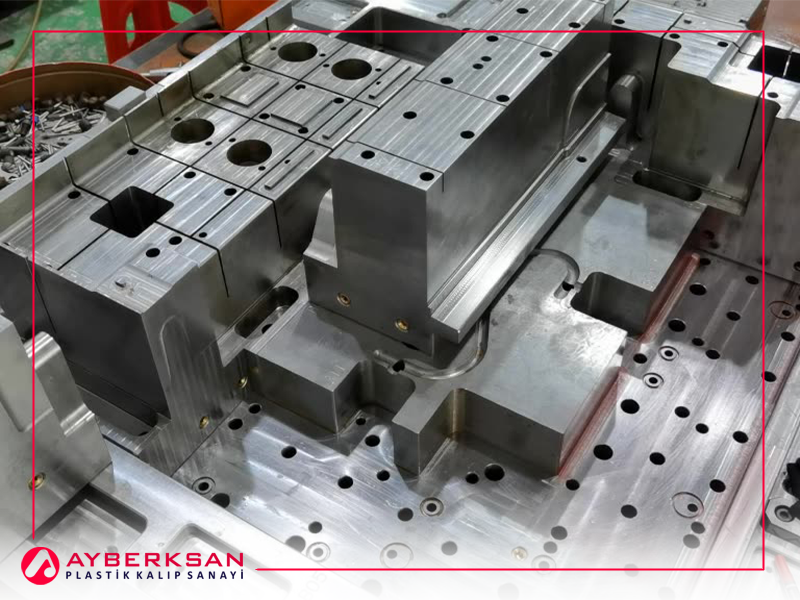

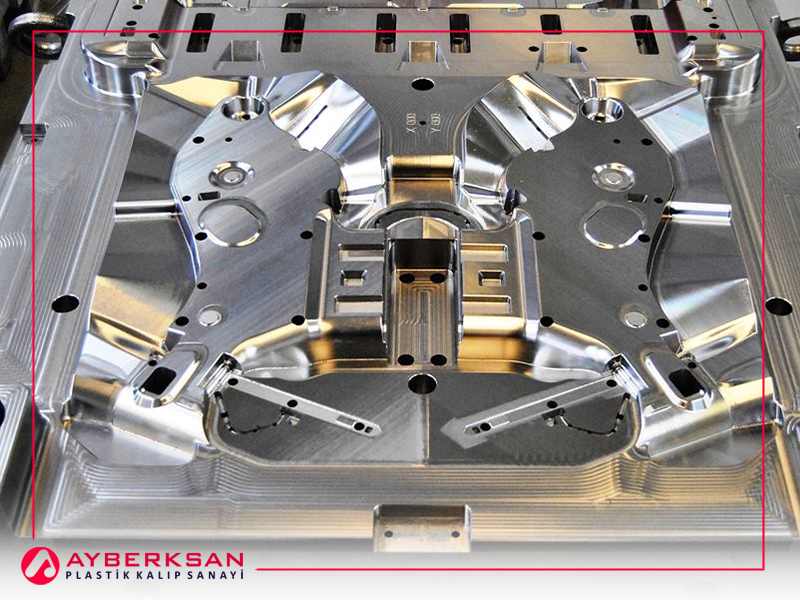

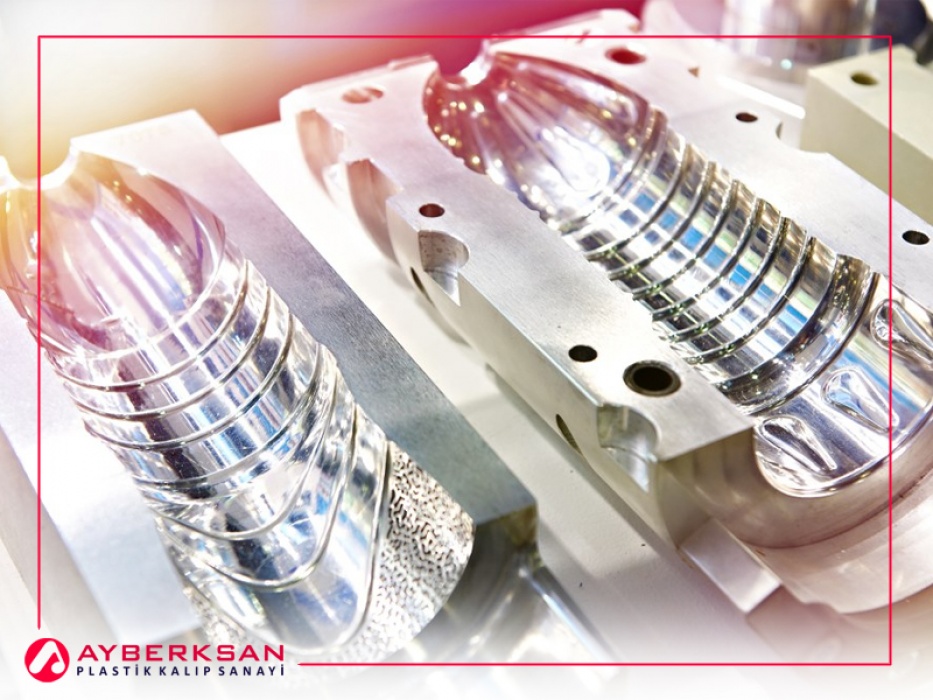

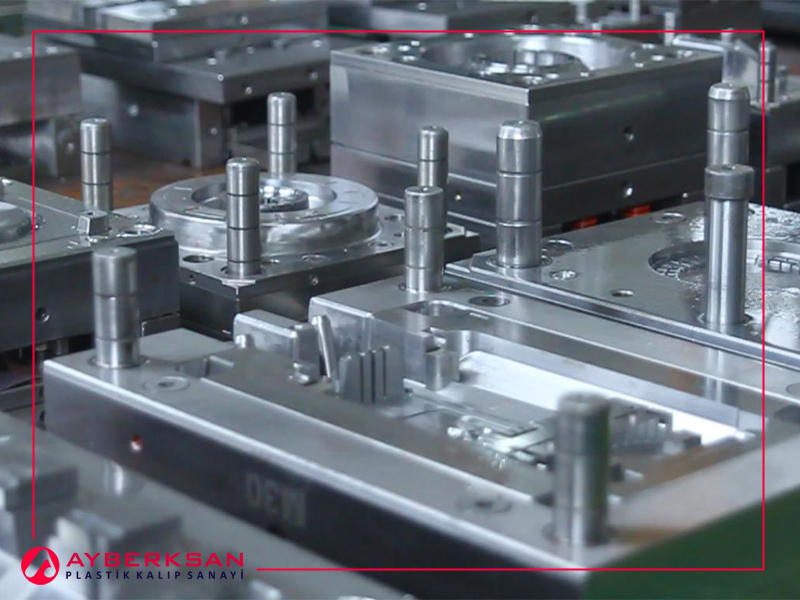

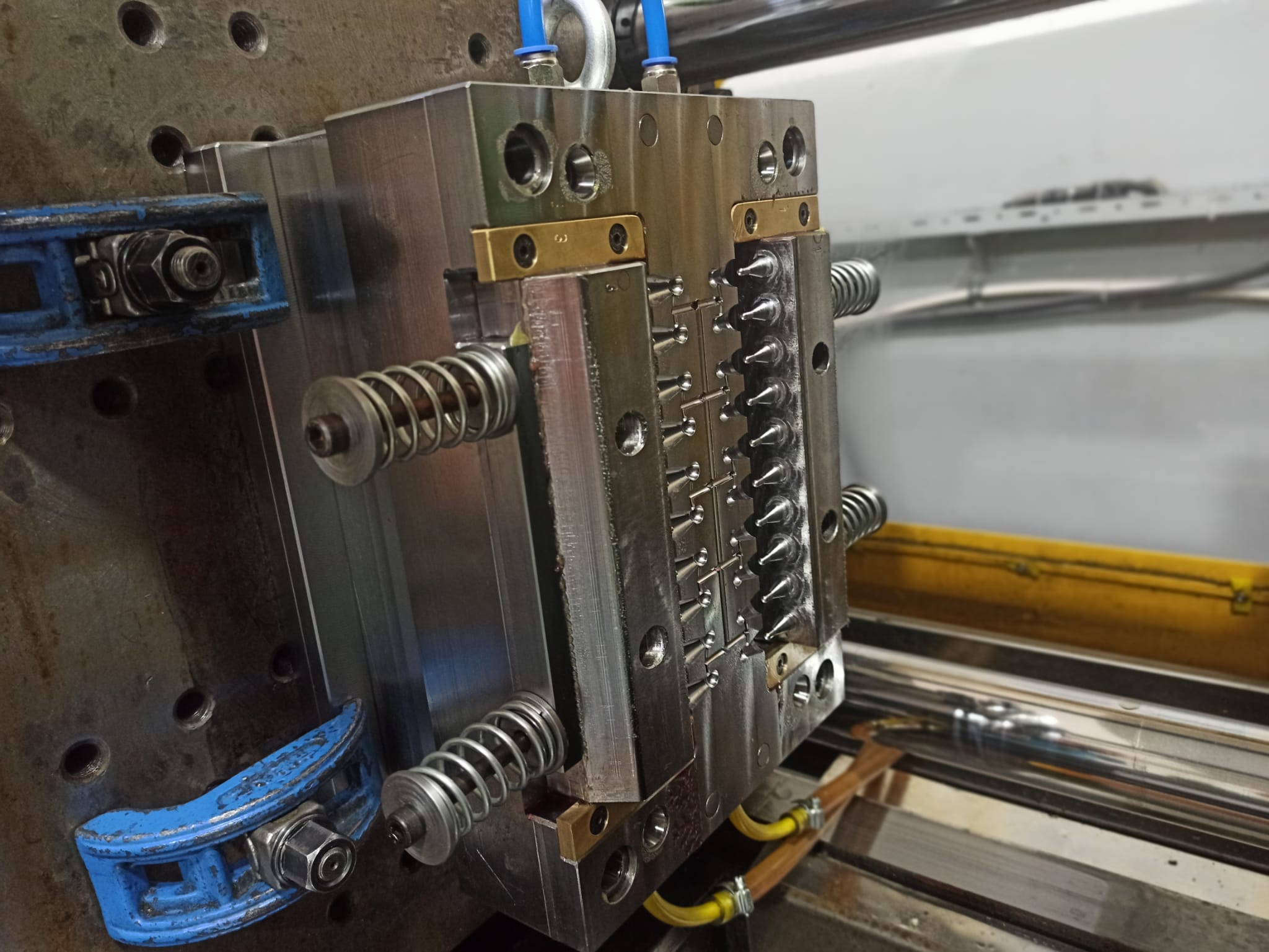

Injection materials consists of the raw material, mold, and the machine that required for the plastic injection molding process. In the plastic injection process, the melted plastic material in the ladle is injected into the mold, and after this process, the melted plastic is cooled and becomes ready for use. Plastic injection molding is the process of shaping and shaping a plastic material made of a polymer by melting it at a high temperature. It is used by highly preferred companies in the industrial sector. The most basic definition of plastic injection molding is to mold the molten plastic raw material by injecting it into a mold using temperature and to obtain a product by cooling the mold and removing it. The production method of plastic injection molding is widely used in the industrial field. From the smallest parts of life to the largest parts, many parts are produced using plastic injection molding.

What Does Plastic Injection Mean?

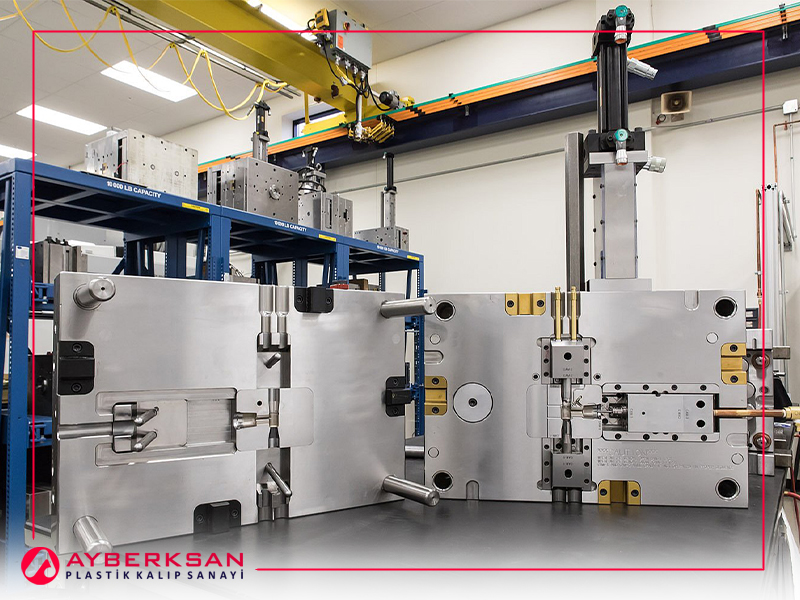

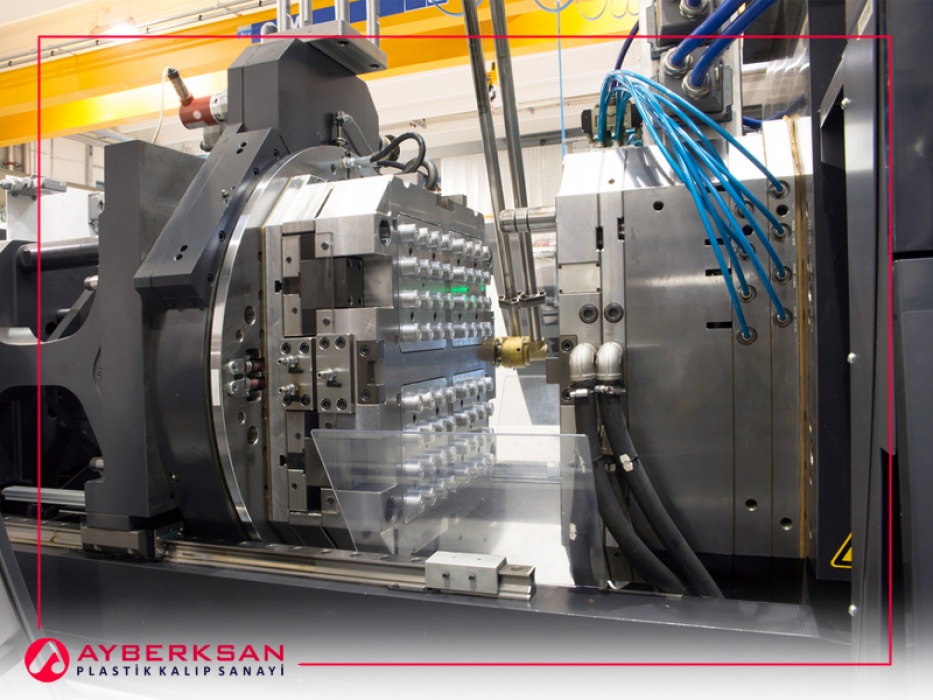

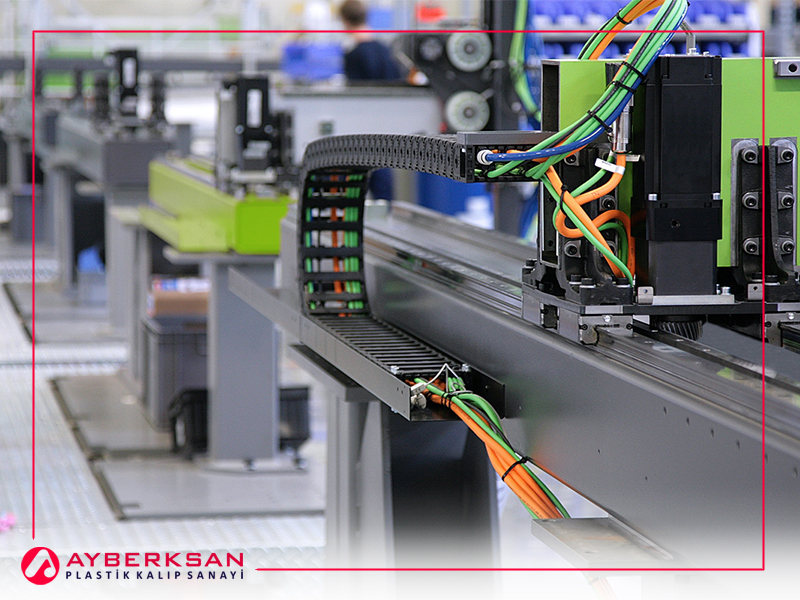

The question of what plastic injection means can be answered by melting the raw materials at high temperatures and injecting them into a mold. The plastic injection molding production process is widely used in the industrial sector. Many products, from the smallest to the largest in life, are manufactured using the plastic injection molding process. In modern industry, plastic injection machines are used by integrating with computer and software systems. A plastic injection machine equipped with the latest technology consists of two main parts, an injection unit, and a molding unit. Therefore, it is necessary to master this technology to perform this injection.

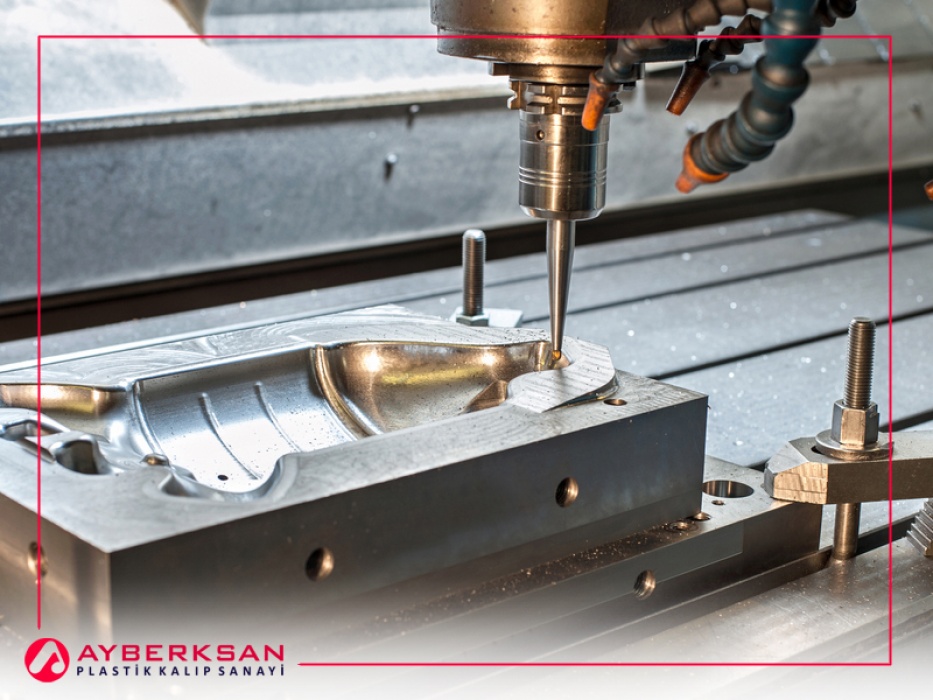

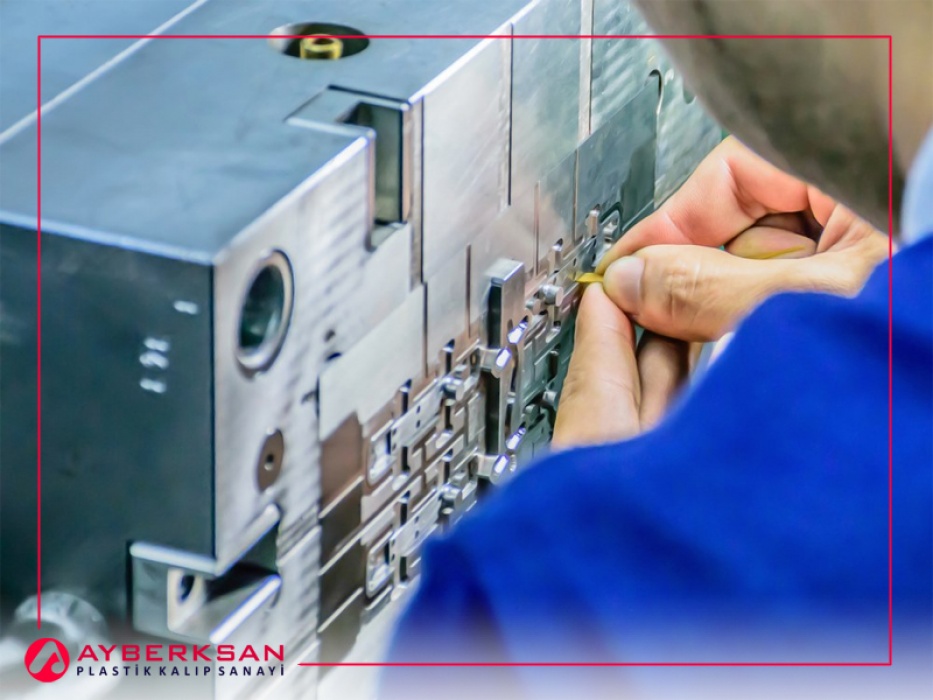

What are the Rules to Know in Plastic Injection Molding?

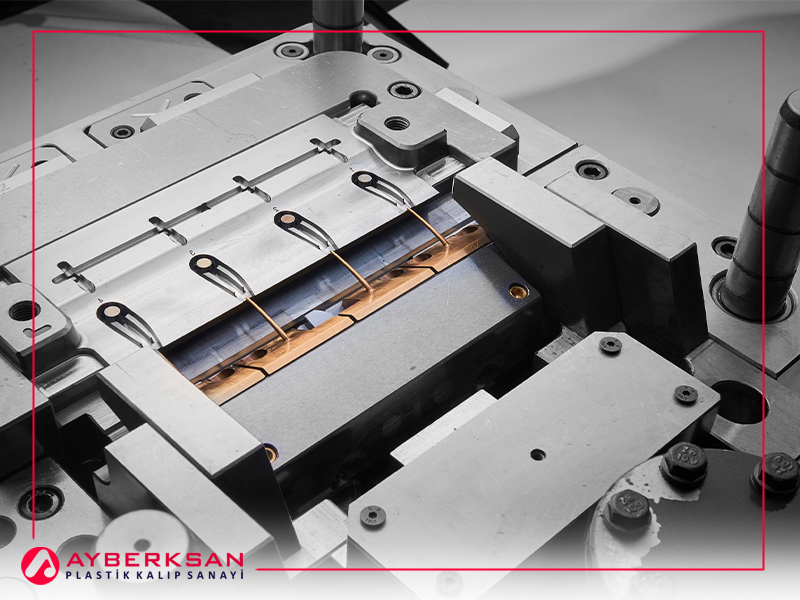

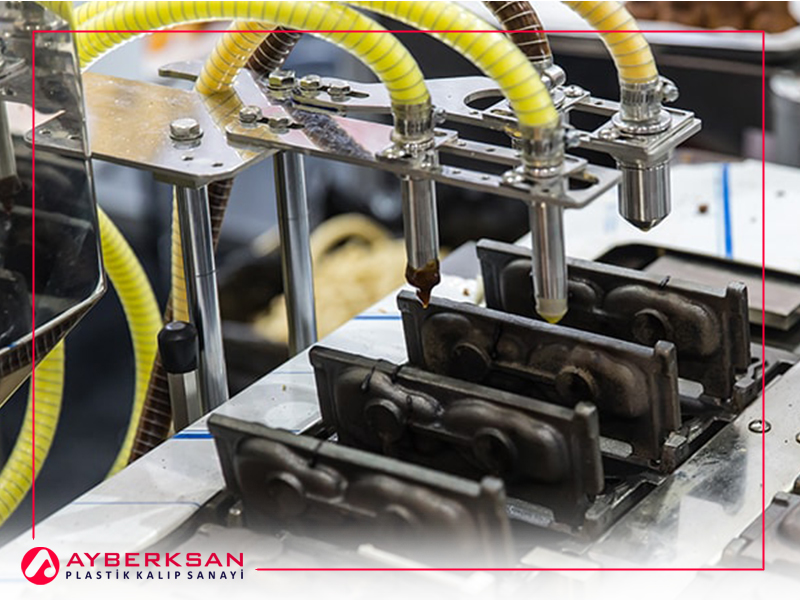

The plastic injection process should be done by a competent company. Otherwise, the plastic injection process may not work properly and the correct product cannot be obtained. To avoid this situation, you need to fully understand the plastic injection molding process. In this respect, it is important to consider the rules and factors to be considered in plastic injection molding. The plastic injection consists of 8 stages. These can be listed as raw material selection, melting at the right temperature, correct mold placement, closing phase of the mold, injection, cooling, mold opening, and ejection. For this reason, you need to work with the most experienced plastic manufacturers in the industry with success in the fields of plastic mold making and plastic injection molding. In this way, it becomes possible to take advantage of many advantages. Thus, you get the right product, and you avoid time and cost loss.